Used ZEVATECH / JUKI KE 2010L #293633092 for sale

URL successfully copied!

Tap to zoom

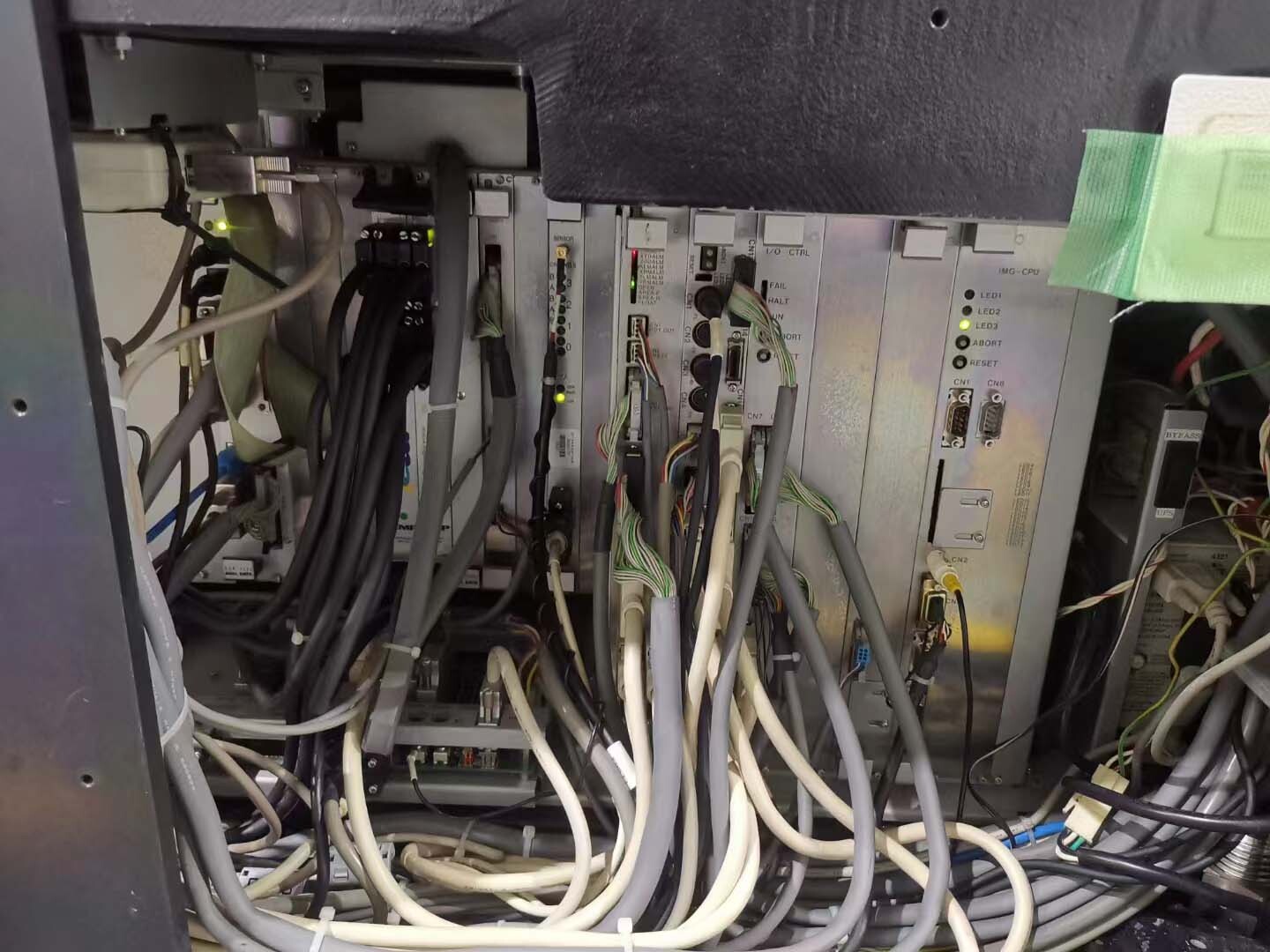

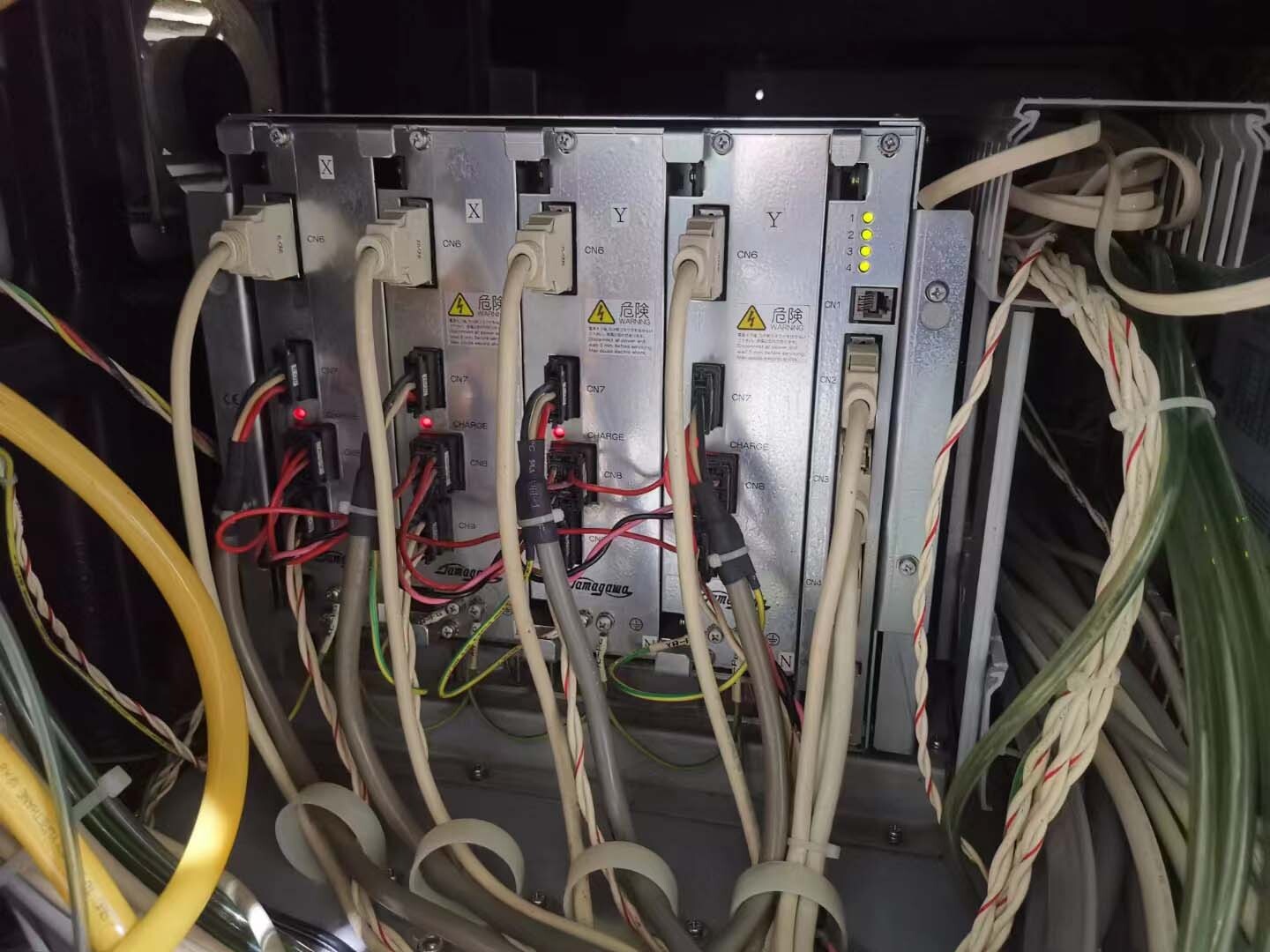

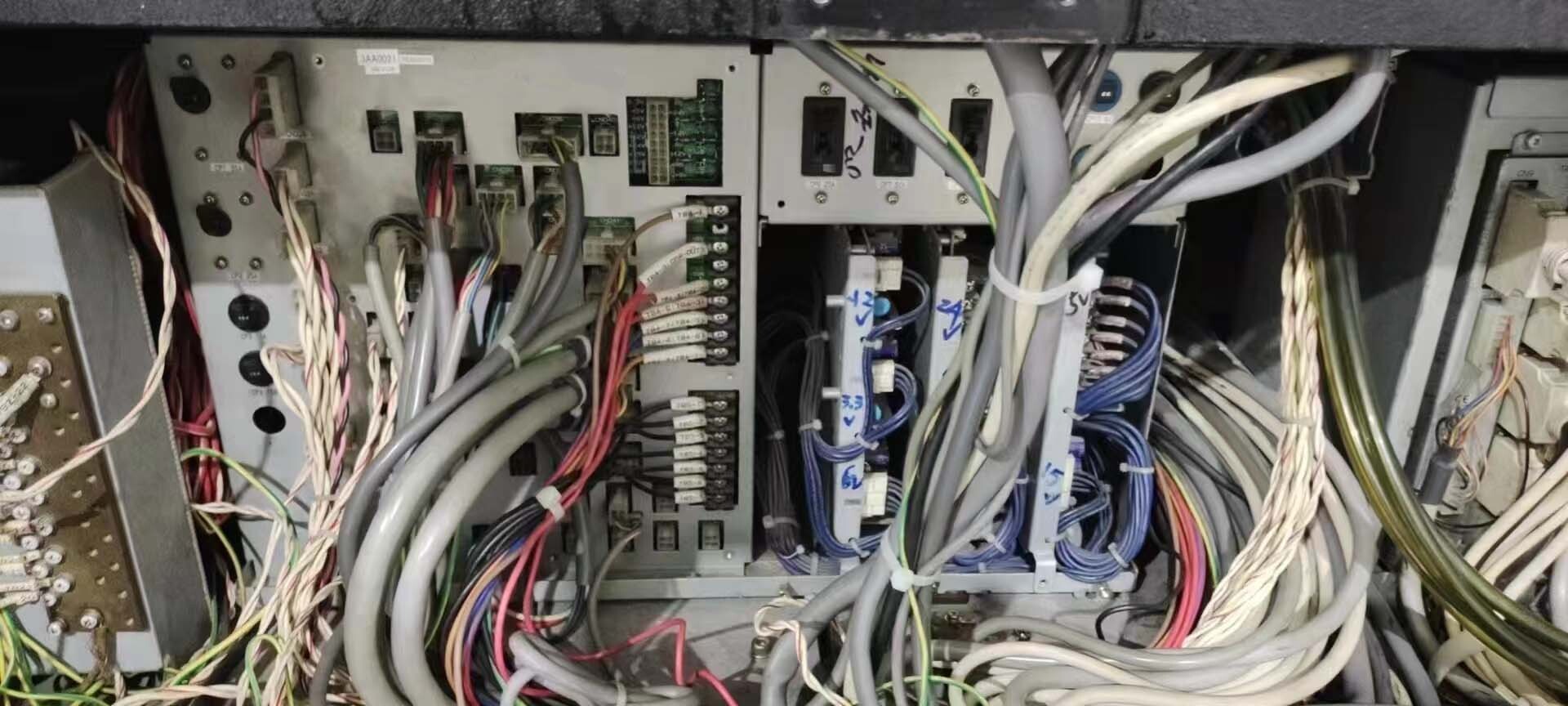

ZEVATECH / JUKI KE 2010L is a pc board assembly and manufacturing equipment designed for surface mount technology (SMT) production processes. It is an automated surface mount placement machine that can be used to place, solder, and inspect all components on a single printed circuit board (PCB) assembly. JUKI KE 2010L offers high speed, accuracy and flexibility in SMT production, and features repeatable accuracy of ±50 microns. The placement process can accommodate components in a wide range of sizes, including 0402 micro SMDs. ZEVATECH KE 2010L has two high-precision moving stages, designed to support Quality-Check-by-Design (QCBD) and Quality-Check-by-Program (QCBP) as part of the SMT workflow. The first stage is the head stage, which moves along the X and Y axis of the printed circuit board. The second stage is the nozzle stage, which consists of up to 16 nozzles and is used to place the components on the PCB. The nozzle stage is equipped with two sensors that detect the location of the placed components to ensure accuracy and repeatability of placement. KE 2010L is compatible with Jet-Printer hot air rework systems and offers an automatic vision camera system. The vision unit can detect defects in components, such as missing and wrong parts, and can be used to track the status of placed parts. Additionally, the vision machine is used to verify the position of the components, and to inspect the solder joints when paired with the JC-500 Solder Inspection Tool. ZEVATECH / JUKI KE 2010L employs a user-friendly touch-screen interface and an intuitive software package that allows users to easily program and control placement and assembly tasks. It is compatible with nearly all types of software programs, such as CAD/CAM, Assembly Manager, and IPC-A-610. The machine is also configurable for any number of lanes needed for a specific job, with a maximum of 7 in JUKI KE 2010L. ZEVATECH KE 2010L is designed for durability and offers years of reliable service life. It employs advanced engineering technology, such as white oil lubrication for X and Y axes and a liquid heater for nozzle temperature control, to ensure consistent and reliable performance. In addition, it is designed to be easily operated, maintained, and user friendly. Overall, KE 2010L is a highly efficient, accurate, and reliable solution for surface mount technology manufacturing, and is suitable for a wide range of applications.

There are no reviews yet