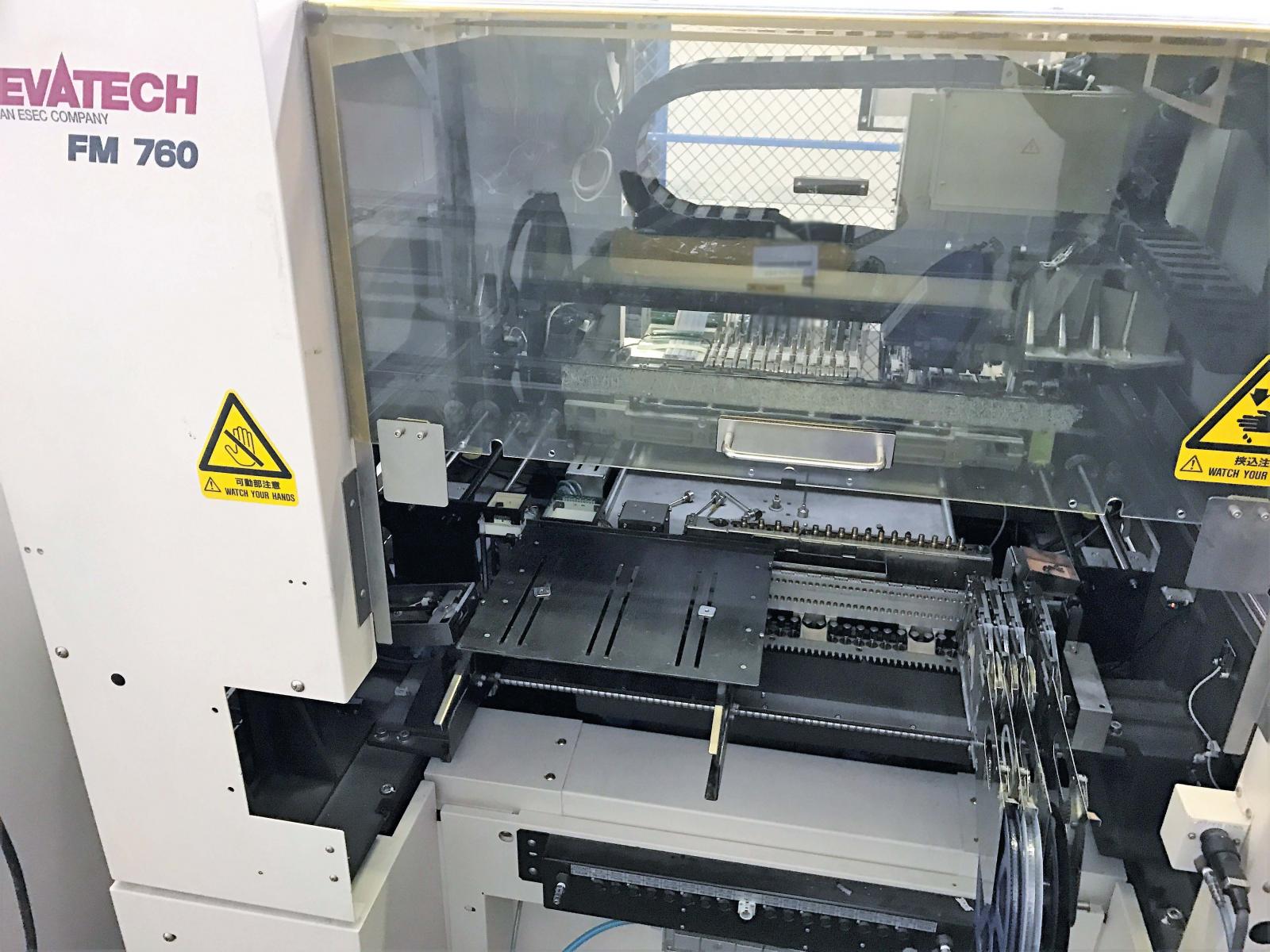

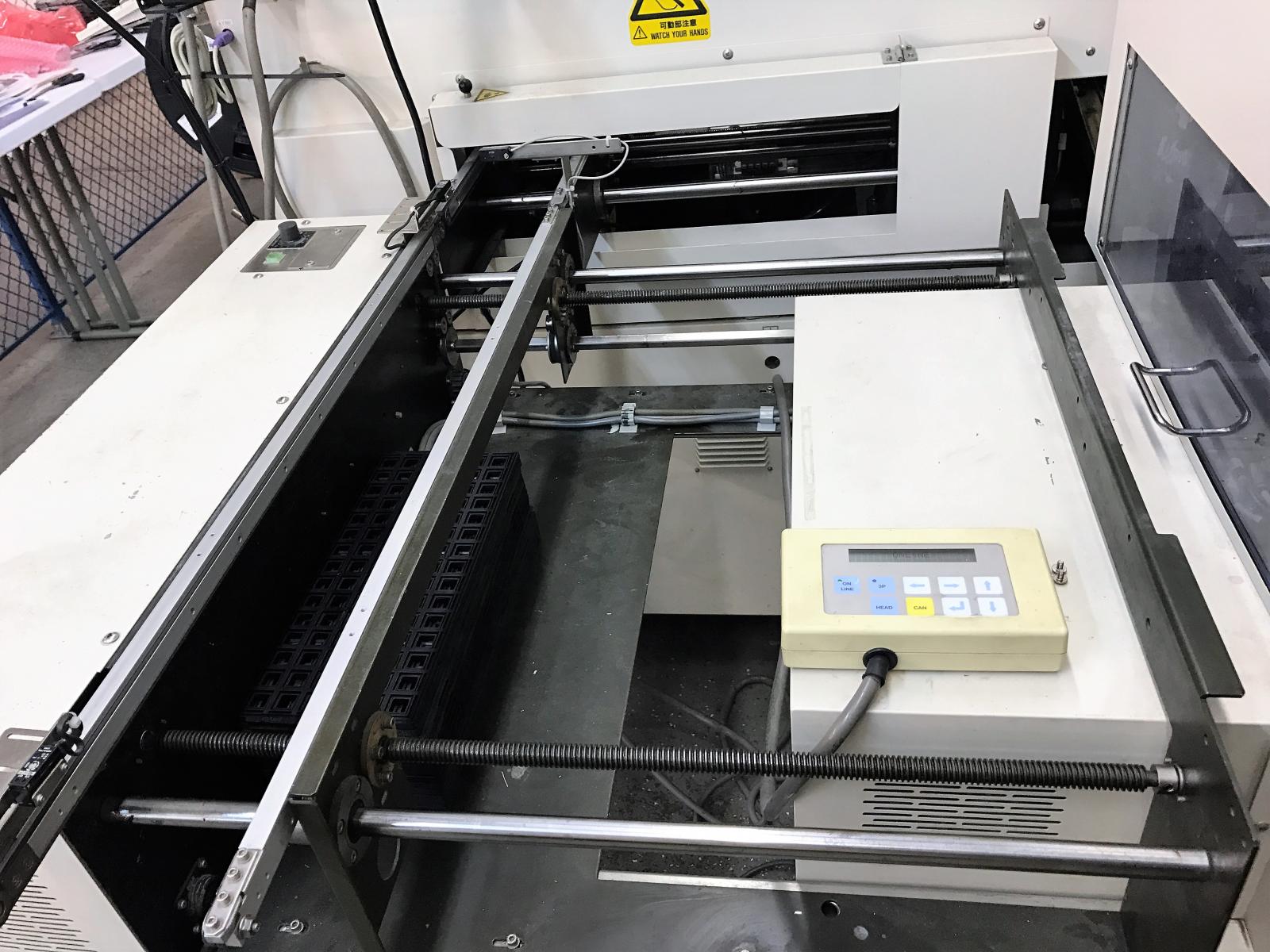

Used ZEVATECH / JUKI FM 760 #9185575 for sale

URL successfully copied!

Tap to zoom

ID: 9185575

Vintage: 2005

Pick and place machine

Tray

Feeder

Tray loader: TD-3D

Maximum board size: 18" x 20"

Front feeder trolley cart

Rear fixed feeder bank

Heads:

LA

LAIC

OCC Camera

Bad mark sensor

Shape clamp

IC Conveyor belt

VCS Upward camera

BGA Ball

Additional upgrade:

Second upward looking micro BGA camera VCS 27.5mm

Ball

Belt feeder support

Manual included

2005 vintage.

ZEVATECH / JUKI FM 760 is a fully-automated PC board assembly and manufacturing equipment designed for a wide range of industry applications. It features easy-to-use, advanced functions to meet the needs of high-precision and high-speed assembly requirements. The system is equipped with a highly-customizable universal dual-axis mounter and can be used to assemble boards with components of up to 40mm in size. The assembly process includes pick-and-place, tape feeders, through-hole and lead-free solder paste printing. JUKI FM 760's dual-axis mounter is designed with a vision unit for applying precise placement of fine pitch components onto a printed circuit board (PCB). It also has a feeder flexibility ranging from 3 slide to 8 slide for tape products of up to 40mm. The mounter further allows for vibration and force control for enhanced accuracy in the assembly process. The machine's integrated Fiducial mark tool enables recognition of X and Y Fiducial marks for complex placement and also compensates for multiple variations in tape and printed circuit boards (PCBs). ZEVATECH FM 760 has two types of capabilities that allow for efficient and high-precision assembly: Pick-and-place and dual-dispensing. The Pick-and-place uses vision to recognize components on a PCB, while the dual-dispensing uses a precision dispensing valve for precise SMT component locations. The tool also offers exceptional solder paste printing capabilities, supporting salein paste, solder reel paste and solder bump printing with the option for adding mask-dot and maximum dot printing. A barcode reader can be implemented to enable automated assembly from a barcode-labeled production kit. FM 760 features a compact design that can quickly fit into a small production space. It is also a low-maintenance asset, meaning that the model includes few liquid/gas components and requires minimal monitoring and maintenance. The production kit process is highly reliable to ensure accuracy and consistency in assembly. Overall, ZEVATECH / JUKI FM 760 is an effective and reliable PC board assembly and manufacturing equipment that provides excellent advanced features enabling high-precision and high-speed assembly. The system offers easy to use pick-and-place motion control, dual-dispensing, vision recognition, solder paste printing and barcode reader options to fit wide range of production requirements.

There are no reviews yet