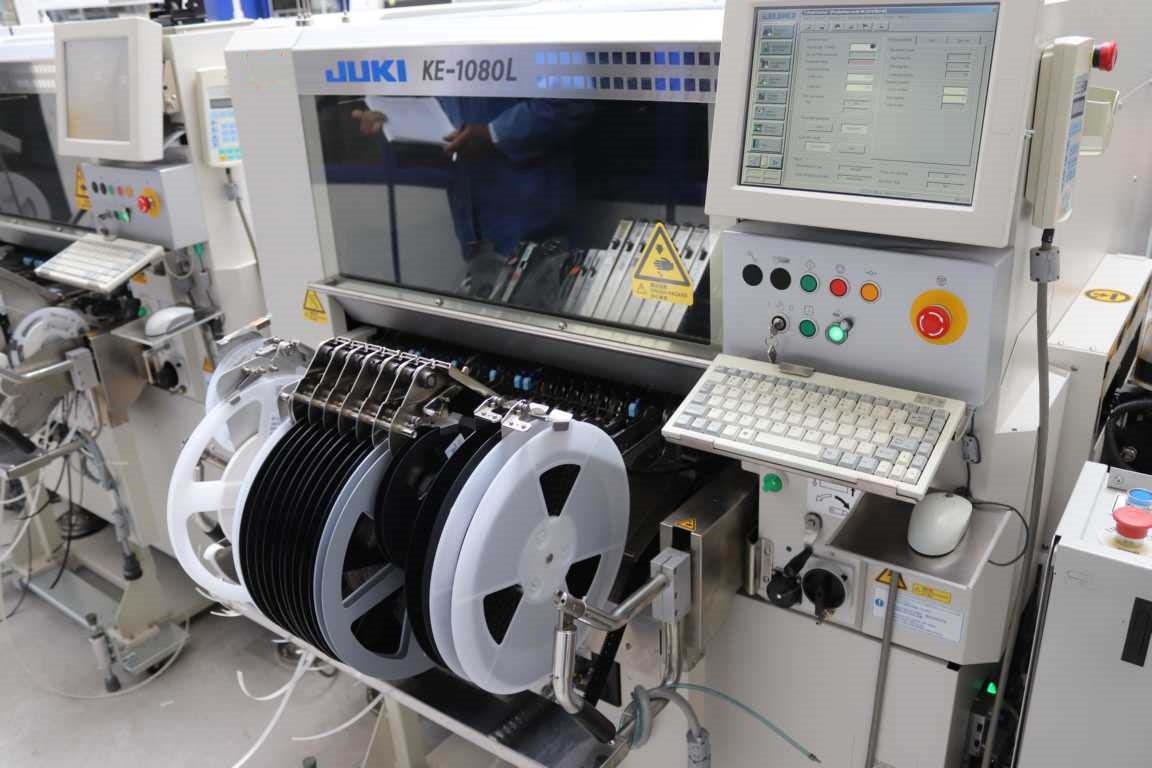

Used ZEVATECH / JUKI KE 1080L #9289065 for sale

URL successfully copied!

Tap to zoom

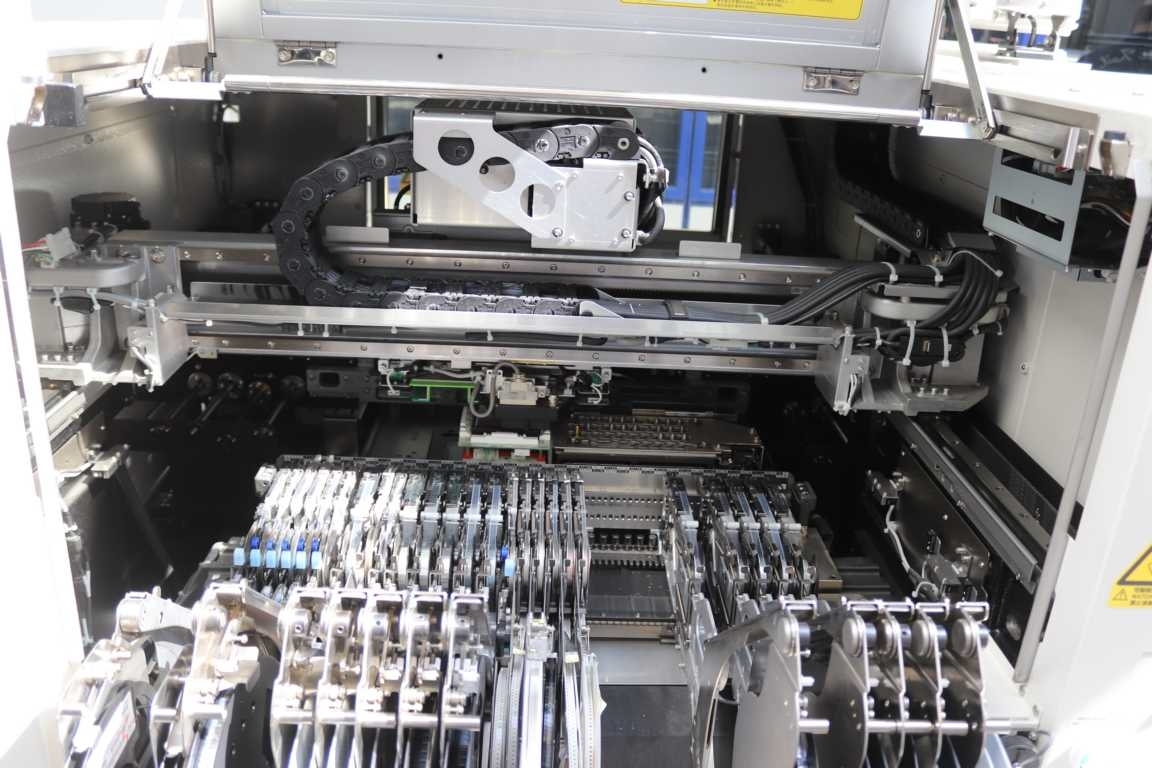

ZEVATECH / JUKI KE 1080L is a high-end, fully automated, PC Board Assembly and Manufacturing equipment. It is designed to provide high quality, efficient production of bare boards, populated boards, and complete system assembly. JUKI KE 1080L relies on three main components for an efficient production line. The first component is a high-speed, precision pick-and-place machine. The pick-and-place machine is programmable with JUKI CNC software. It uses cameras to align components accurately to the printed circuit board. The machine also has an integrated vision unit, which can detect the correct position of components and pick them up accordingly. Accuracy for the machine is within ± 0.025mm. The second major component of the machine is a reflow oven. The oven features precision temperature mapping that ensures each component is correctly heated and cooled for accurate soldering. In addition, the oven includes a board flipping station that facilitates efficient loading and unloading of the oven. The tool is completed with a top of the line board inspection asset. The model is designed to detect a variety of defects such as component misplacement, solder bridges, and incorrect pin connection. By performing defect detection while the parts are still on the board, the machine can be used to quickly spot defects and can be used to assess the quality of the boards. ZEVATECH KE 1080L is an efficient, consistent, and reliable PC Board Assembly and Manufacturing equipment designed to meet the needs of a variety of electronic manufacturers. Its integrated pick-and-place and reflow oven components can be used to quickly process printed circuit boards and ensure an optimal quality level. The system also includes a board inspection unit to detect any errors that may occur during the assembly process, ensuring a final product that stands up to customer expectations.

There are no reviews yet