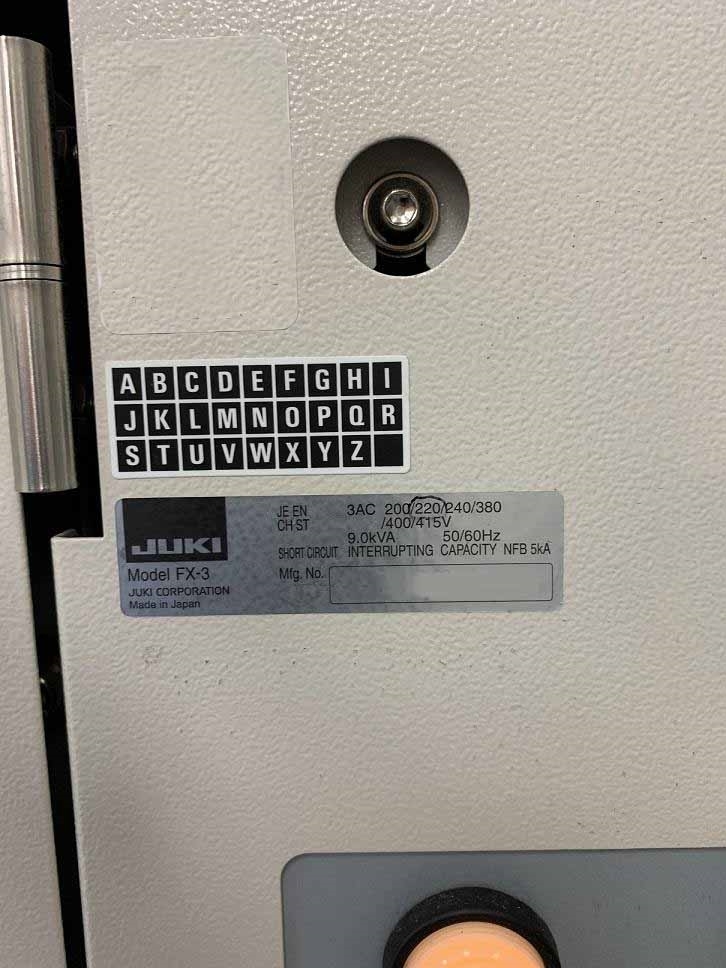

Used ZEVATECH / JUKI FX 3L #9257574 for sale

URL successfully copied!

Tap to zoom

ID: 9257574

Vintage: 2008

Pick and place machine

CPH: 60,000

(4) Heads

(6) Nozzles

(4) Feeder trolleys

Square parts: 01005 - 33.5 mm

Auto pick position teaching

Height measurement system

Maximum board size: 14" x 16"

Feeder inputs: 120 8 mm

Interface for mechanical and electronic feeders

Mechanical feeder trolleys

2008 vintage.

The ZEVATEKZEVATECH / JUKI FX 3L PC Board Assembly and Manufacturing Equipment is a high-speed, high-precision, low-cost SMT production solution ideal for a variety of production quantities. The system's fully-automated operation provides enhanced production process capabilities compared to other manual technologies. JUKI FX 3L unit includes a host of features that make SMT production simple and efficient. The machine is composed of several key elements, such as an integrated tool controller, conveyor, and head station. The asset controller centralizes all motoristic, application, PC board tracking, and operational data/commands. The conveyor is designed for the customer's process, providing a reliable platform for components to move along the entire line. The head station is designed for loading components in quick fashion, operated by two 14-inch servo driven pick-and-place heads. ZEVATECH FX-3L model was designed with flexibility and configurability in mind. Its conveyor equipment can be configured with one of three widths, 15", 18", and 24", and overall length from 11" to 80". The systems can also be configured for multi-zone operation with various board sizes and shapes, component types, and placement, assembly, and alignment needs. ZEVATECH / JUKI FX-3L system is loaded and unloaded with ease, thanks to its large component capacity hopper. The hopper allows for the storage of components with different types, heights, and sizes, along with a simple switching of the types and heights of the components. The component recognition also allows operators to easily and quickly differentiate between components, saving time and providing a higher level of accuracy. The unit is highly reliable and consists of several safety features, such as a low-pressure machine, alignment limit switches, air regeneration, AC and DC voltage inputs, and AC sockets and plugs. The tool also includes several sensors to detect component position, as well as an error message display. The entire ZEVATECH FX 3L asset is designed and manufactured under stringent standards, ensuring consistent product quality and performance. The model's modular design allows easy upgrade paths and the ability to incorporate new technology or changes with ease. Overall, FX 3L PC Board Assembly and Manufacturing Equipment is an efficient, cost-effective, and reliable solution that is ideal for a variety of production quantities. Its flexibility and configurability, along with its redundant safety features, make it a powerful tool for any production line.

There are no reviews yet