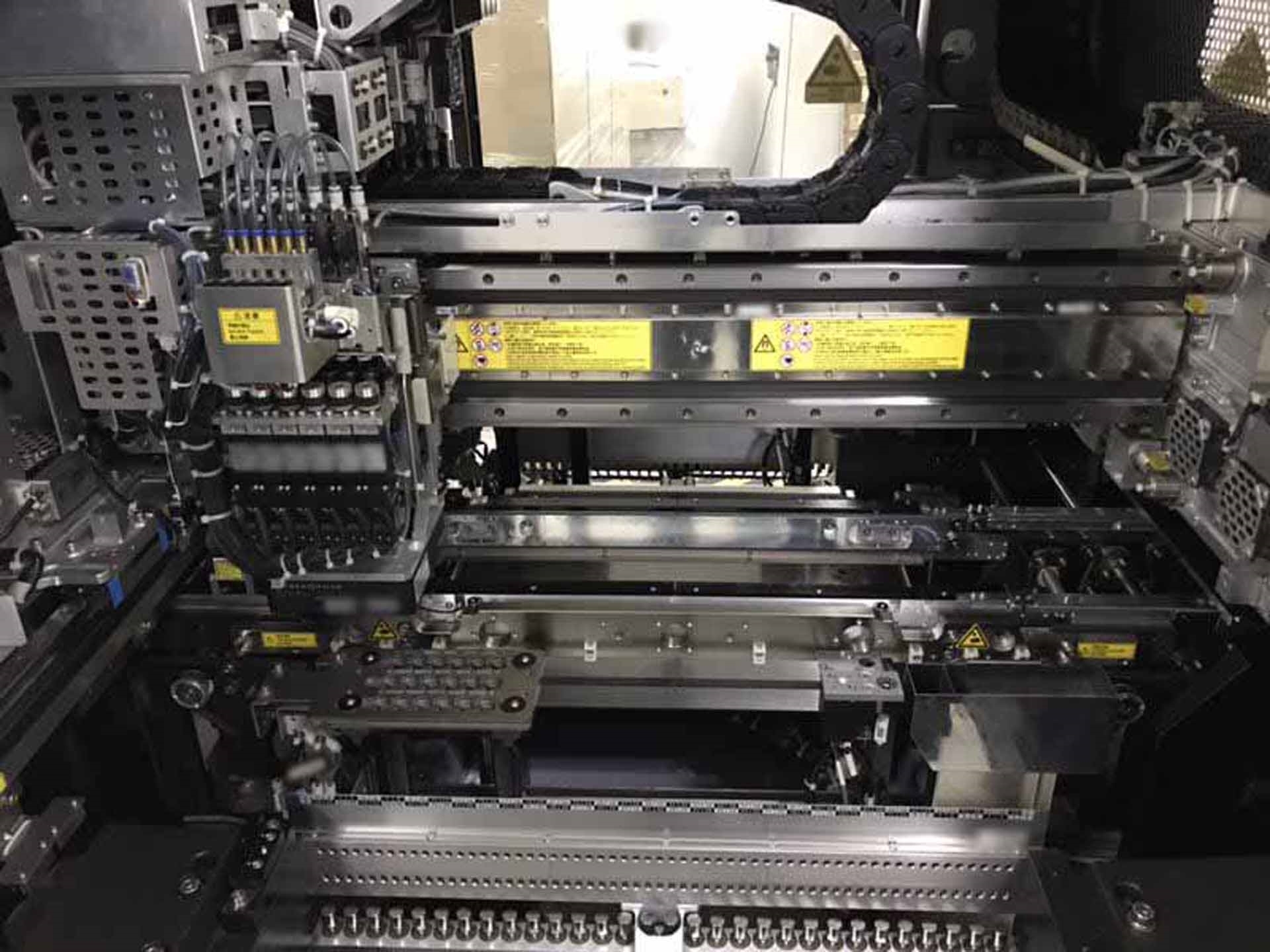

Used ZEVATECH / JUKI FX 3L #9221023 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI FX 3L is a versatile and reliable pc board assembly and manufacturing equipment designed for precision pick and place operations. This all-in-one system combines an array of features that provide high throughput and flexibility, as well as cost-effective operation. The unit is equipped with user-friendly software and features such as non-contact laser centering, optical vision recognition, board warpage detection, and 'Zero Working Space' technology for precision alignment and placement of components. JUKI FX 3L's flexible design allows the user to select from two different placement heads, depending on the components used and the size of the boards being assembled. The 6-head high-speed model offers up to 35,000 placement cycles per hour (cph) whereas the accuracy-oriented 8-head model offers up to 25,000 cph. This cost-effective machine also contains component storage capacities of up to 400x component reels in its offline off-line loader, as well as a component placement accuracy of +/- 0.05mm for metric-sized parts and +/- 0.025mm for imperial-sized parts. The intuitive and user-friendly software of ZEVATECH FX-3L allows for easy program setup, as well as monitoring of the assembly process. The tool includes design files for standard parts, vast libraries of current components, and 3-D component recognition to facilitate fast, accurate assembly. The software also allows operators to establish parameter settings such as index speed and vision recognition parameters, which can be adjusted for optimized part placement. Additionally, the integrated high-speed vision camera asset is capable of analyzing and recognizing a variety of components in preparation for placement. FX-3L assembly model includes an array of other features which help maximize performance and efficiency. Advanced nozzle cleaning prevents loss of parts from adhesive build up, while 'Nobekashi' technology increases pick-up speed for large components. The equipment is also equipped with an offline programming feature which allows users to quickly program parts without waiting for assembly cycles to complete, as well as a built-in board cleaning system for removing flux residues. In conclusion, FX 3L pc board assembly and manufacturing unit is designed for quick, accurate, and cost-effective operations. It combines user-friendly software, adjustable parameters, and advanced features to provide increased throughput and flexibility for a variety of components.

There are no reviews yet