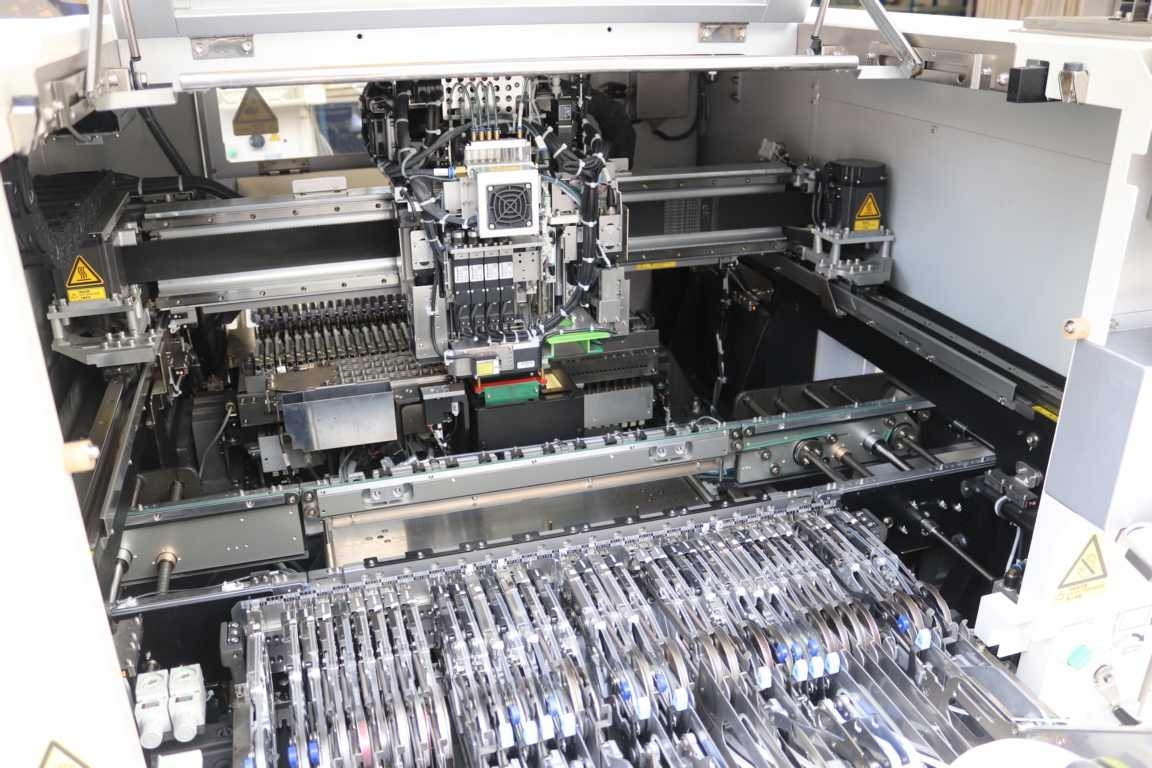

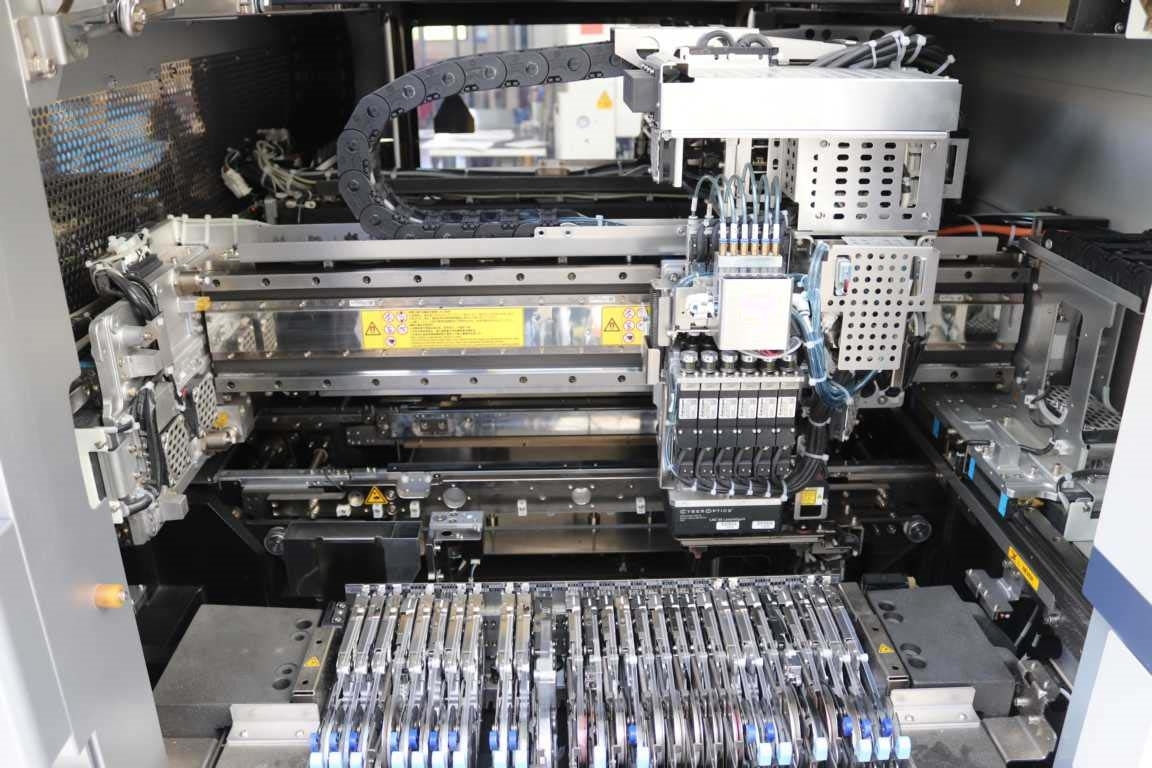

Used ZEVATECH / JUKI FX 3L #9289071 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI FX 3L is a complete, high-performance, continuous, pc board assembly and manufacturing equipment for medium to high-volume productions. It features fully automated, inline processing capabilities, with 3-level feeder setup. The system is designed for efficient handling of both leaded and lead-free components, and is flexible enough to accommodate a variety of smt component types. JUKI FX 3L features a total of 12 placement heads, with 10 high-speed modules and 2 dedicated odd-form placers. The unit can attain placement speeds up to 15,000 components per hour, with an accuracy of up to 0.020 mm and is capable of handling components with 0201 chip and 4.2mm pitch packages. A dual-track pickup nozzle machine is available for components in multi-line packages, and it also has an output-end vision tool for full recognition of component placement position and solder joint quality, allowing for high-precision placements. In addition, ZEVATECH FX-3L is equipped with a built-in cleaning asset for components that may have been exposed to contamination through assembly or testing processes. It features an aircooled vacuum cleaner to reduce environmental impact, a hot-air cleaning module to remove surface contamination, a solvent cleaning station, and an integrated vacuum cleaner to reduce the risk of static discharge and other damage to the components during cleaning. The model's fully-automated intelligent loading and unloading equipment eliminates wasted operator time, and allows optimum utilization of the production line. The user-friendly GUI allows for quick and easy product changeover and setup. Additionally, the system is equipped with an acoustic alarm to alert operators of unsafe operating conditions, such as nozzle entrapment. Overall, ZEVATECH / JUKI FX-3L provides a complete, high-performance, pc board assembly and manufacturing solution for medium to high-volume productions. Its automated and precise processes reduce time and increase production efficiency, while its safety features ensure a safe working environment. Furthermore, its built-in cleaning unit helps eliminate component contamination that may prevent successful assembly processes.

There are no reviews yet