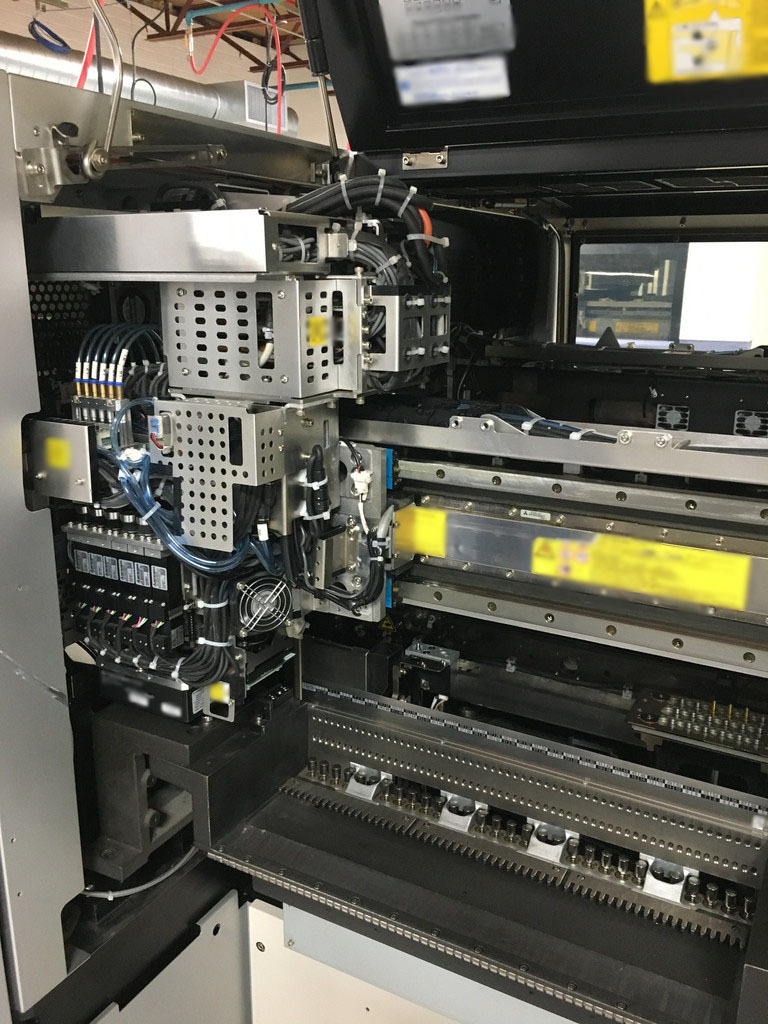

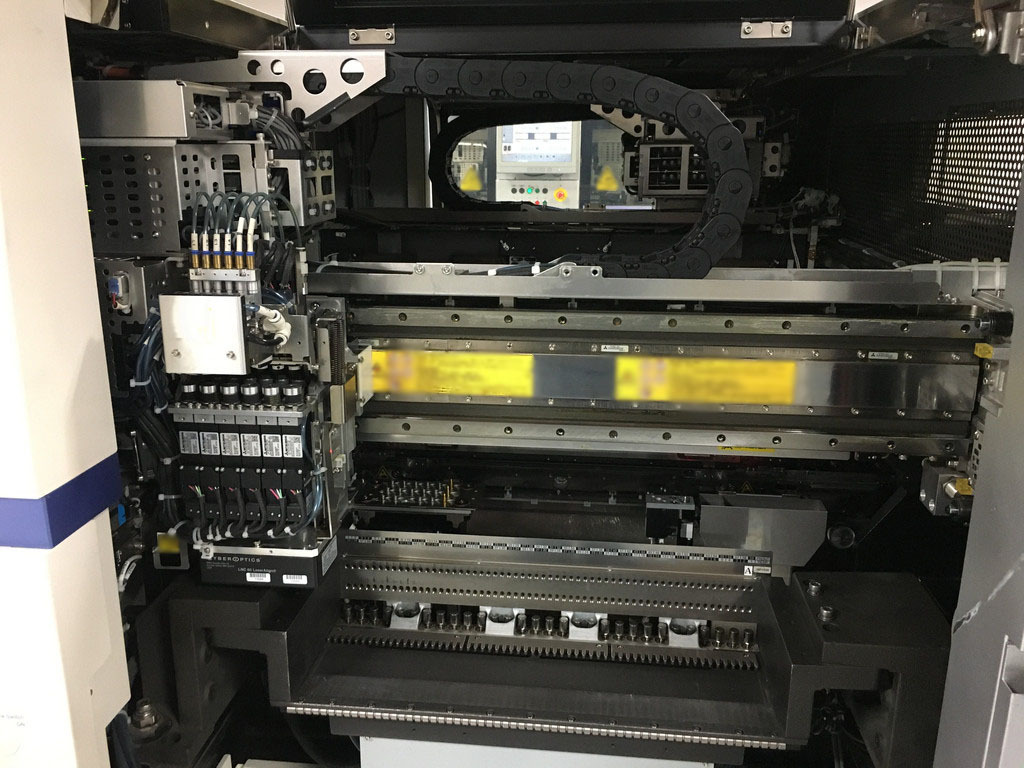

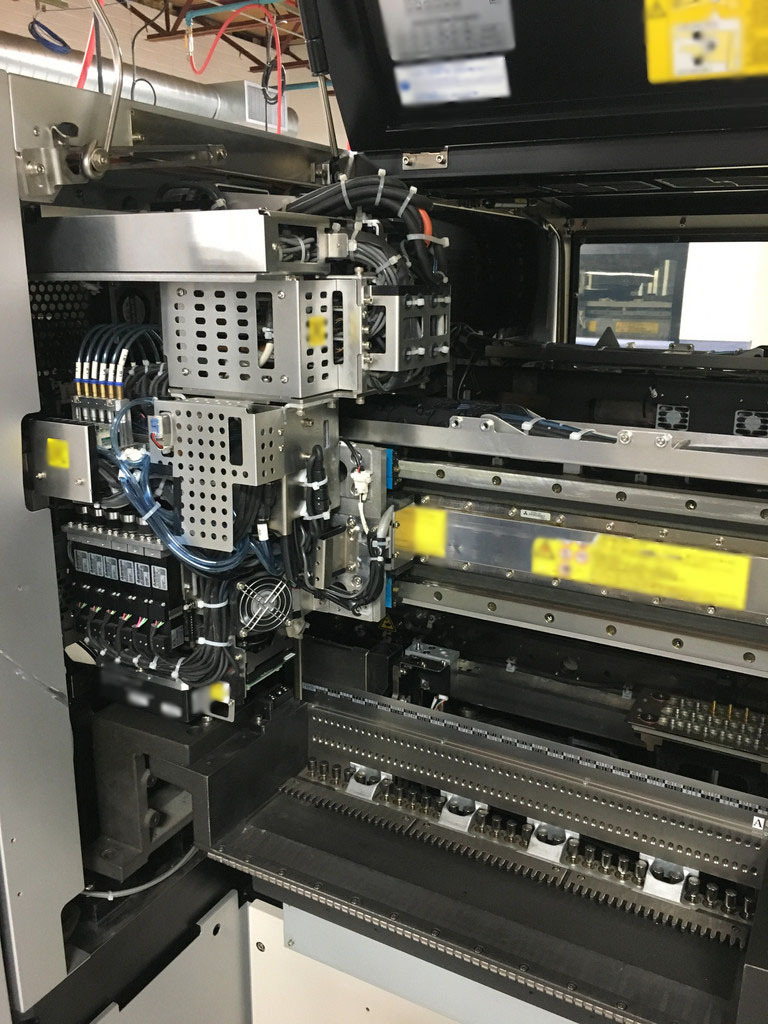

Used ZEVATECH / JUKI FX 3 #9144454 for sale

URL successfully copied!

Tap to zoom

ID: 9144454

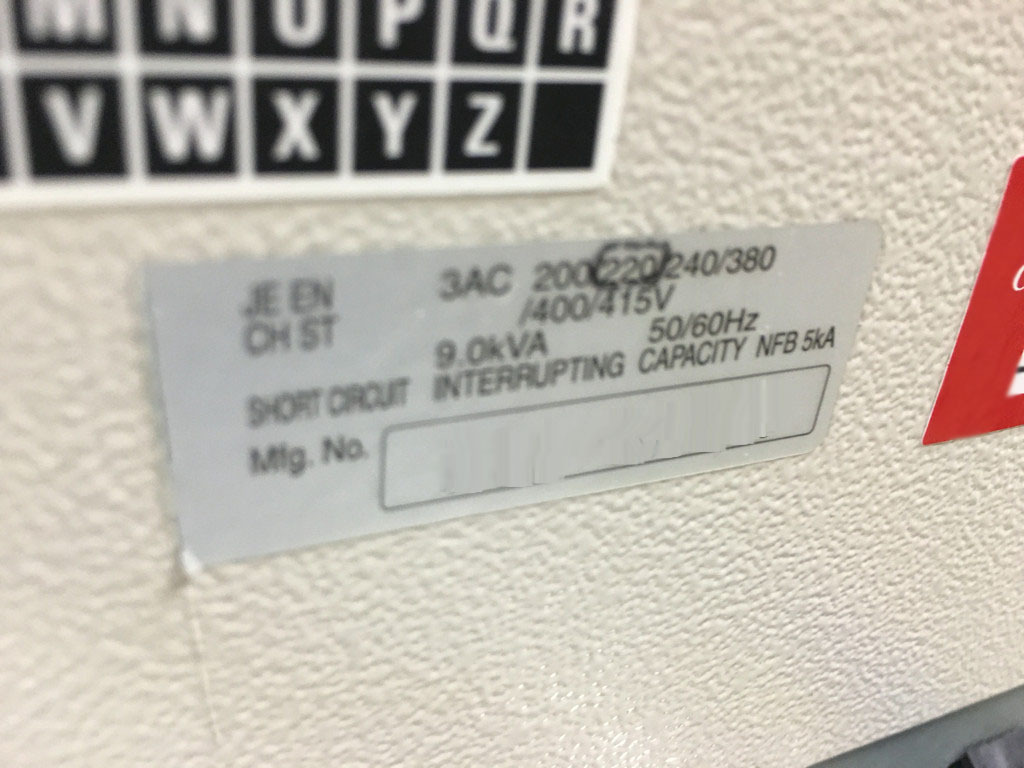

Vintage: 2008

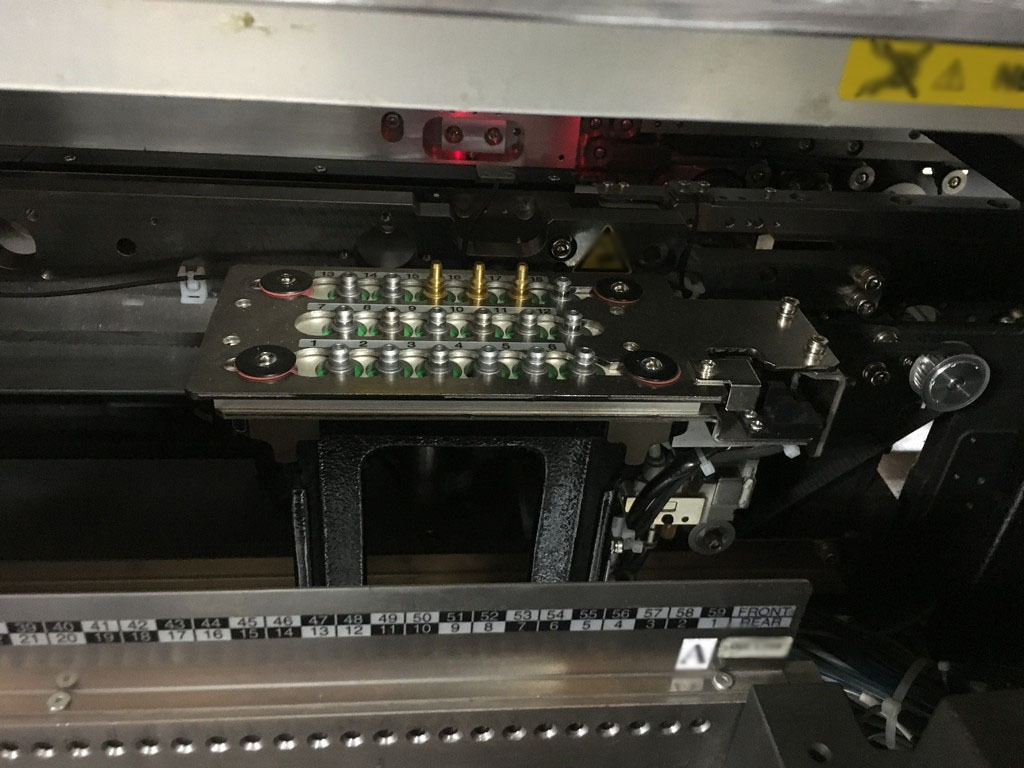

Chip shooter

4 x 6 nozzle heads with LN60 laser

01005 up to 20mm parts

Set of nozzles

(120) 8mm feeders

Fixed feeder banks

2008 vintage.

ZEVATECH / JUKI FX 3 is a PC board assembly and manufacturing equipment designed for surface mount technology (SMT) processes. The system is composed of an assembly line, consisting of several machines, each of which performs a specific step of the production process. JUKI FX3 provides a comprehensive set of features and equipment for SMT production, making it an efficient, flexible, and reliable solution for high-volume production. ZEVATECH FX-3 features an automatic pick and place unit that uses a high precision vision machine to accurately identify and place components. The placement head of the pick and place machine can handle up to 40,000 components per hour, making it suitable for high-volume production runs. The tool is also equipped with advanced features such as an automatic feeder asset with an intelligent part differentiation model, a feeder order optimization equipment, and a software-controlled setup. ZEVATECH / JUKI FX3 also features an advanced placement accuracy with a part placement accuracy of +/- 0.20mm and a vision recognition accuracy of +/- 0.02mm. This allows for precision placement and alignment of components to the desired circuit boards, reducing production errors and ensuring high-quality results. In addition, ZEVATECH FX3 is equipped with a solder paste printing system that uses a printer to deposit a precise amount of solder paste onto the boards. It also features an advanced vision registration unit that can accurately identify components and place them in the correct locations on the board, saving time during the setup process. Finally, FX 3 also includes advanced quality control features such as an integrated process-monitoring machine, a defect-detection tool, and a post-production analysis asset. The process-monitoring model can track the progress of the production process, ensuring consistency and quality. The defect-detection equipment can identify defects in boards and components during production, allowing for immediate correction and reducing scrap. Finally, the post-production analysis system can be used to analyze production data and provide feedback for process improvement and optimization. In conclusion, ZEVATECH FX 3 is a powerful and efficient PC board assembly and manufacturing unit that has proven to be reliable and accurate, making it an ideal choice for high-volume production runs. With its advanced features and quality control capabilities, it is well-equipped to handle demanding SMT production needs.

There are no reviews yet