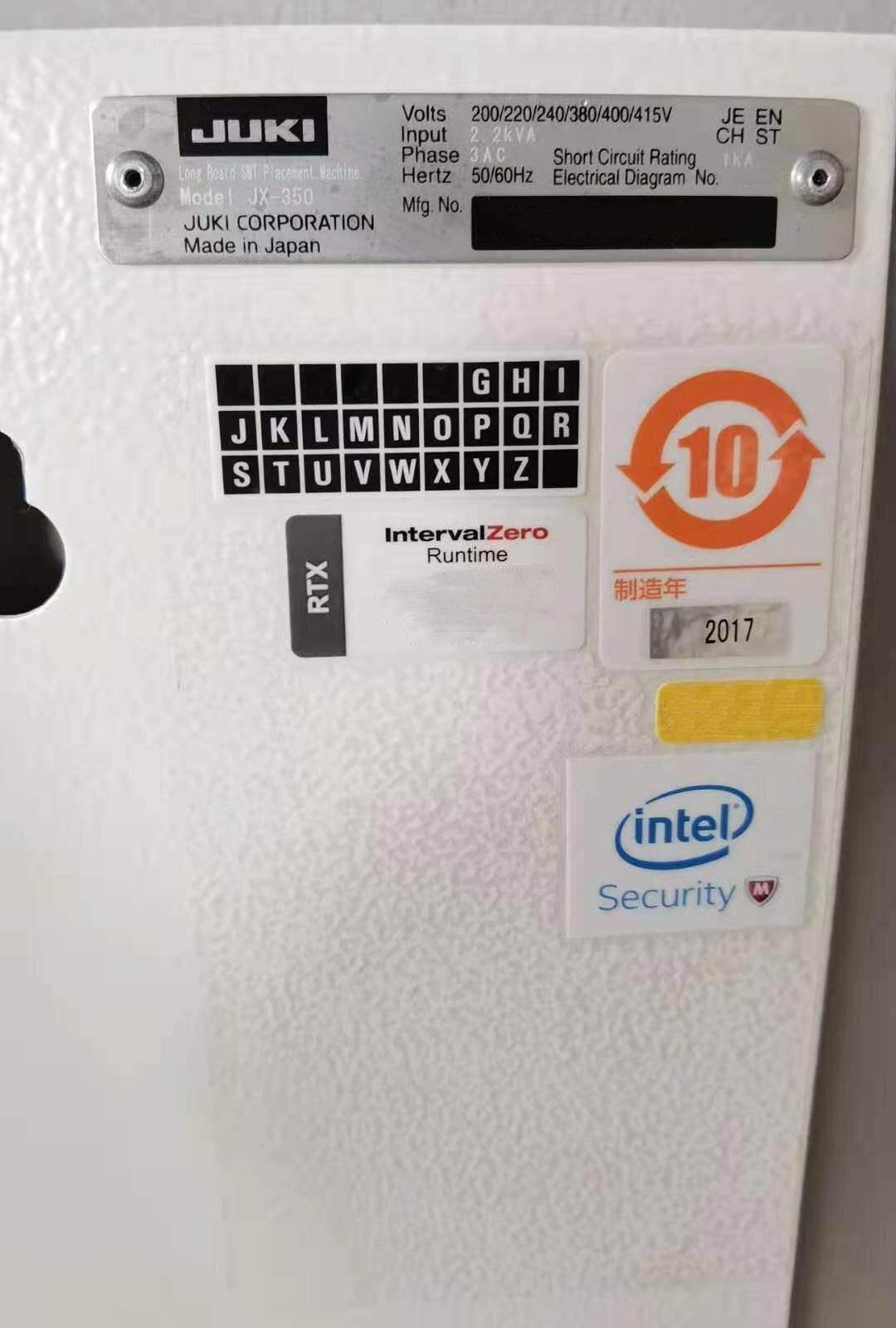

Used ZEVATECH / JUKI JX-350 #9386741 for sale

URL successfully copied!

Tap to zoom

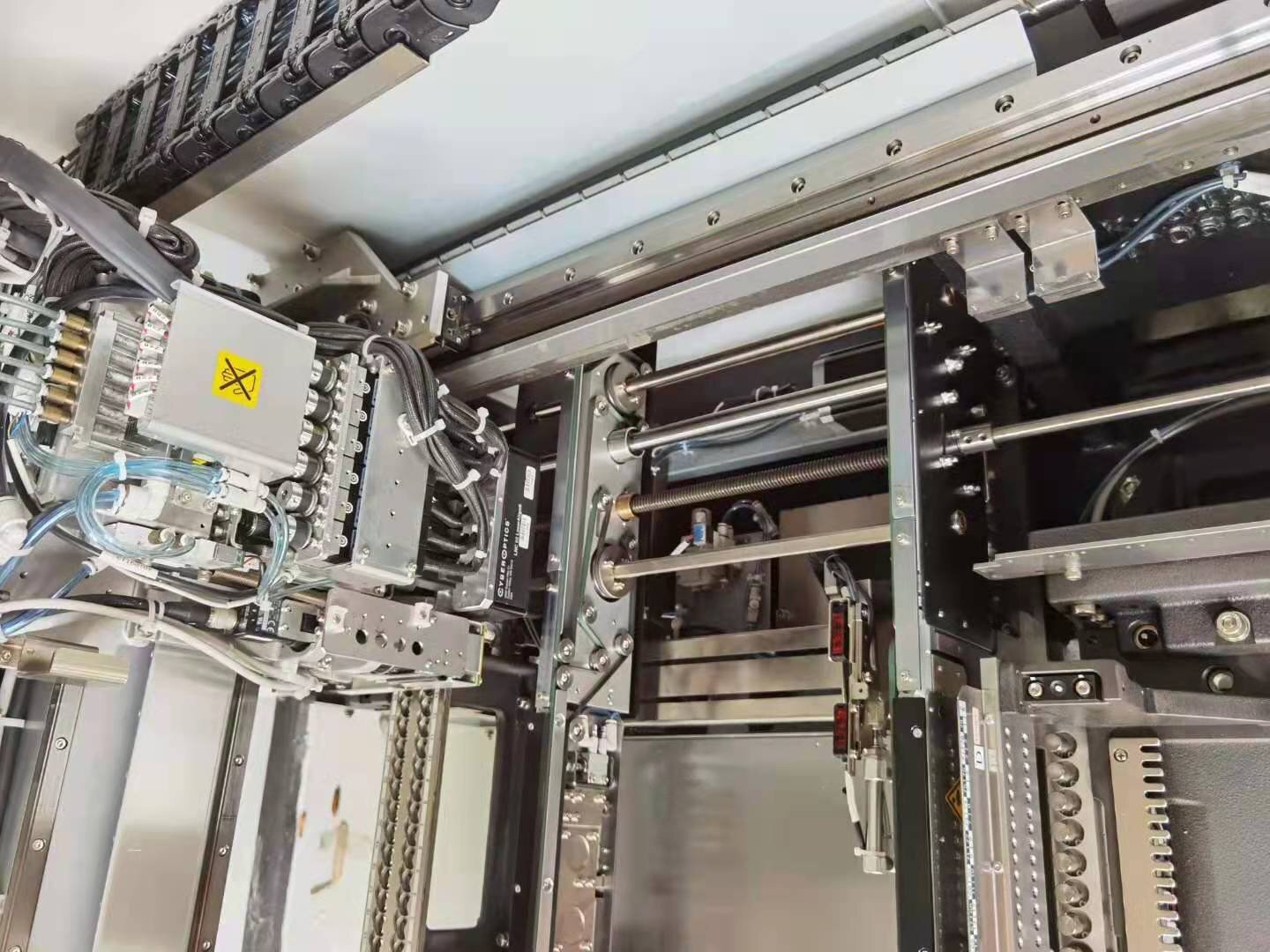

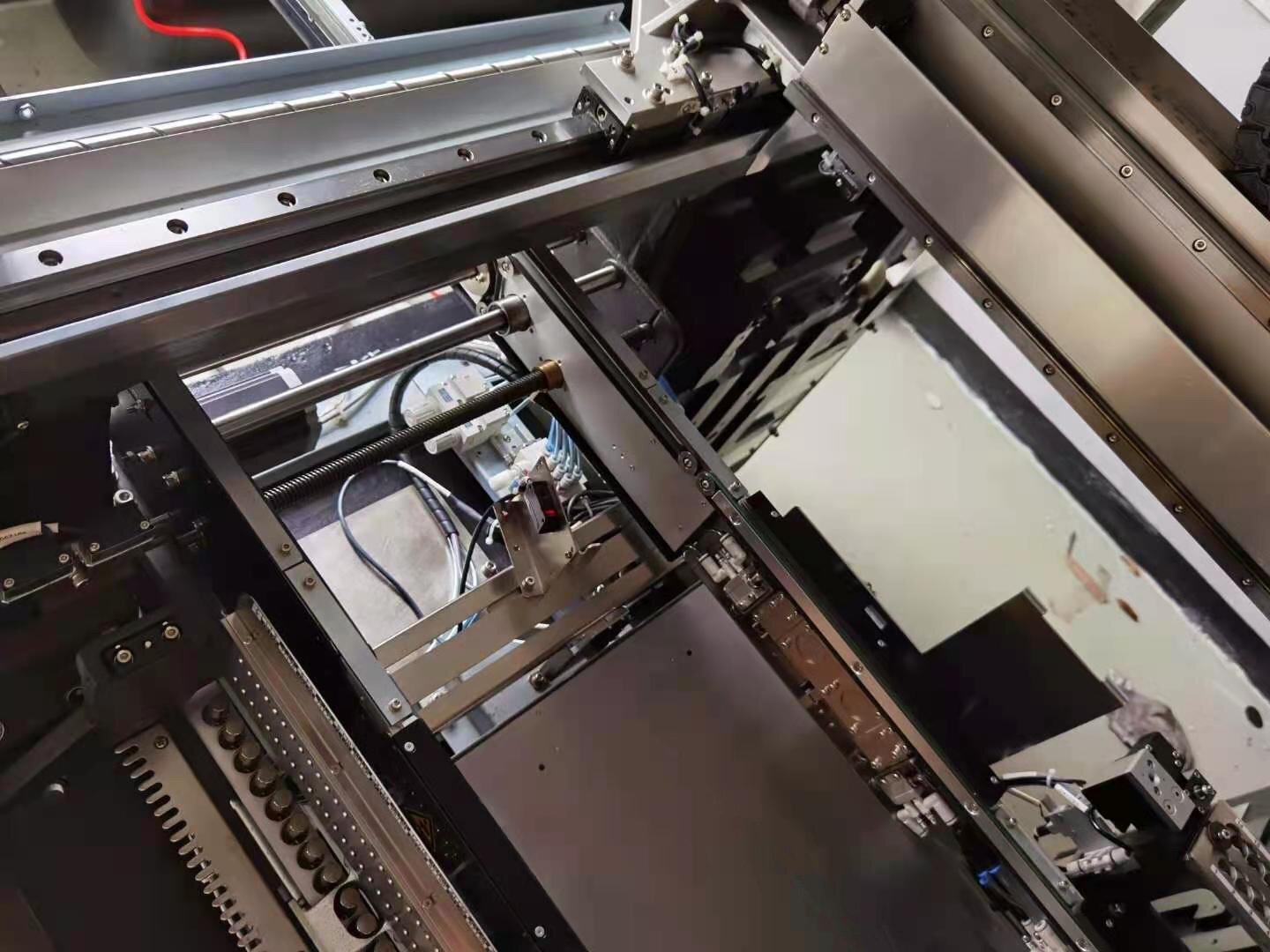

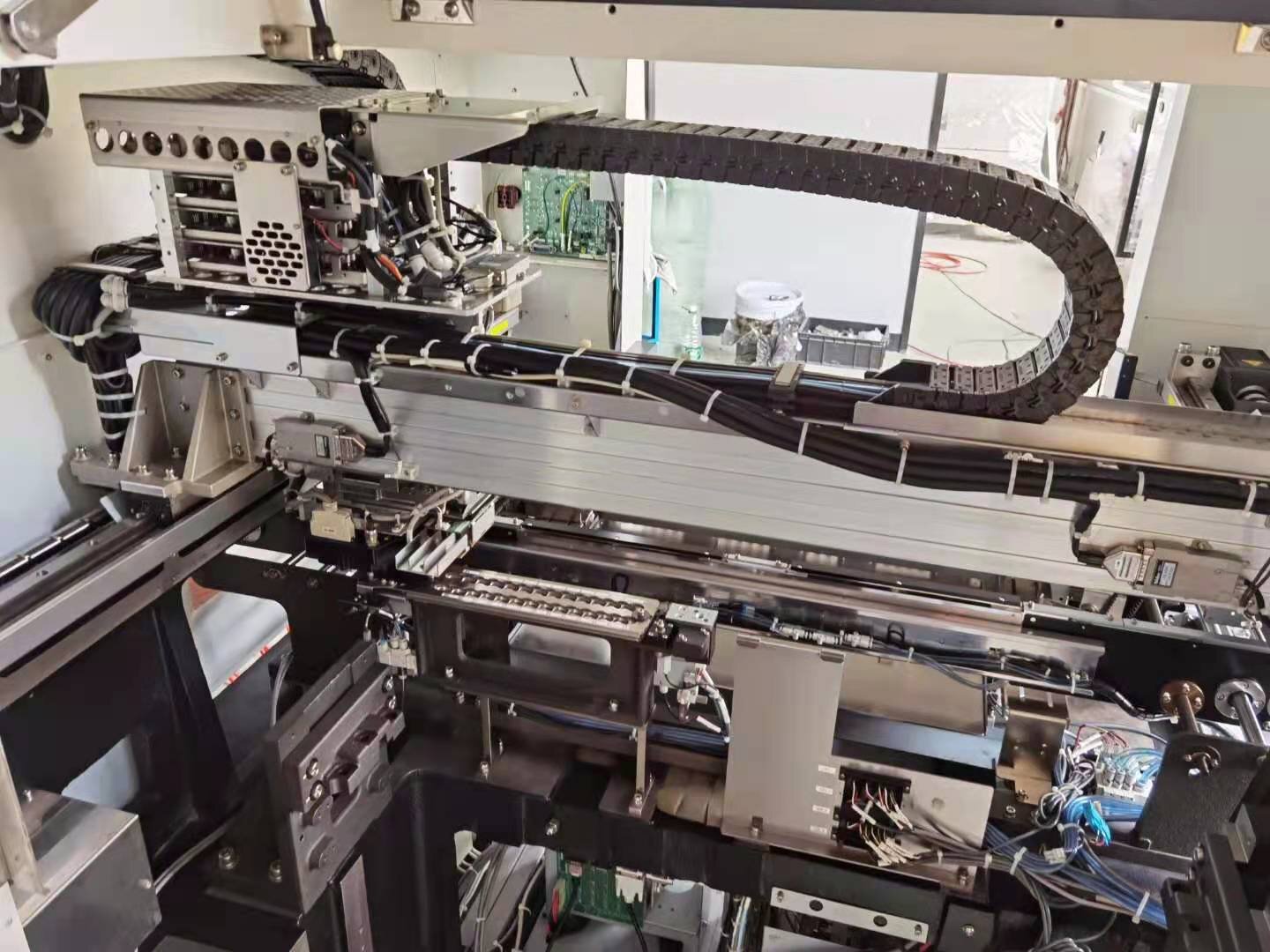

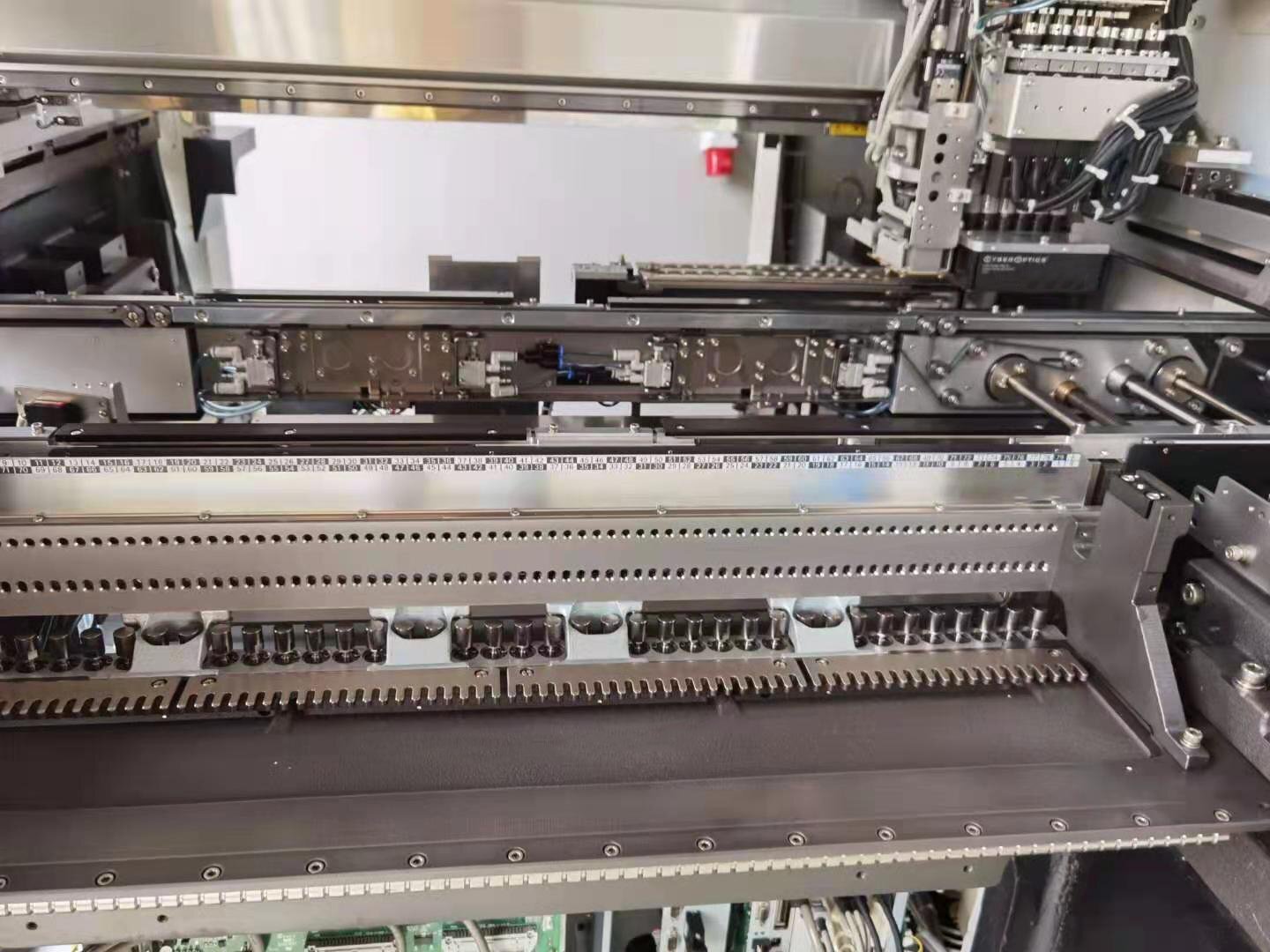

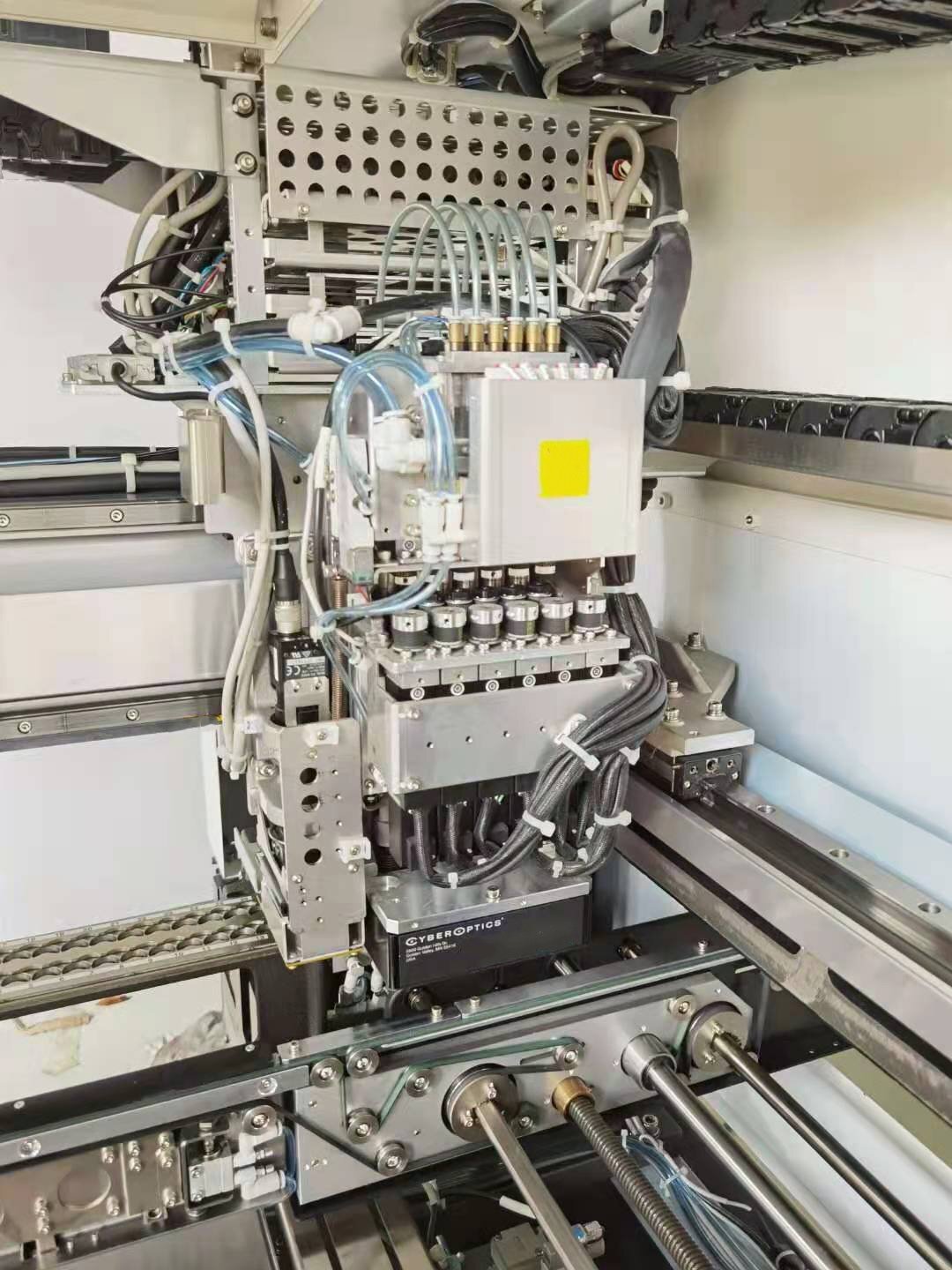

ZEVATECH / JUKI JX-350 is a PC board assembly and manufacturing equipment that provides a high level of accuracy and speed for prototyping and mass production applications. It is suitable for low-medium volume assembly of SMD (surface-mount device) components on PCBs (printed circuit boards). The system comes in a space-saving, small-scale, single-frame design. JUKI JX-350 integrates a vision-based component placement unit as one of its features, allowing for highly accurate positioning and delivery of SMD components with a minimum cycle time of 4-5 seconds per component. The machine also includes a program-controlled splitting device to allow parts to be referenced by the vision-based component placement tool before pick-and-place. This device can be adjusted depending on the size and type of component being used. The integrated vision asset allows for precise vision alignment of parts prior to placement, increasing the accuracy of component placement by up to 10%. Furthermore, the vision model can identify components and PCBs automatically, drastically reducing the need for manual programming. To ensure high yields, the equipment employs a multi-zone pre-heating system that ensures uniform preheating of the PCB prior to assembly. The unit also features adjustable nozzle spacers which ensure optimal pressure application when dispensing flux or adhesive. Additionally, it includes several sensors to detect component yields and monitor temperature levels. Additionally, the machine is outfitted with a dual-head SMD nozzle head which provides a fast and flexible component placement. ZEVATECH JX350 offers a wide range of advantaged over its predecessors, such as a CCD camera for defect mobile ability and a speedy 30 second CCD image processing speed. Additionally, it offers a 4-head nozzle tool for use in lead forming and allows for up to 6 simultaneous placement axes. It is also equipped with a dual tool feeder that is capable of handling both reel-type and tray-type product feeding. To ensure high operation speeds, the asset includes a high-speed motor drive and a rotary table with a maximum speed of 500mm/s for the component mounting line. To ensure that the model meets any customer's desired part accuracy and productivity, JX-350 can be adjusted to perform operations with several different machine settings. This include the ability to process 0402 components, adjust the placement strategy for components with different shapes, and modify the vision equipment calibration methods. JX350 is a top-of-the-line PC board assembly and manufacturing system that makes it easy to achieve accurate, high-speed prototyping or mass production.

There are no reviews yet