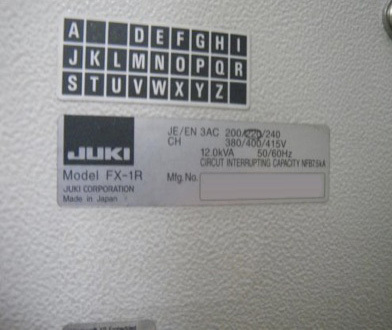

Used ZEVATECH / JUKI FX 1R #9027731 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI FX 1R is an innovative, advanced PCB (Printed Circuit Board) assembly and manufacturing equipment. It combines high-performance electronic design automation (EDA) software, with advanced production automation and modern machine vision technology. All these technologies work together to deliver simple, efficient, and cost-efficient production of complex and sophisticated PCBs. JUKI FX1 R system utilizes a "spiral-shaped conveyor", designed to maximize space efficiency and throughput. Onboard conveyors transport raw material and PCBs around the unit, reducing automated transfer and loading times. ZEVATECH FX-1R also employs high accuracy components including X/Y/Z-axis optical registration, honing feeders, dual head vision aligners, and pneumatic pick-and-place heads. This allows for increased accuracy, better throughput, and higher yield when assembling PCBs. Built-in fixtures and feature recognition capabilities allow ZEVATECH FX 1R to quickly and accurately identify components, accurately placing them in the exact locations on the PCB. Moreover, it also supports more complex shapes, such as SMT parts with angled leads, allowing increased accuracy and better yields. The machine also includes automated optical centering on all the components, allowing for quick, precise placement. FX-1R also has the capability of using "process-dependent force control", when assembling components, making it adaptable for different PCB loadings and components. This allows for a more consistent assembly process and improves the bottom line. Furthermore, JUKI FX 1R tool has built-in cutting-edge production optimization technology, such as lead-free soldering and LED fluxing. This allows for increased throughput and lower cost of production by optimizing various aspects of the assembly process, such as lead-free soldering and LED fluxing. In conclusion, FX 1R is a state-of-the-art assembly and manufacturing asset that utilizes sophisticated EDA, automation, machine vision and production optimization technologies to produce high-quality, high-accuracy PCBs with minimal setup and minimal operator intervention. Its features and advantages make it an invaluable asset to PCB designers and manufacturers.

There are no reviews yet