Used ZEVATECH / JUKI FS 710 #95271 for sale

URL successfully copied!

Tap to zoom

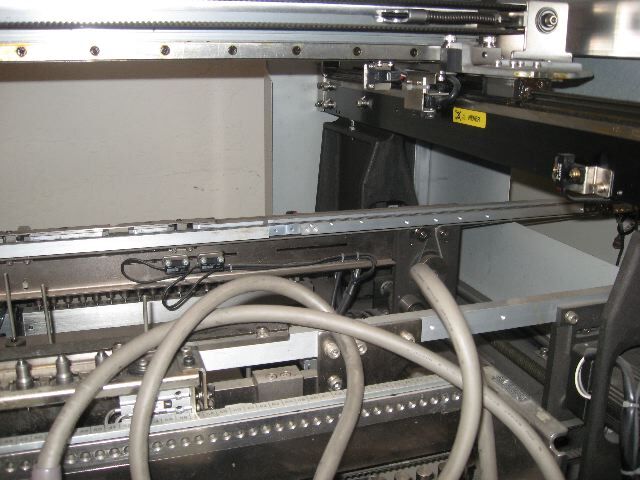

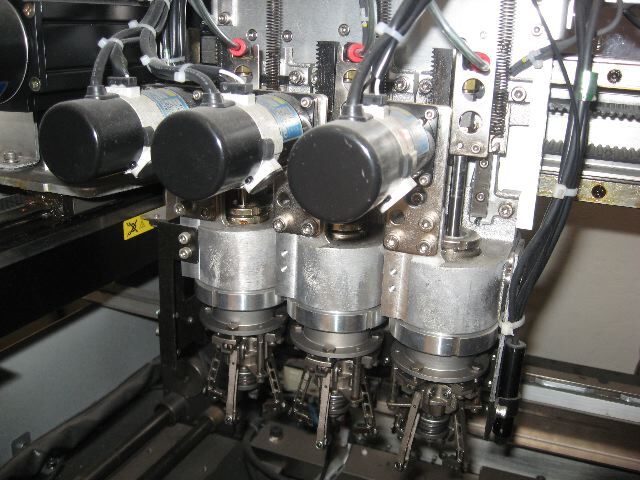

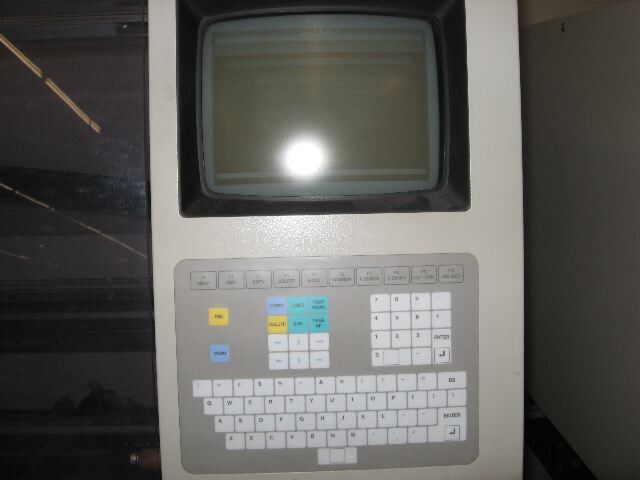

ZEVATECH / JUKI FS 710 is a state-of-the-art PC board assembly and manufacturing equipment produced by JUKI. This highly efficient system is perfect for small to medium sized circuit board production and engineering projects. Utilizing advanced component placement technology, JUKI FS 710 provides speed and accuracy with a variety of sophisticated features. ZEVATECH FS 710 is capable of multiple functions including, component placement, reflow soldering and selective soldering. With the Flip-Chip Flex Feeder, the placement accuracy is extraordinary with an accuracy rating of 0.01mm. This ensures each component is consistently placed in the precise location. In addition, FS 710 is equipped with a lead-free compatible reflow unit that features high stability, optimum temperature control and rapid cooling. Both single- and double-sided boards can be loaded at the same time, allowing for high throughput and greater productivity. ZEVATECH / JUKI FS 710 also makes use of the Auto Reject Center (ARC) which automatically rejects any board that has missed components or other components that did not place within tolerance. JUKI FS 710 also has a built-in vision machine to detect wrong components, and the placement head can be configured through a programming language called PMCPL (Programmable Machine Control Programming Language). This language allows for custom placement algorithms and can be used to create movement instructions for the placement and soldering head. ZEVATECH FS 710 tool is ideal for manufacturers looking for a reliable PC board assembly asset with easy setup and high efficiency. FS 710 also comes with a variety of advanced functions, making it the perfect choice for companies seeking a specially tailored production setup.

There are no reviews yet