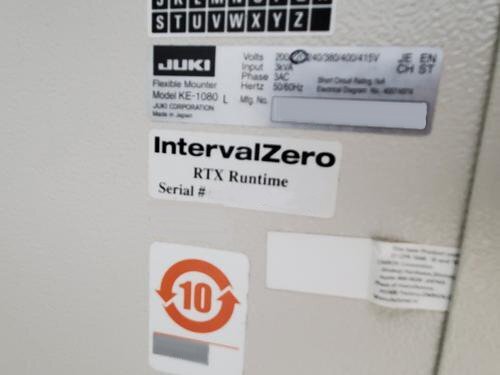

Used ZEVATECH / JUKI KE 1080L #9225908 for sale

URL successfully copied!

Tap to zoom

ID: 9225908

Vintage: 2011

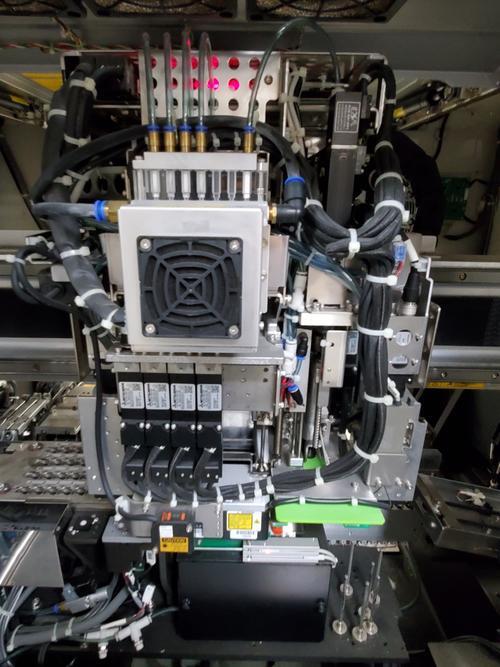

Pick and place machine

Side mount single magazine TR6 tray feeder

Fixed feeder bank front and rear

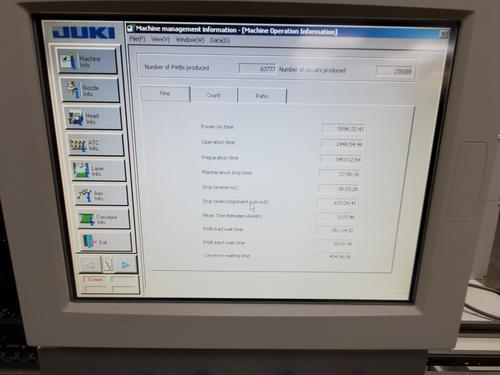

Running hour: 25000 Hrs

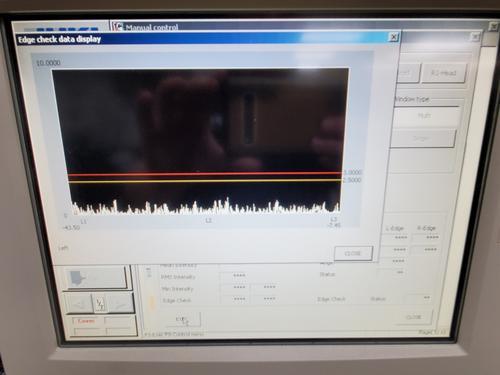

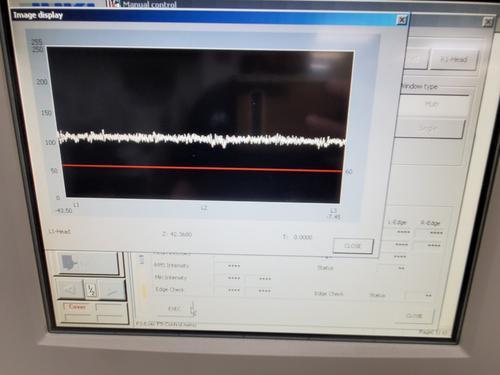

HMS Sensor

ULC Camera for micro BGA

(50) Assorted feeders included

2011 vintage.

ZEVATECH / JUKI KE 1080L is a precision PC board assembly and manufacturing equipment developed by JUKI, in cooperation with ZEVATECH. It is an advanced SMT (Surface Mount Technology) production system, designed to deliver precise, consistent, and high-quality PCB assemblies with a minimum of set-up time. JUKI KE 1080L offers superior and reliable performance with a 12-zone convection reflow oven, which is equipped with a multi-profile precision control. The unit also has a powerful memory of up to 1000 PCB pattern data. The wide breadth of components supported includes 0201 chip components, ultra-fine pitch components, fine-pitch lead-less components, and Flip-Chip BGAs. ZEVATECH KE 1080L's high-accuracy component placement is achievable through a multi-point head vision alignment machine, and a component registration-mark inspection tool. It is equipped with a high-speed vision board inspection asset which enables the model to accurately inspect both the soldering joints and component irregularity and misplacement. KE 1080L is compatible with a wide range of printed circuit boards, ranging from those used in consumer electronic products to non-leaded components, for up to 2.54 mm pitch, down to 0.2 mm & up to 28 mm, 0.4 mm pitch fine pitch components. It also has an easy-to-use programming operation; an advanced and powerful monitor visual management equipment; a powerful communication interface and software support; and an advanced free-wheeling function, which enables flexible product handling and production steadiness. ZEVATECH / JUKI KE 1080L features a multiple-pattern recognition system, so that multiple PCB patterns can be recognized at once. Its fast data exchange capability greatly shorterides downtime for changing PCB patterns. The unit is also equipped with an advanced monitoring machine that monitors and reports any errors that occur during production as well as tool problems. Overall, JUKI KE 1080L is a powerful, precision, versatile PC board assembly and manufacturing asset that is capable of delivering rapid and high-quality PCB assemblies with extremely fast set-up time and minimal maintenance. Its high-accuracy component placement enables users of all levels to quickly assemble and manufacture PCBs with maximum accuracy and consistency.

There are no reviews yet