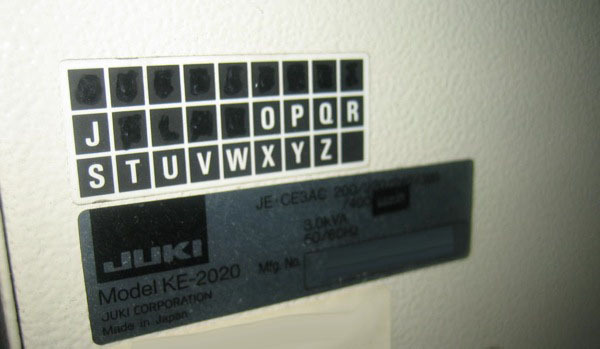

Used ZEVATECH / JUKI KE 2020M #184899 for sale

URL successfully copied!

Tap to zoom

ID: 184899

Vintage: 2002

Chip mounter

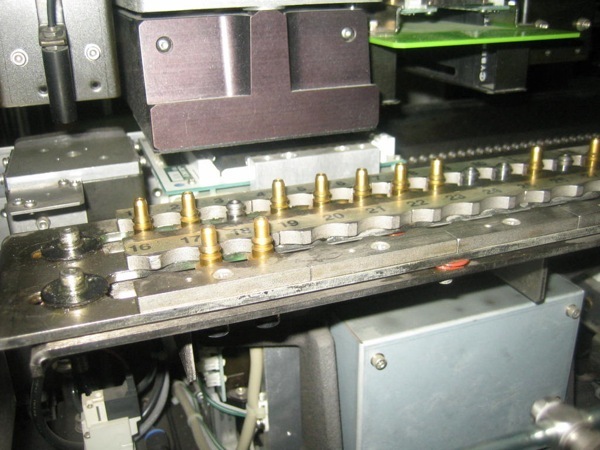

No feeders.

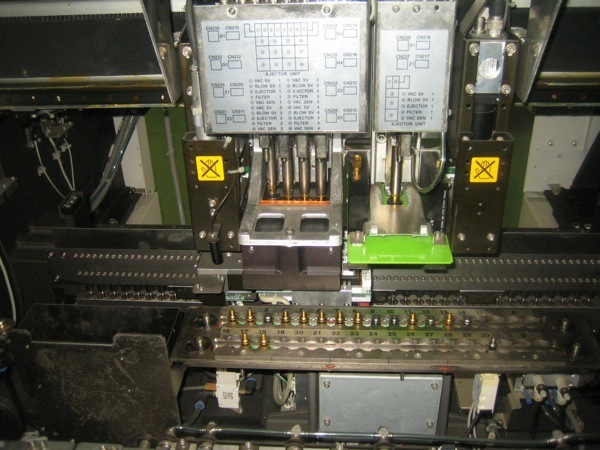

Right to left flow, front fix

No tray changer unit

2002 vintage.

ZEVATECH / JUKI KE 2020M is an innovative PC Board assembly and manufacturing equipment designed to meet the needs of small and mid-sized electronics companies. This system is characterized by its fast, efficient, and highly automated operation, making it an ideal choice for those who need fast throughput and extremely accurate assembles. The unit consists of four major parts: the assembly station, the inspection station, the programming and testing station, and the imaging station. The assembly station is made up of an overhead gantry and multiple pick and place heads. The gantry allows for precise and versatile positioning of components, and the stationary heads have can have up to ten placement nozzles for fast assembly. With an optional ninth head for glue and up to 36 feeders, the assembly station is one of the fastest in the industry. The inspection station consists of a programmable inspection table and high-resolution CCD cameras. This station is used to confirm components and orientations before, during, and after assembly. The programming and testing station is a complete manufacturing line automation solution and passes information from the imaging station, assembly station, and inspection station. This station also runs a thorough test regimen upon completion of assembly to ensure optimal quality. The fourth major part of the machine, the imaging station, is used to precisely measure every component for accuracy and alignment. This station includes an array of sophisticated vision algorithms, including computer generated images, stereo imaging, and motion tracking. The imaging station is also used to accurately measure solder paste, verify component placement, and detect shorts on the board. Overall, JUKI KE 2020M is a highly versatile and automated PC board assembly and manufacturing tool. Its quick and reliable assembly and testing processes are designed to ensure maximum yield, while its imaging capabilities ensure accurate, high-quality boards. With the addition of advanced programming, testing, and inspection, ZEVATECH KE 2020M offers a complete end-to-end solution for electronics companies of any size.

There are no reviews yet