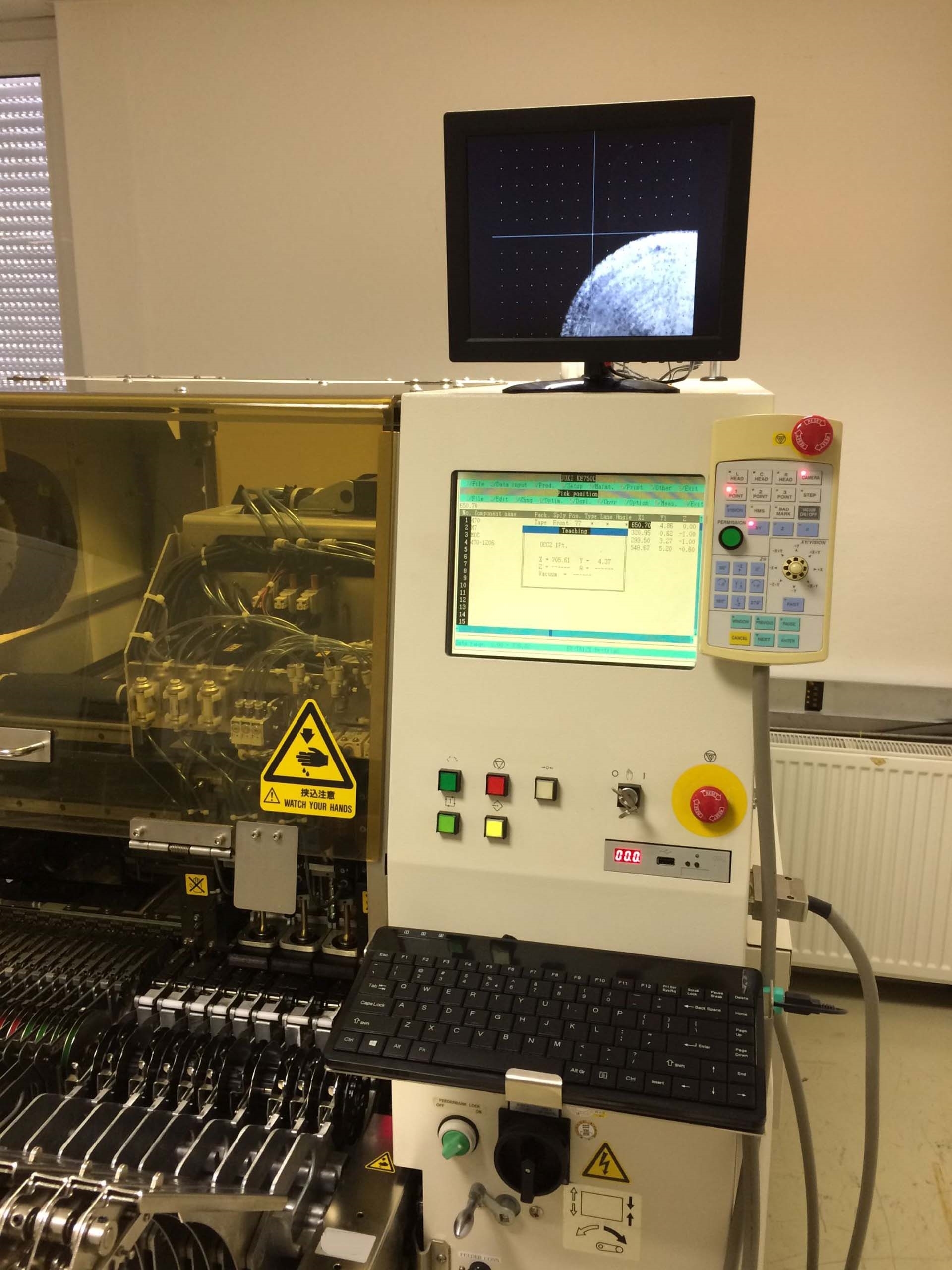

Used ZEVATECH / JUKI 750 #9226854 for sale

URL successfully copied!

Tap to zoom

ID: 9226854

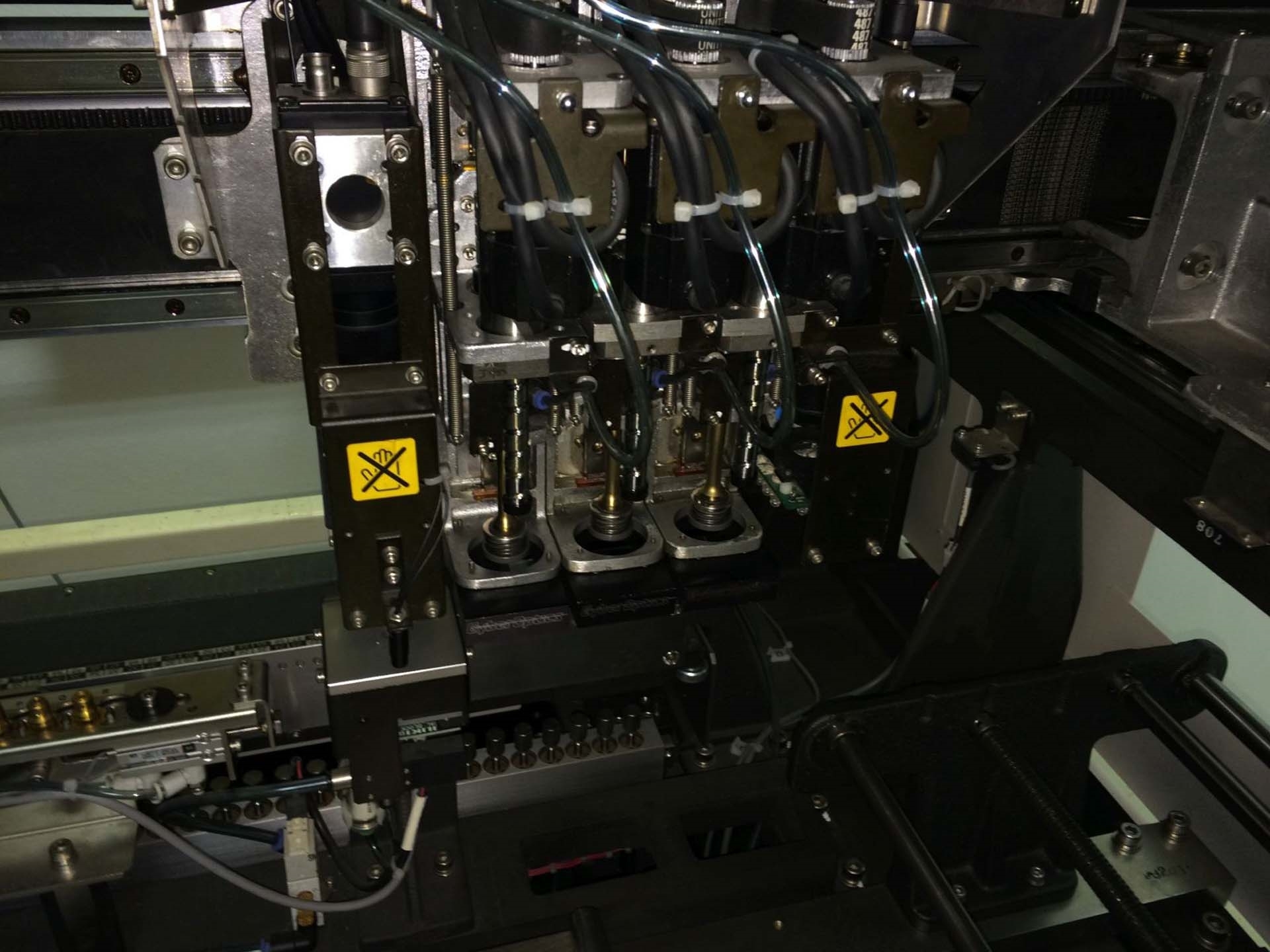

Pick and place machine, parts machine

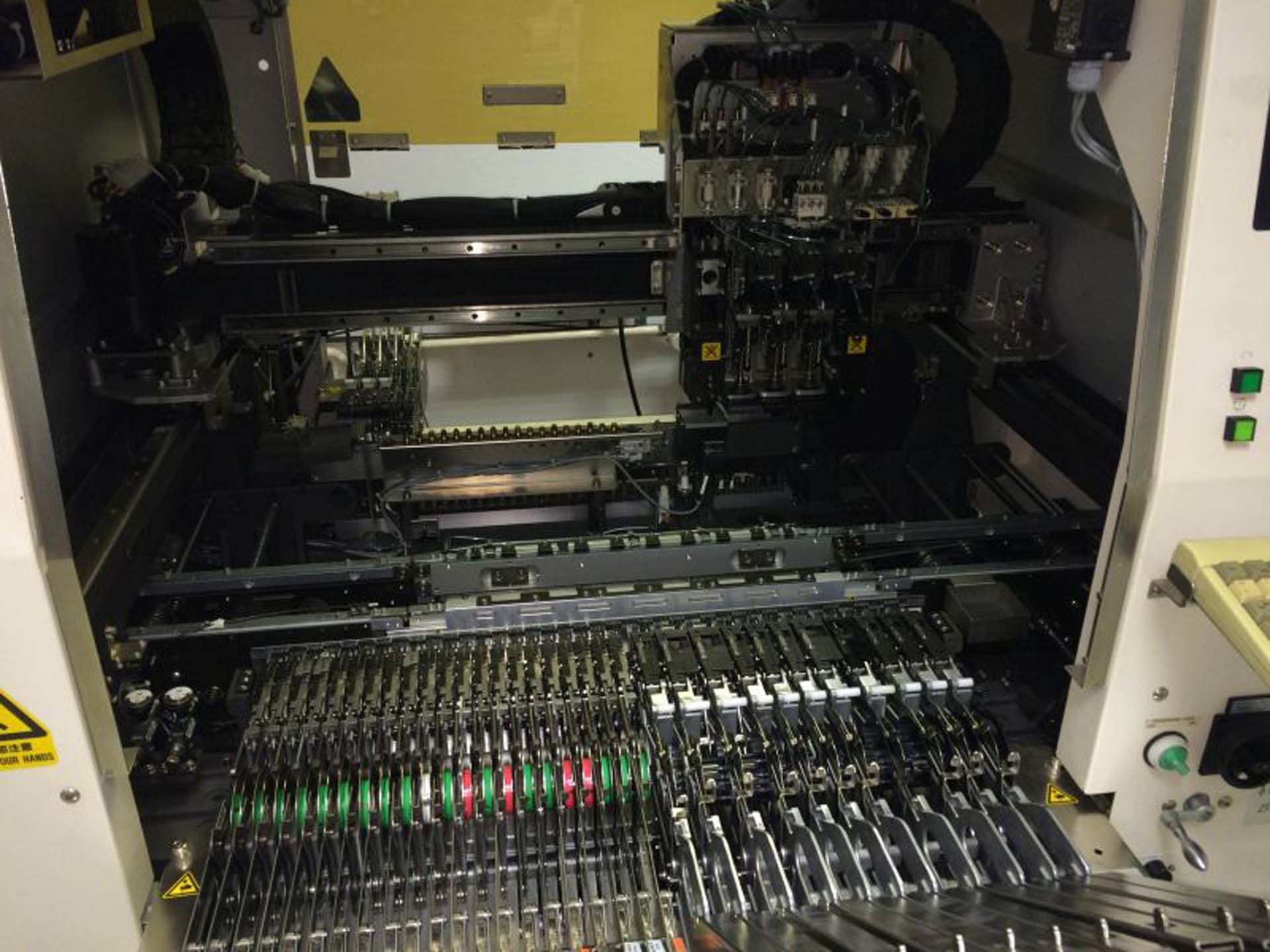

(3) Pipettes

(2) Feeders carts included

Feeders:

(10) 8 mm (NF08)

(50) 8 mm (NF81E)

(10) 12 mm (FF12FS)

(5) 16 mm (FF16FS)

(3) 24 mm (FF24FS)

Vibration

Accessories:

(18) Nozzles (101x3, 102x3, 103x3, 104x3, 105x2, 106x2 + Some extra)

Cart with aligning

Cart without align mark

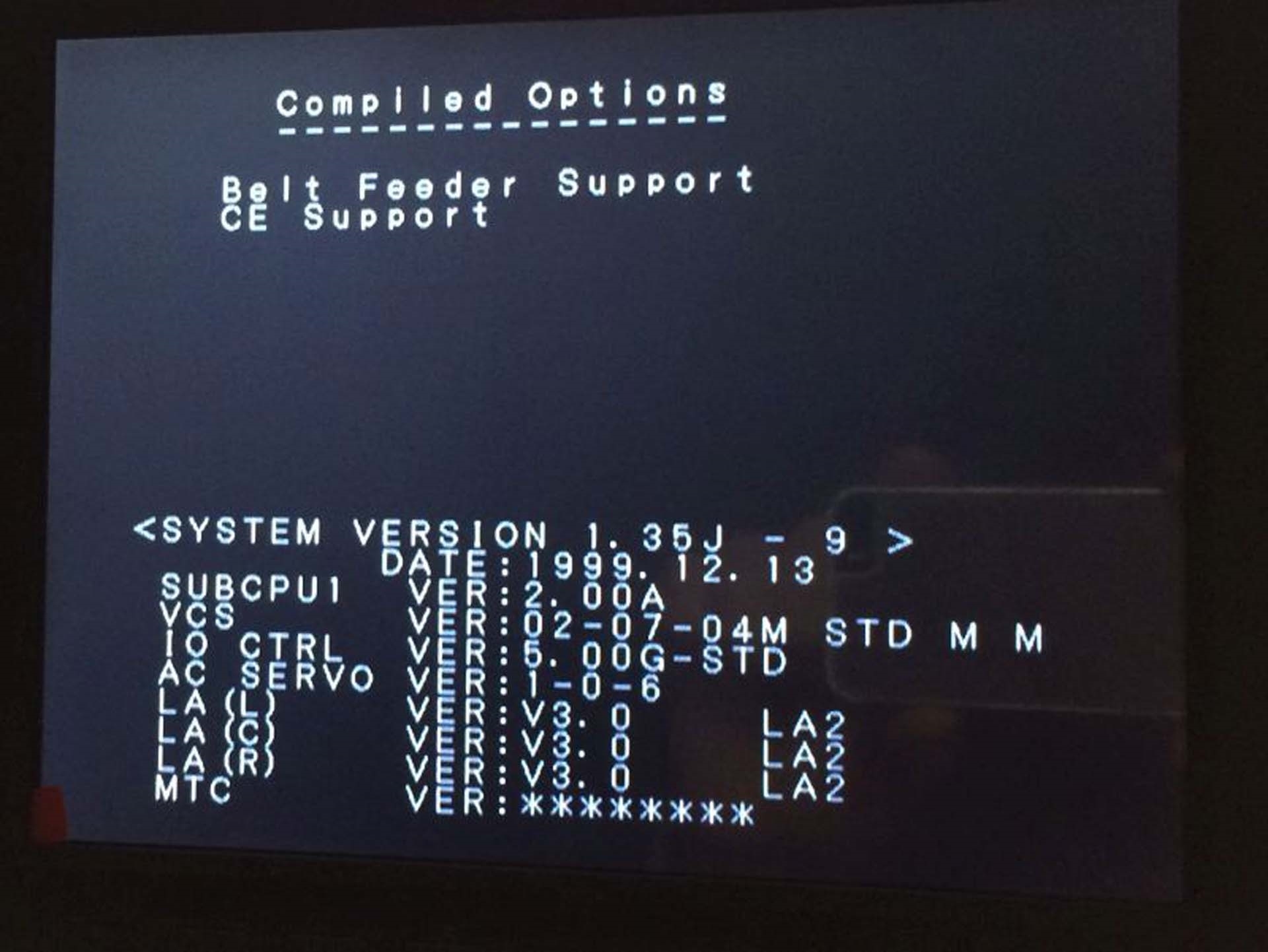

Upgrades:

PC LCD Upgraded to LED backlight

FFD, 3,5" has been replaced by USB emulator

HDD Upgraded to SSD

CRT Monitor was replaced by LCD, 10"

Keyboard

Air filters

Vacuum filters

Manuals included

Includes:

Motors

Belts

Boards

PC With LCD

Vibration table

Spare parts.

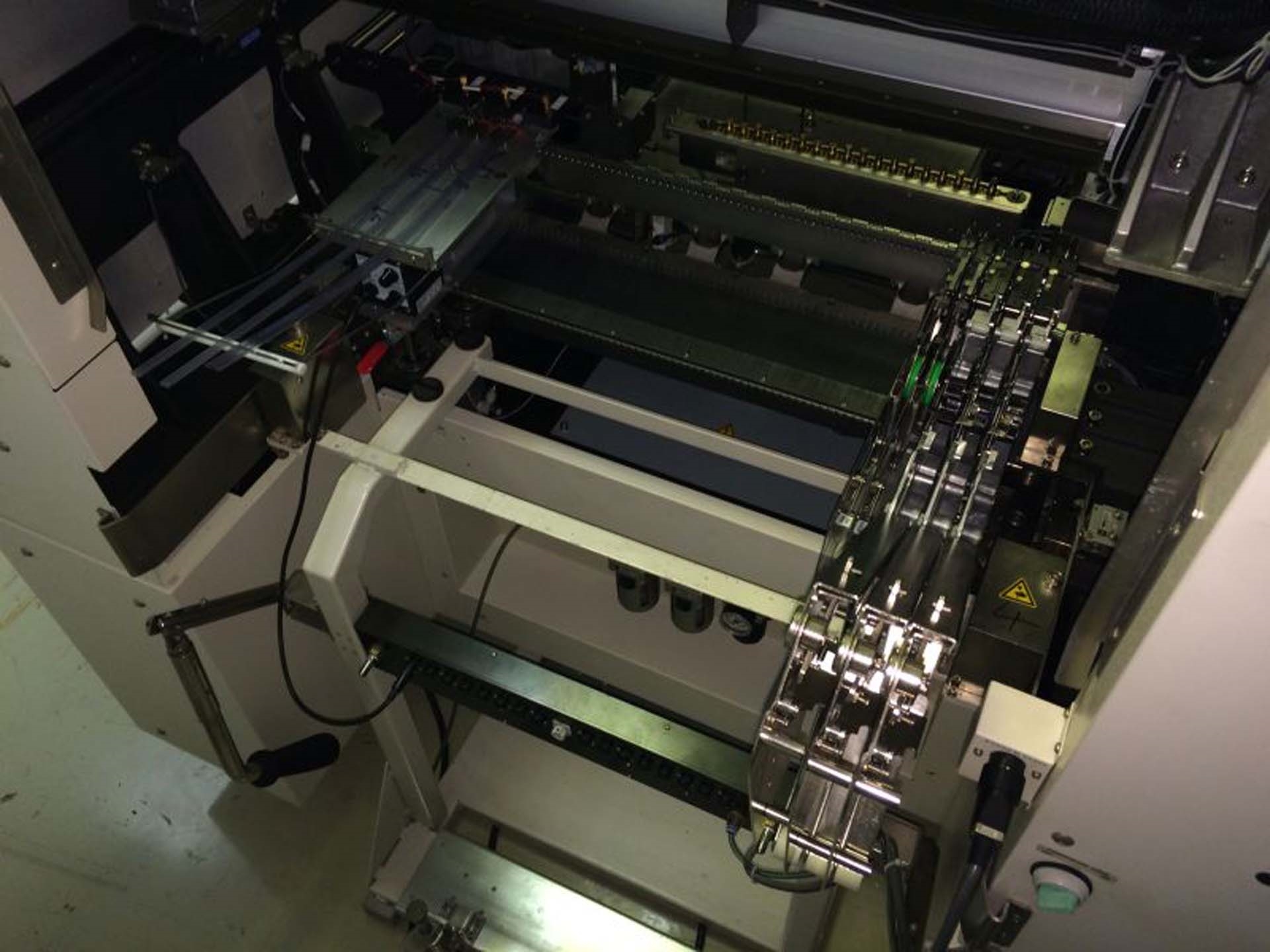

ZEVATECH / JUKI 750 is an advanced PC Board Assembly and manufacturing equipment used for medium to high mix and low to medium complexity projects. This system is designed to meet the rigorous demands of both surface mount (SMT) and through hole (THT) customers with support for a wide array of technologies such as flip chip, BGA, µ-BGA, CSP and QFN. JUKI 750 unit is built upon a modular concept providing unparalleled flexibility in adapting to today's changing production environments. It consists of an integrated handling machine which is able to store up to 16 components, an innovative dual-stage placement head that offers high-speed picking capabilities, and a fully automated set-up, programming, calibration, and operation process. To maximize production output and reduce interference with other equipment on the line, ZEVATECH 750 is transported by a motorized conveyor, instead of a typical conveyor belt. This allows for precise positioning of the tool at any angle needed. Efficiency is further increased through the use of a multi-functional feeder asset accepting both tray and tape-and-reel components, eliminating setup time typically associated with the manual organization of parts. 750 offers excellent flexibility through its programming capabilities, which can be fully customized based upon customer needs. A high level of process control is also achieved through its 3-Dimensional vision technology, which helps to detect and correct misalignment issues. It is also equipped with a dual-stage placement head, allowing for double placement of components and increased throughput of the production line. In addition, ZEVATECH / JUKI 750 is designed with operator safety in mind. It has built-in proximity sensors, preventing inadvertent movement of the model when operators are in close proximity. It also offers a compressive air filtration equipment which helps to reduce airborne particles from the environment. Overall, JUKI 750 is a robust and reliable system that provides an efficient solution to PC Board Assembly and manufacturing needs. Its modular design, enhanced programming capabilities and 3-Dimensional vision technology make it ideal for a wide range of applications in the electronic manufacturing sector.

There are no reviews yet