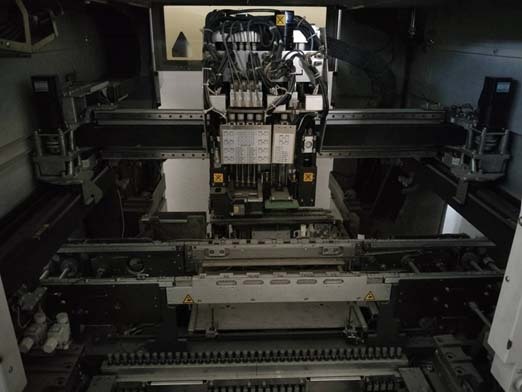

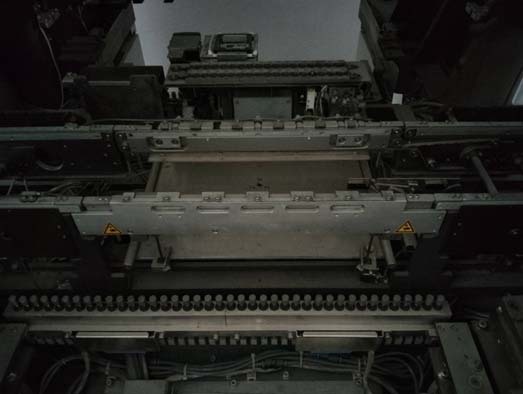

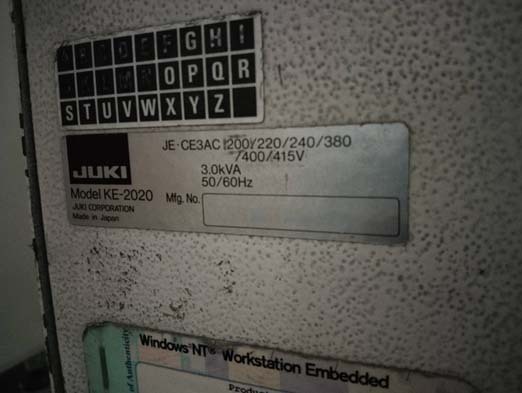

Used ZEVATECH / JUKI KE 2020M #9246569 for sale

URL successfully copied!

Tap to zoom

ID: 9246569

Chip mounter

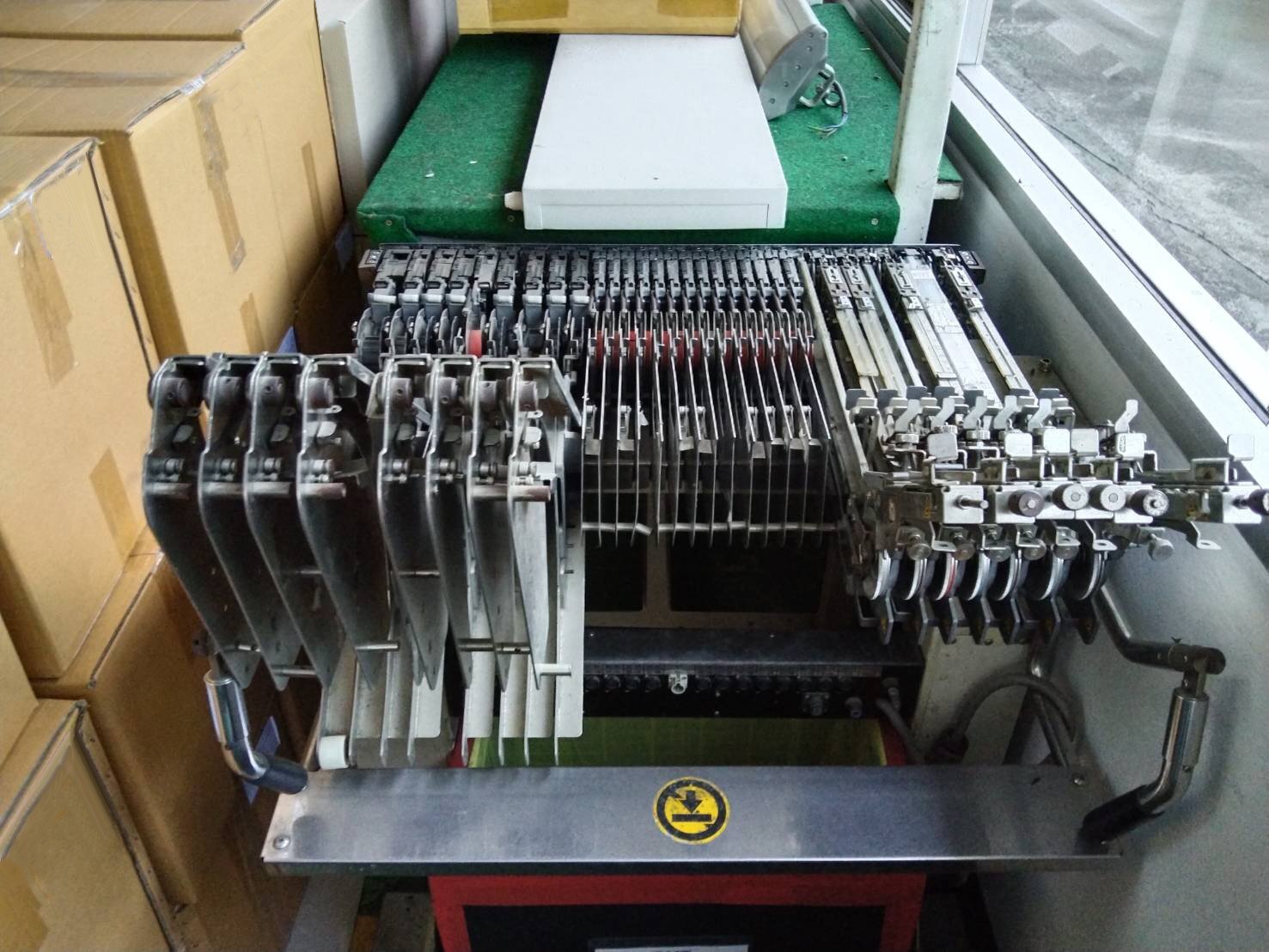

(63) Feeders: 40 x 8 m

(7) Stick feeders

(4) Left heads

Right head

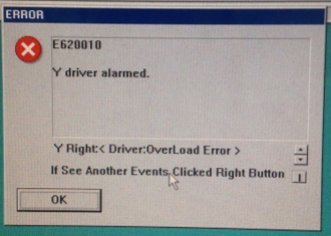

Operating system: Windows NT.

ZEVATECH / JUKI KE 2020M is a PC Board Assembly and Manufacturing Equipment designed to provide high-speed, high-quality production of individually tailored, cost-effective, and flexibly configured electronic circuit board assemblies. The 2020M is equipped with intelligent cameras and lasers that are capable of analyzing the components and board structure with high accuracy. The intelligent cameras are also able to separate color images with sharp focus. Four image processing heads use three features to detect components placed inside the machine and measure them based on positional information, completing the parts recognition process. This process supports highly reliable component positions and alignments. The 2020M's simultaneous dual placement head doubles the speed of placing components in comparison to the single placement head, making the 2020M ideal for high-volume production. Furthermore, the nozzle structures divide into 160 independently controlled zones, allowing control of airflow and ultra-precise placement of components irrespective of their shape. Compared to the past models, the 2020M offers enhanced reduction of insertion force and controlled placement pressure for placement accuracy. Accuracy requirements can be maintained up to 1 mm pitch. In addition, the 2020M supports 2 lines of vision camera, 2 lines of laser head, and double placement heads for high speed placement. It also supports the 3D solder paste inspection (SPI) system for secure, reliable soldering and a highly accurate inspection technology. In terms of post-soldering processes, the 2020M supports a soldering rework station for repairs and reworks support. PCBs larger than the component placement range are worked on in two (or more) steps. In addition, the 2020M is able to read data codes, such as barcodes, and device serial numbers using the integrated image recognition and optical character recognition functions. Furthermore, as a training and evaluation unit, the 2020M supports customer simulation and remote customization operations. Operators can see a 3D simulation of operation data and upload and modify settings and programs remotely. The 2020M also boasts AI algorithms for auto learning of board characteristics and provides graphics data and work instructions that aid operators, resulting in high-precision, user-friendly operation. In conclusion, JUKI KE 2020M is a sophisticated and user-friendly PC Board Assembly and Manufacturing Machine. Boasting a powerful combination of technologies, it sets a new benchmark in speed, accuracy and flexibility.

There are no reviews yet