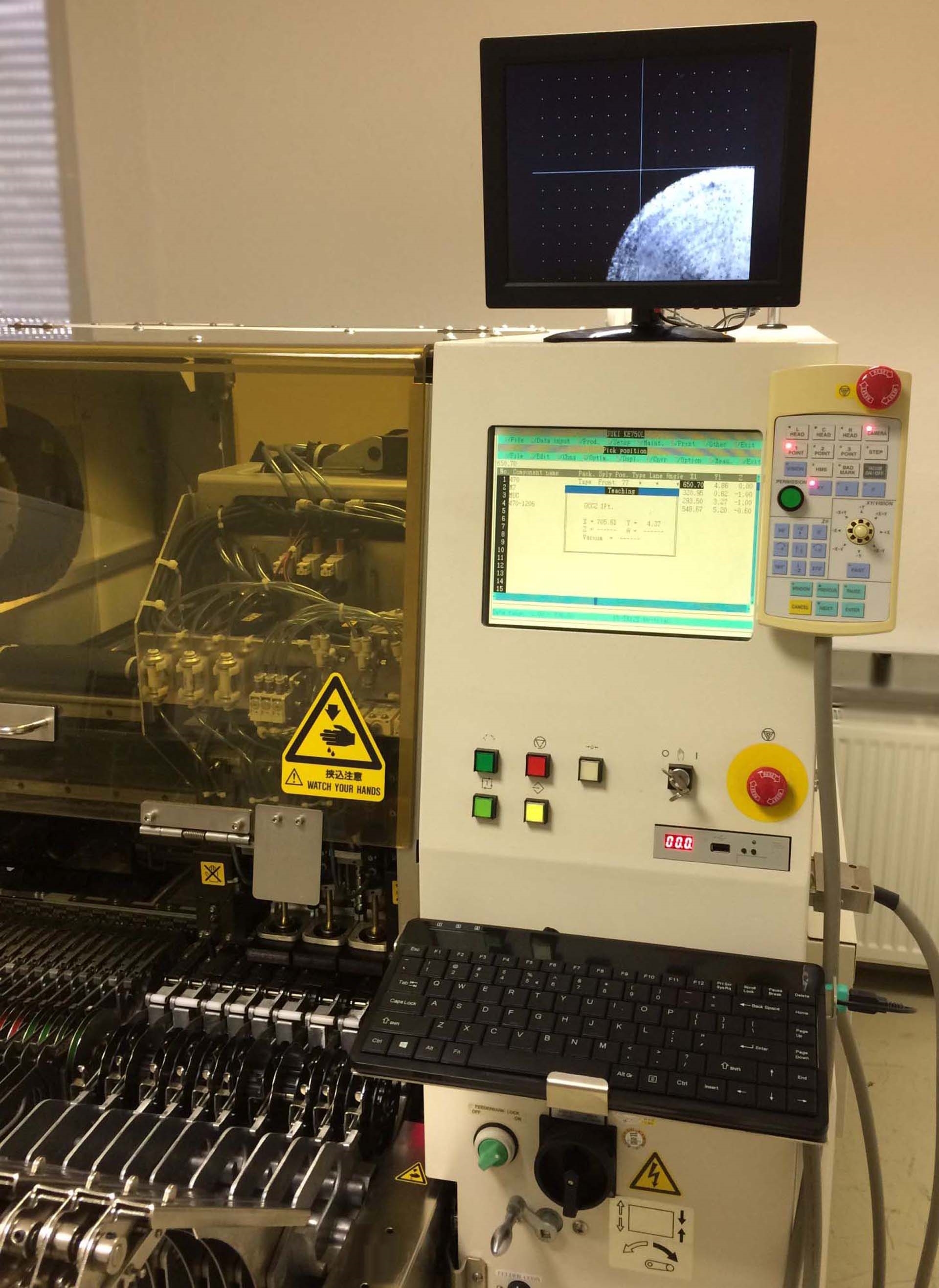

Used ZEVATECH / JUKI FS 750 #9230224 for sale

URL successfully copied!

Tap to zoom

ID: 9230224

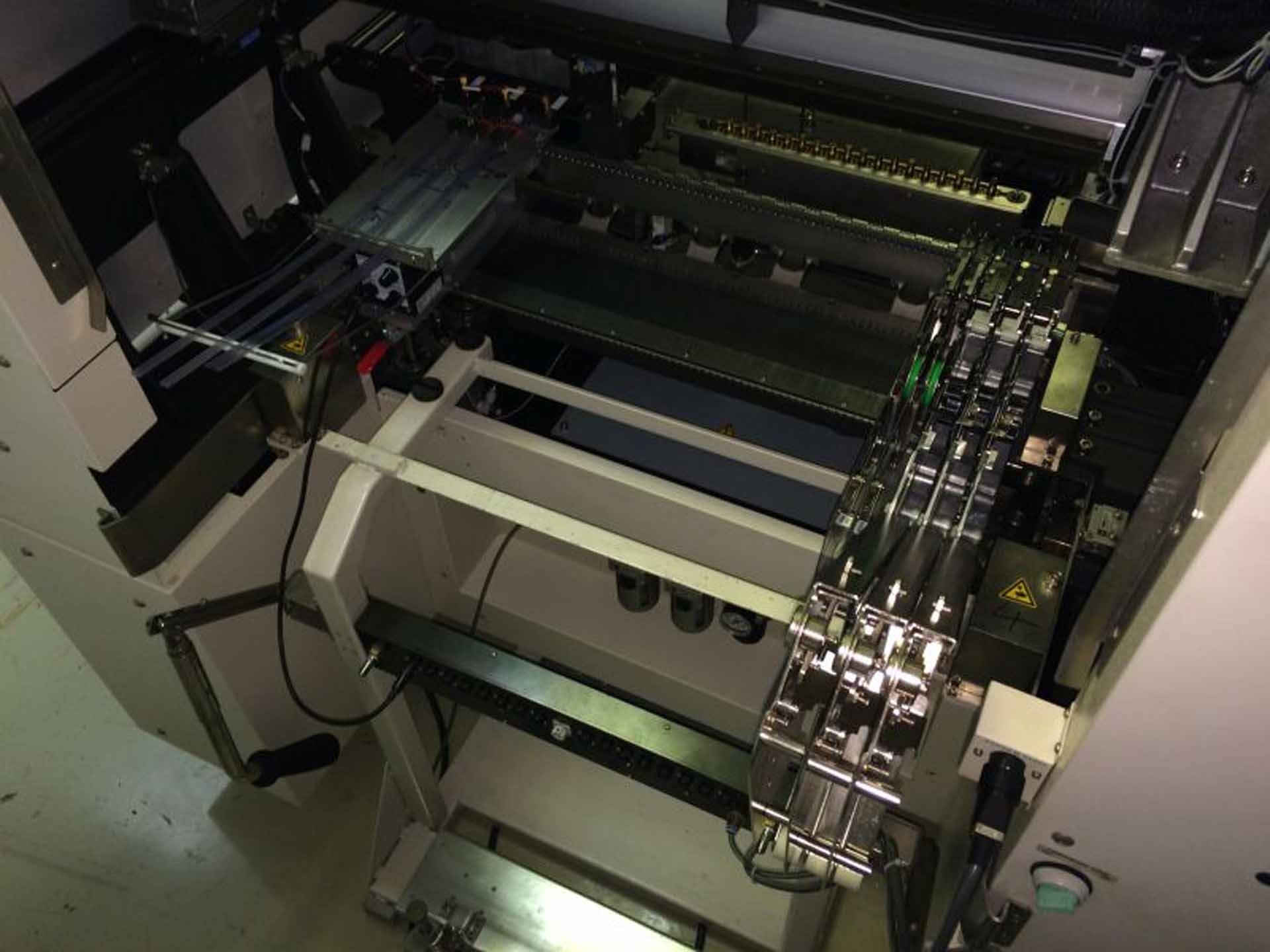

Pick and place machine

Running hours: 12,000

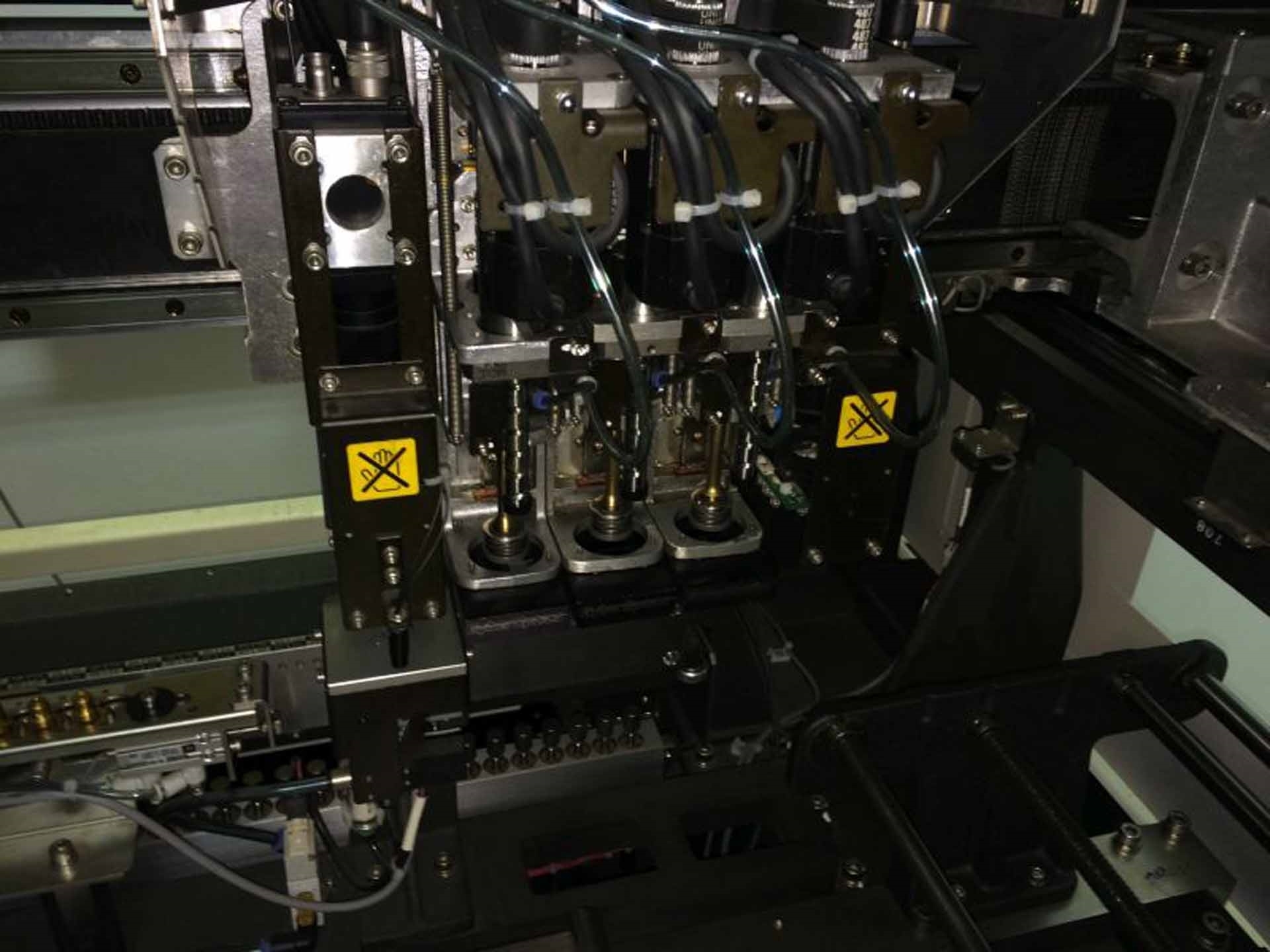

(3) Pipettes

(18) Nozzles:

(3) 101

(3) 102

(3) 103

(3) 104

(2) 105

(2) 106

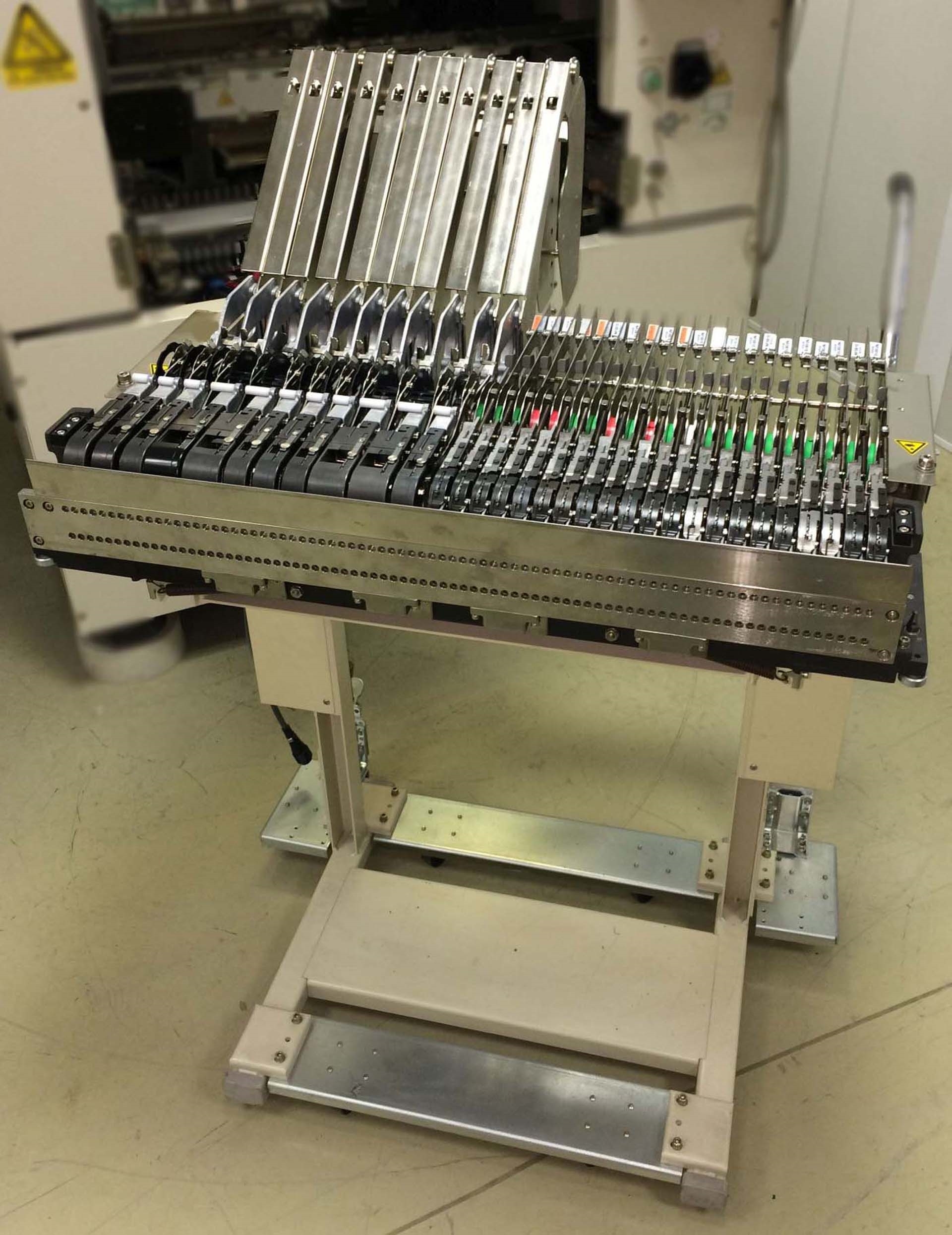

Cart with aligning

(7) Cart without align mark

Vibration feeder

(10) Feeders, 8 mm (NF08)

(50) Feeders, 8 mm (NF81E)

(10) Feeders, 12 mm (FF12FS)

(5) Feeders, 16 mm (FF16FS)

(3) Feeders, 24 mm (FF24FS)

Upgrades:

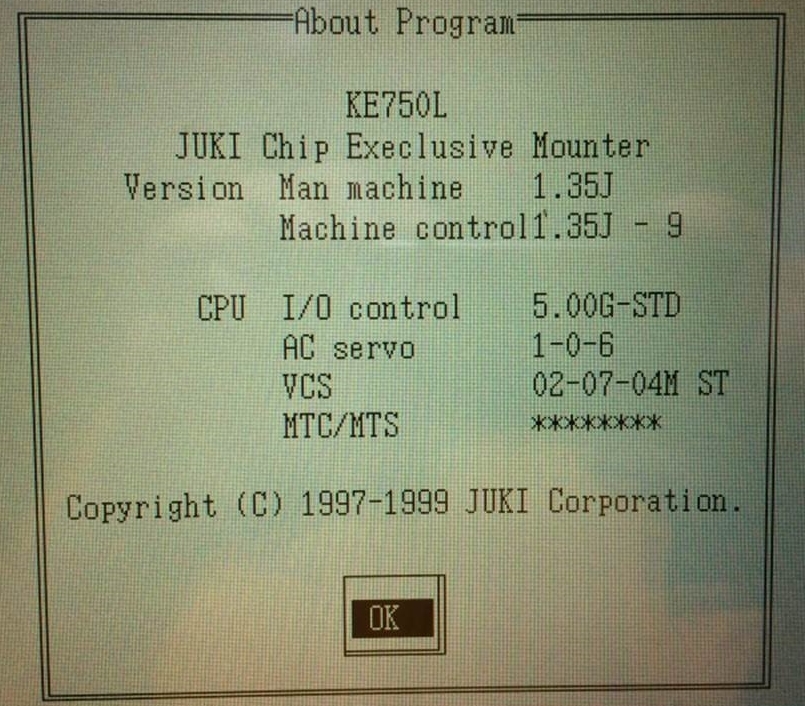

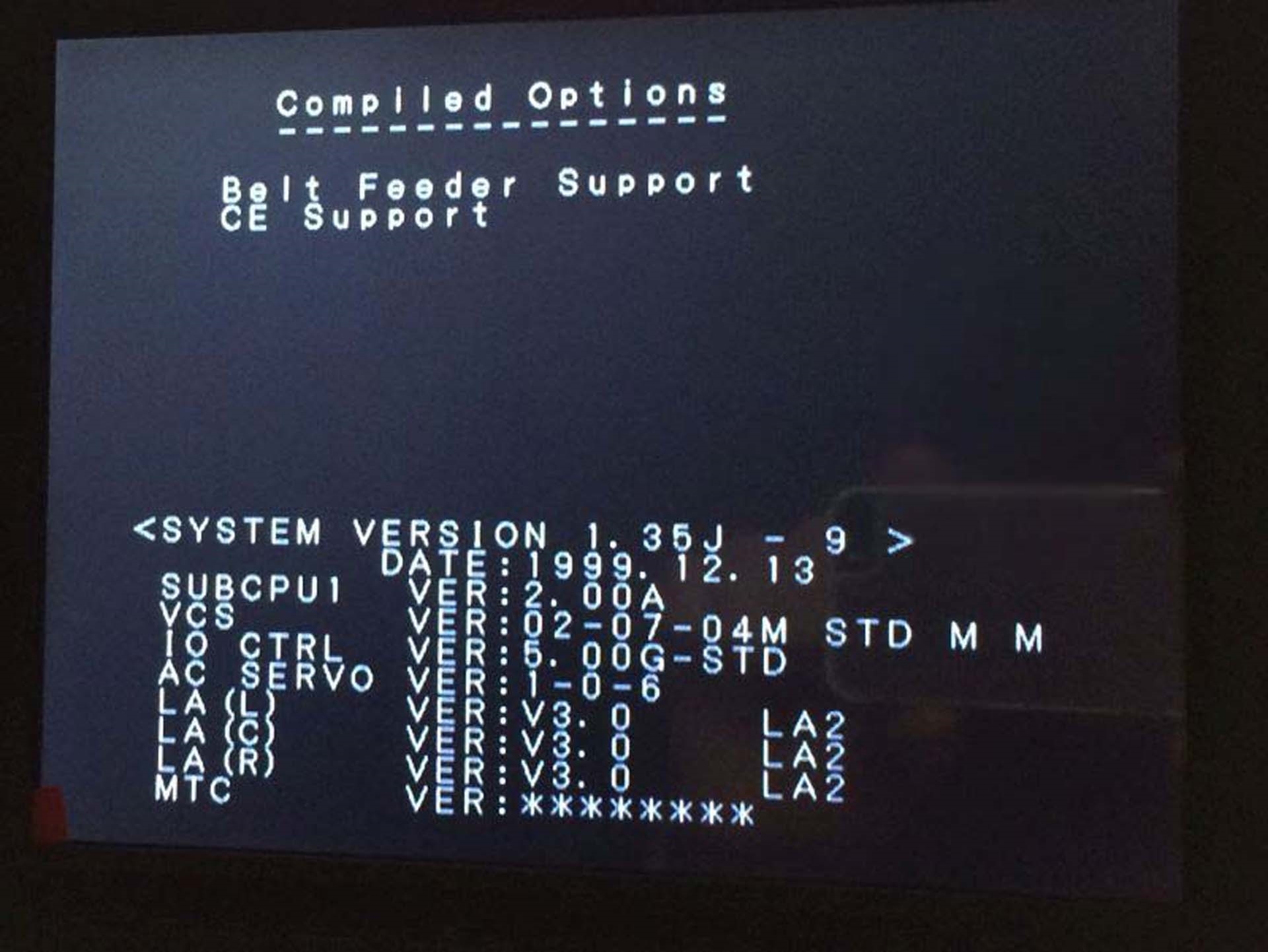

PC

PC LCD With LED backlight

Floppy Disk Drive (FDD), 3.5" replaced by USB unit

Hard Disk Drive (HDD) replaced by SSD

CRT Monitor replaced by 10" LCD

Keyboard

Air filters

Vacuum filters

Spare parts:

(3) Lasers

Motors

Z Drivers

Belts

Boards

PC with LCD

Paper boxes

No BGA camera

Manuals included.

ZEVATECH / JUKI FS 750 PC Board Assembly and Manufacturing Equipment is a high-performance automated assembly system designed to meet the demands of advanced production environments. It utilizes state-of-the-art off-line programming, advanced component placement technology and inspection systems to provide high reliability, high accuracy and fast production. It is ideal for the rapid production of high-volume, small to medium-sized printed circuit boards (PCBs). It uses automatic component placement to remove the need for manual assembly and as such, can greatly reduce production times. The unit supports multiple types of components, including surface mount technology (SMT), pin-in-paste (PiP), and chip-on-board (COB) components. It is fully compatible with various component packages and sizes. This machine is capable of high-speed, high-accuracy component placement - up to 30,000 components per hour, with component accuracy up to ±0.01mm. The advanced features and control systems of JUKI FS 750 ensure reliable and repeatable performance. It is equipped with a four-camera vision tool to allow effective and accurate real-time inspection of PCBs. The integrated self-centering PCB fixture can quickly and accurately locate, load and unload PCBs, enabling quick turnaround production. This asset also boasts a flexible technical configuration that can be tailored to meet specific production requirements. ZEVATECH FS 750 offers efficient and cost-effective production that improves process control and traceability. It is factory-tested and certified for global markets, compatible with product tracking and has a modular construction. The model also features comprehensive accessory options, such as feeder units and alignment marks for component placement accuracy. Its closed-loop motion control equipment ensures fast and accurate component placement every time. Overall, FS 750 PC Board Assembly and Manufacturing System is a reliable, cost-effective, high-performance assembly unit that is ideal for automated production of PCBs. It offers a streamlined production process, increased accuracy and faster turnaround times, ensuring efficient and cost-effective production.

There are no reviews yet