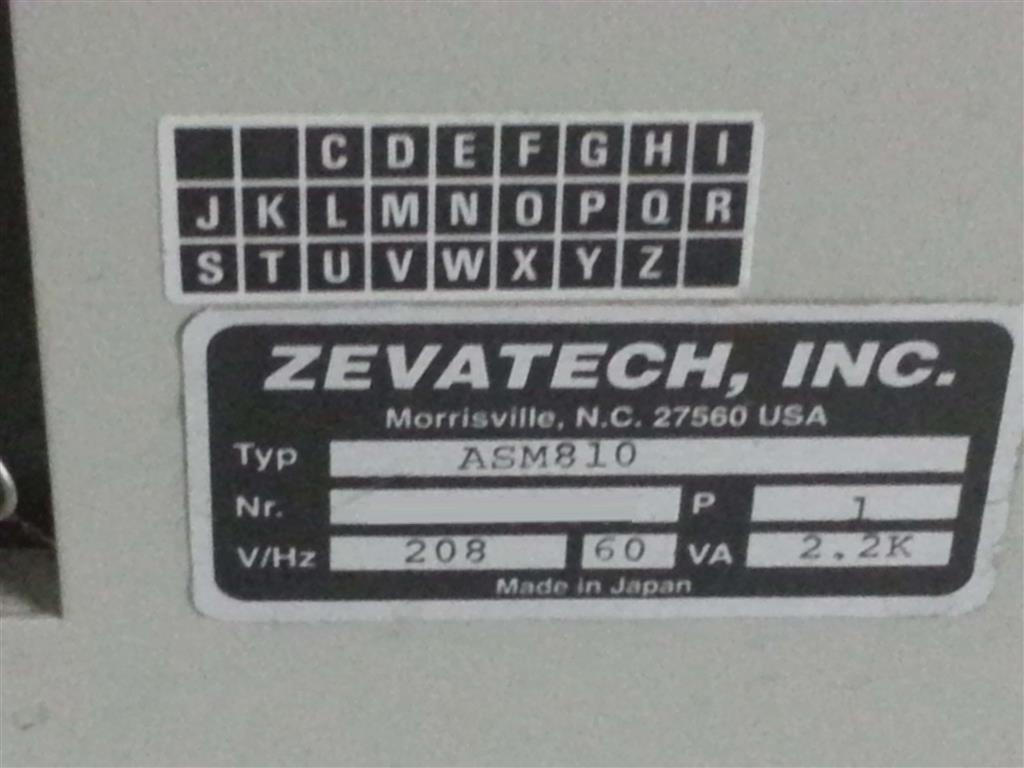

Used ZEVATECH / JUKI ASM 810 #9109019 for sale

URL successfully copied!

Tap to zoom

ID: 9109019

Pick and place machine

Dual placement heads

Multilevel programmable centering

Board offset correction

Component verification

CAD Input

Fine pitch placement

0402’s to PLCC 100’s

Board size: 18” x 20”

Includes:

(47) 8 mm feeders

(8) 12 mm feeders

(6) 16 mm feeders

(2) 24 mm feeders.

ZEVATECH / JUKI ASM 810 is a high-performance, cost effective solution for pc board assembly and manufacturing. The equipment is comprised of two integrated machines, JUKI Alignment Station (ZAS) and ZEVATECH Laser Powered Modular Placement System (LPMP). The two machines work in tandem to provide a fast and efficient way to assemble high-density printed circuit boards (PCBs). The ZAS provides a hardware interface between the PC board and the LPMP. It features precision camera-based components that can detect small features on a PCB, such as chip and via locations, as well as alignment. This allows for pinpoint accuracy between the PCB and the LPMP. This also ensures that components will get placed precisely as intended. ZEVATECH / JUKI LPMP, on the other hand, is a laser-based pick and place unit. It uses high-speed, high-precision laser optics to detect components on the board, pick them up and place them accurately in their designated locations. The machine is capable of placing components as small as 0603 sized SMT components and as large as 75mm x 75mm chip components. At its maximum speed, the LPMP processes up to 9000 components per hour and 2000 components per hour when working at its slower speed. JUKI ASM 810 tool has a user-friendly design that can be programmed through its graphical user interface. The interface features a parts list builder, component library and alignment diagnostic tools, all of which help with the accuracy of component placement. The asset also includes built-in vacuum systems and component handlers, as well as built-in safety features. ZEVATECH ASM 810 is an ideal model for high-volume production runs of even the most complex PCBs. The equipment is reliable, fast and efficient while maintaining a high-level of accuracy and precision. With its small footprint and low maintenance, this system offers a competitive option for any assembly and manufacturing requirements.

There are no reviews yet