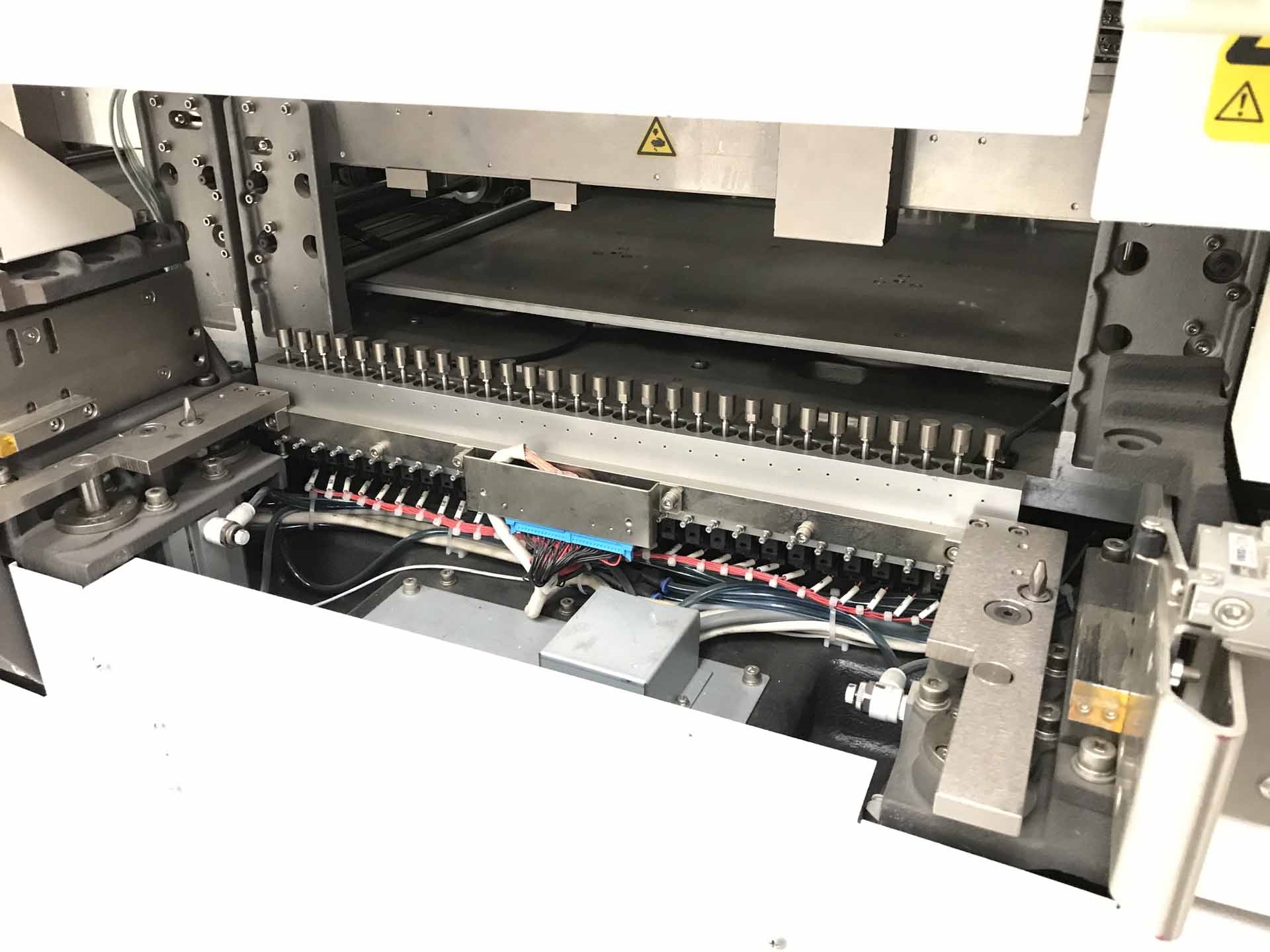

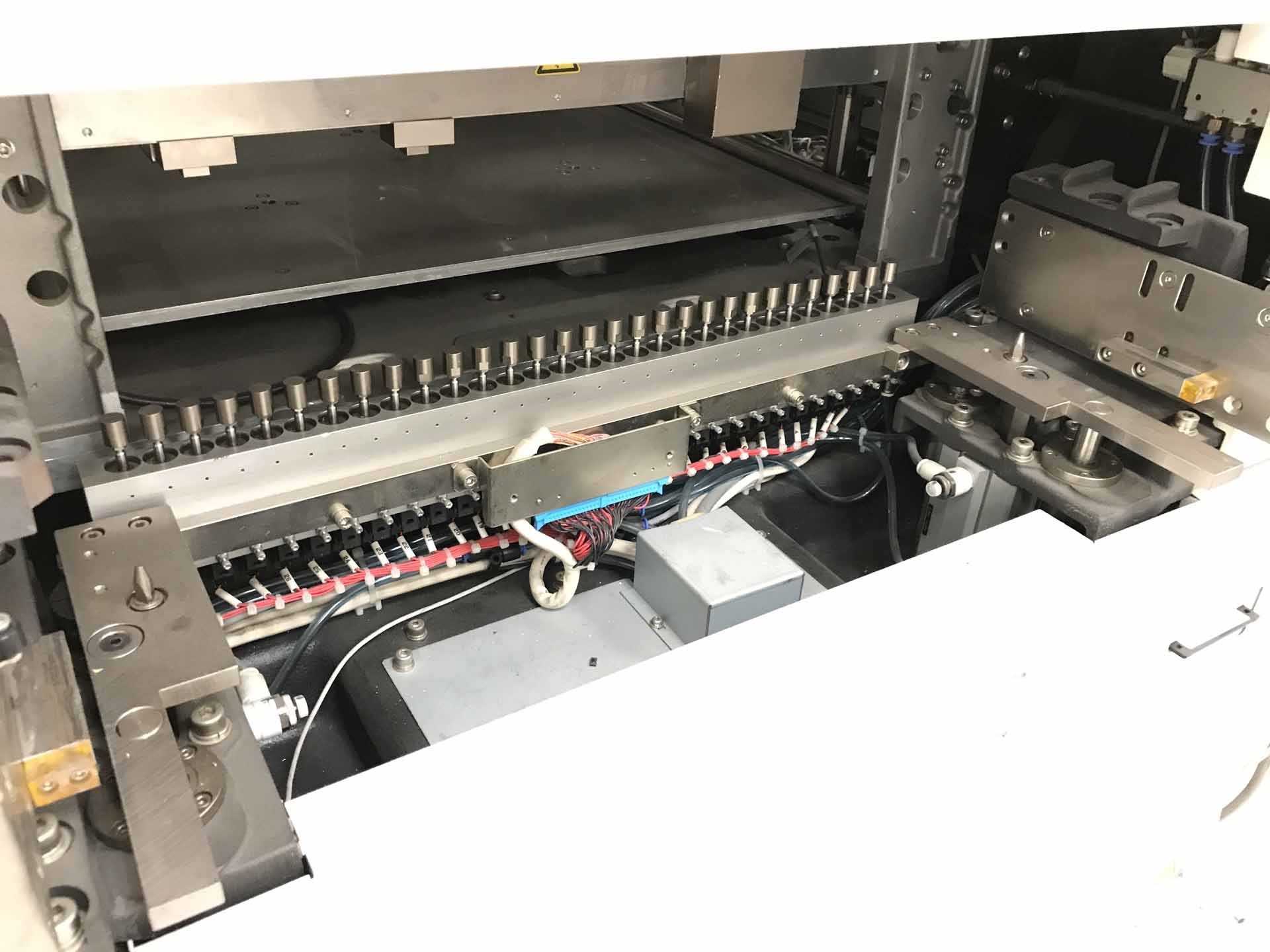

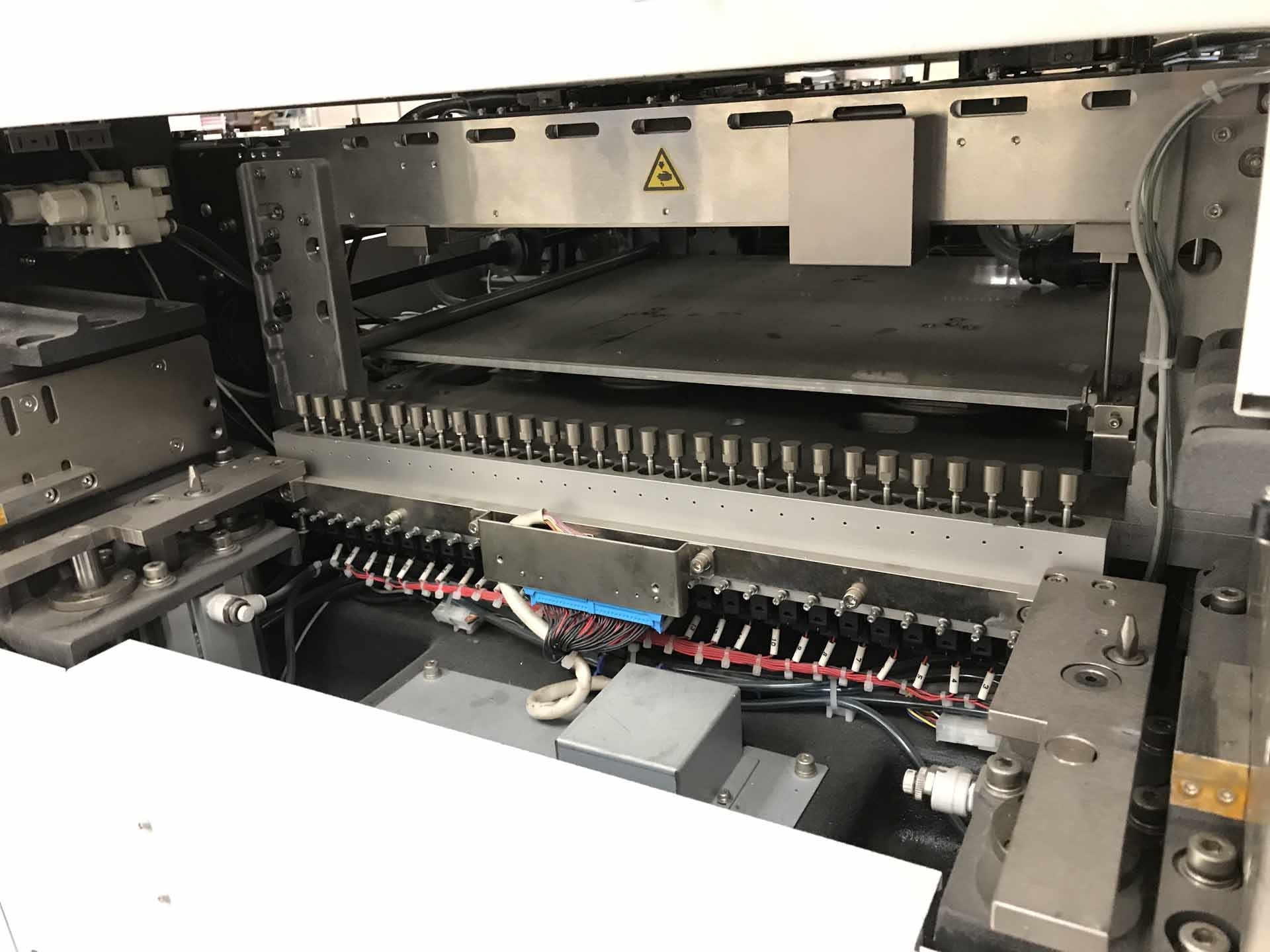

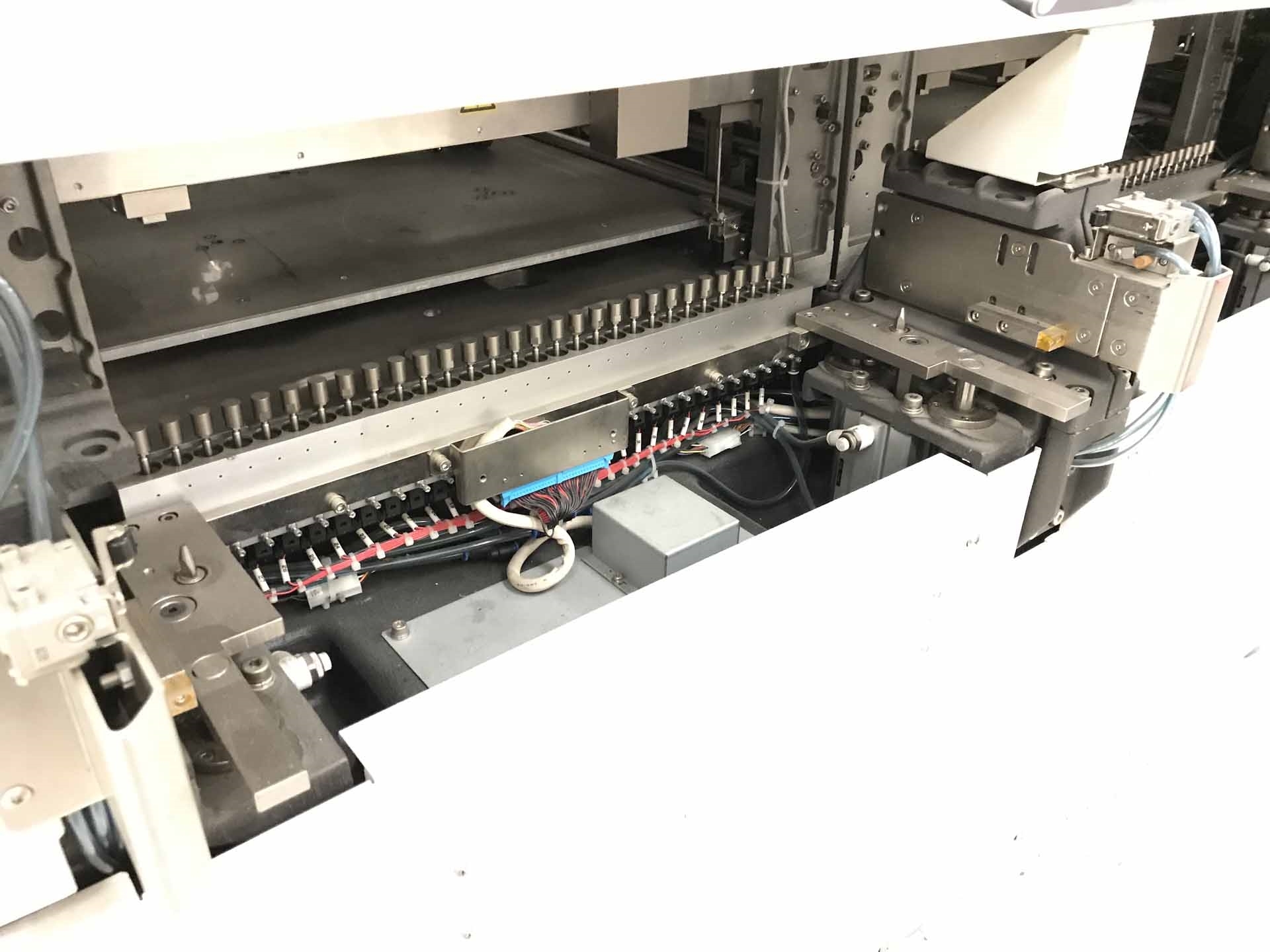

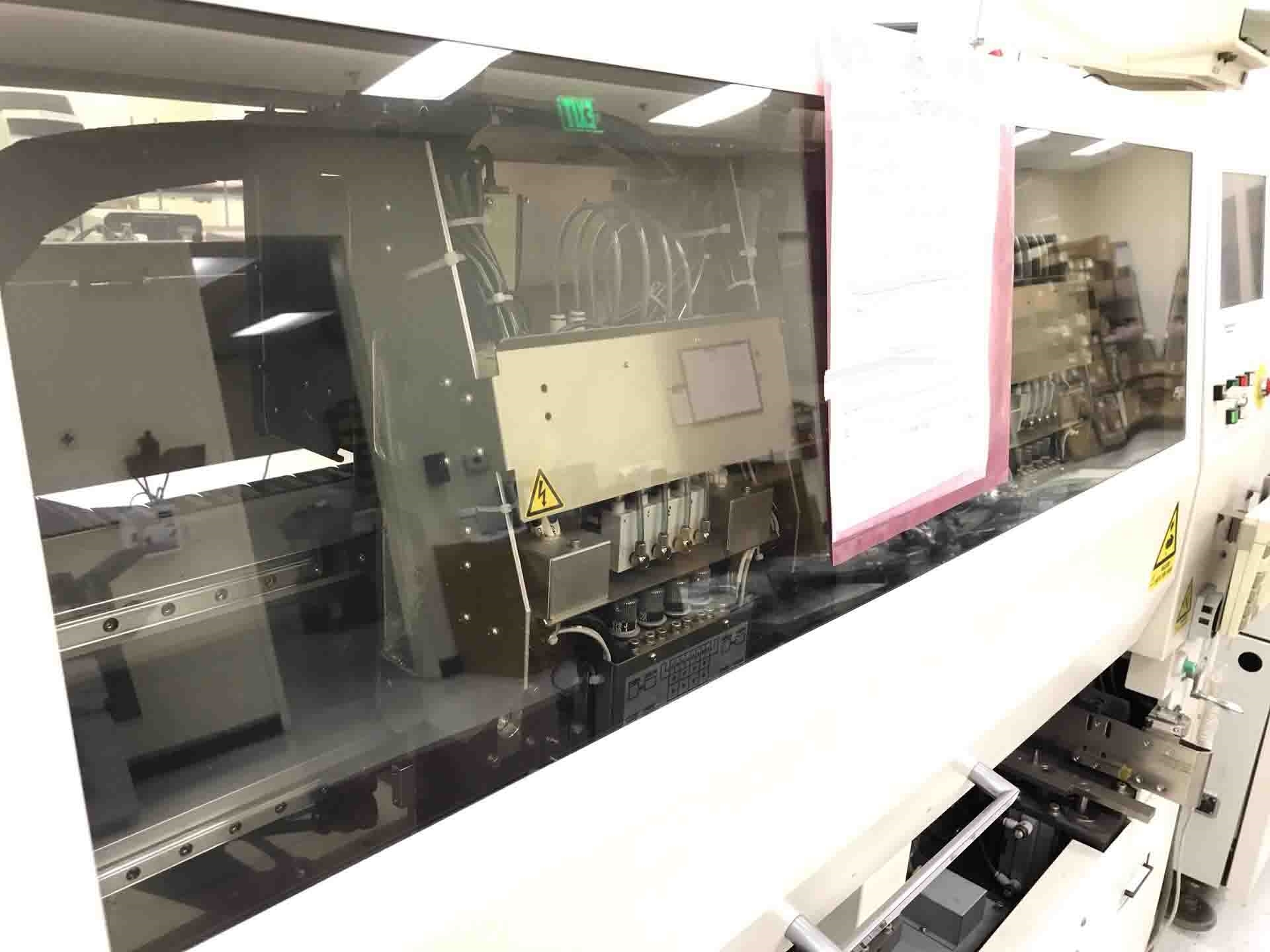

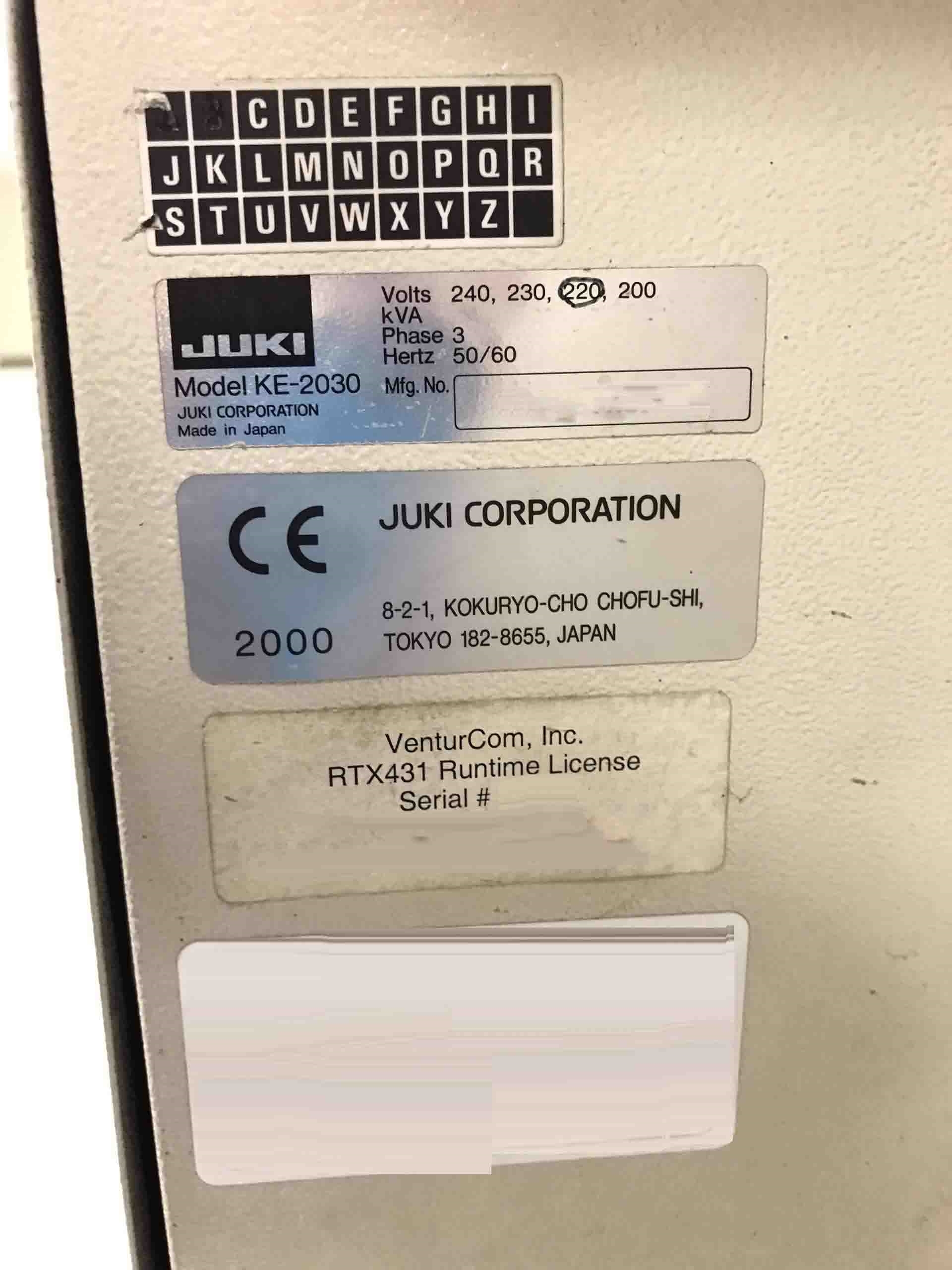

Used ZEVATECH / JUKI KE 2030 #9182340 for sale

URL successfully copied!

Tap to zoom

ID: 9182340

Vintage: 2000

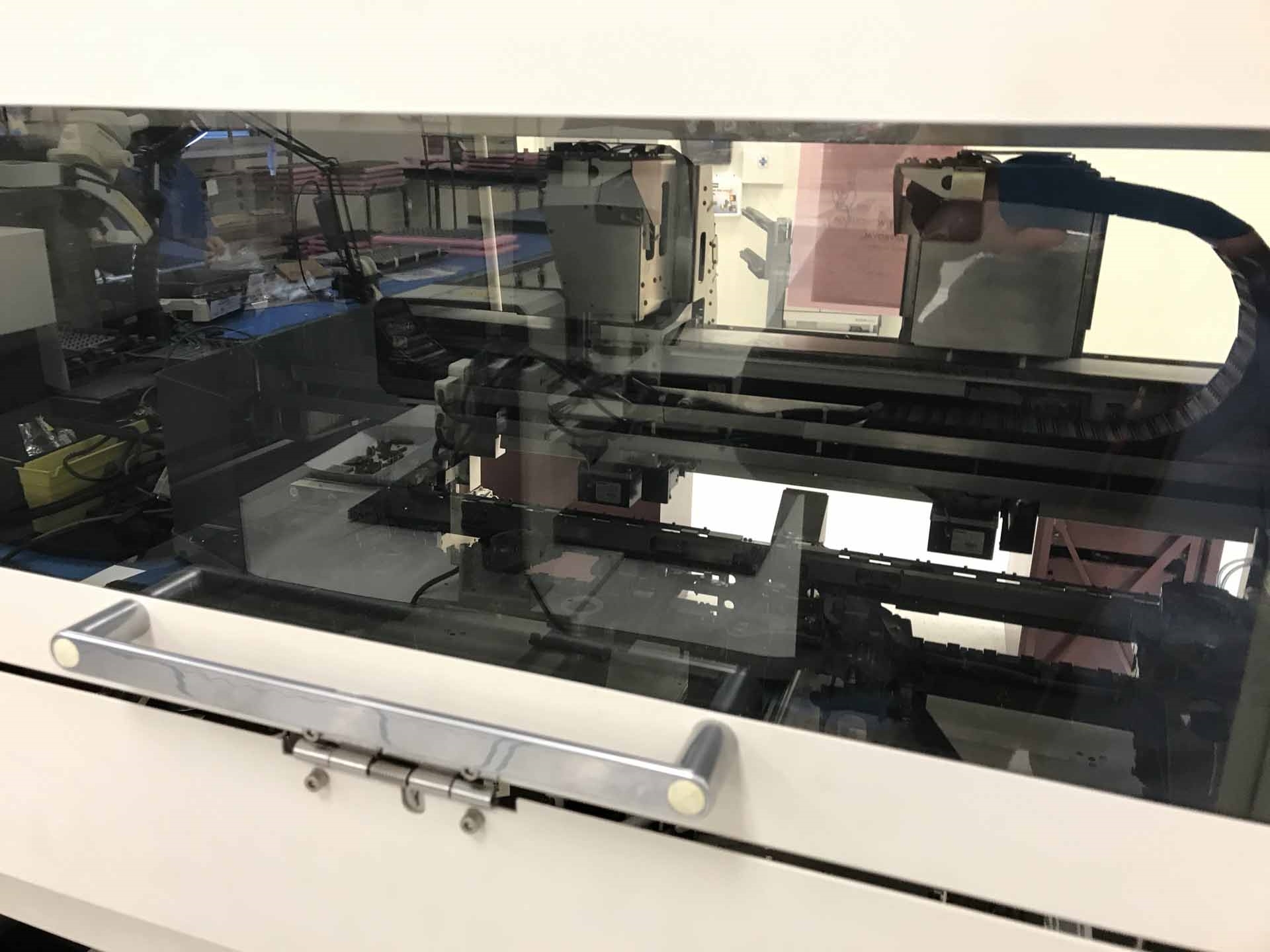

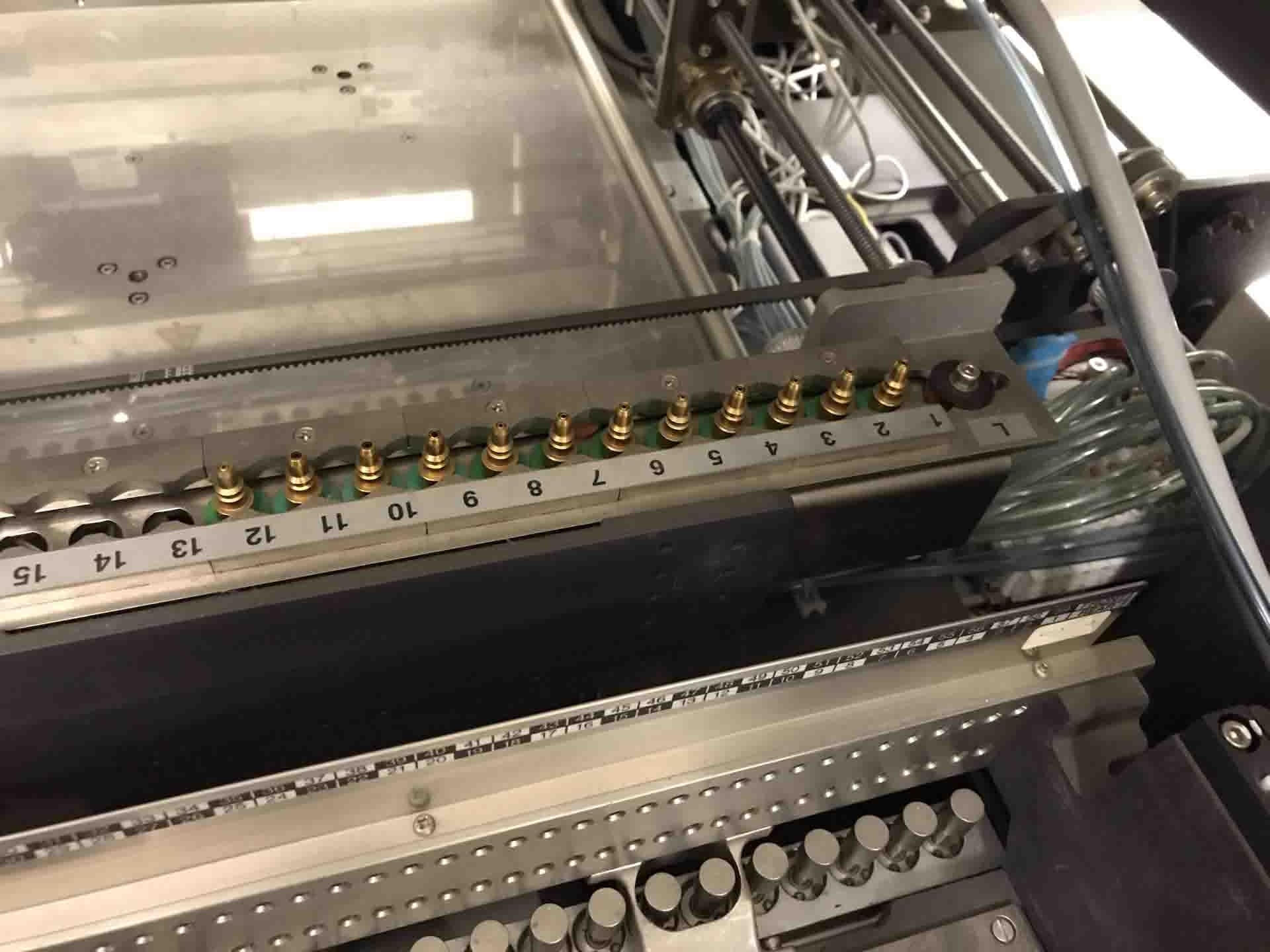

Pick and place machine

Machine flow: Left to right

2000 vintage.

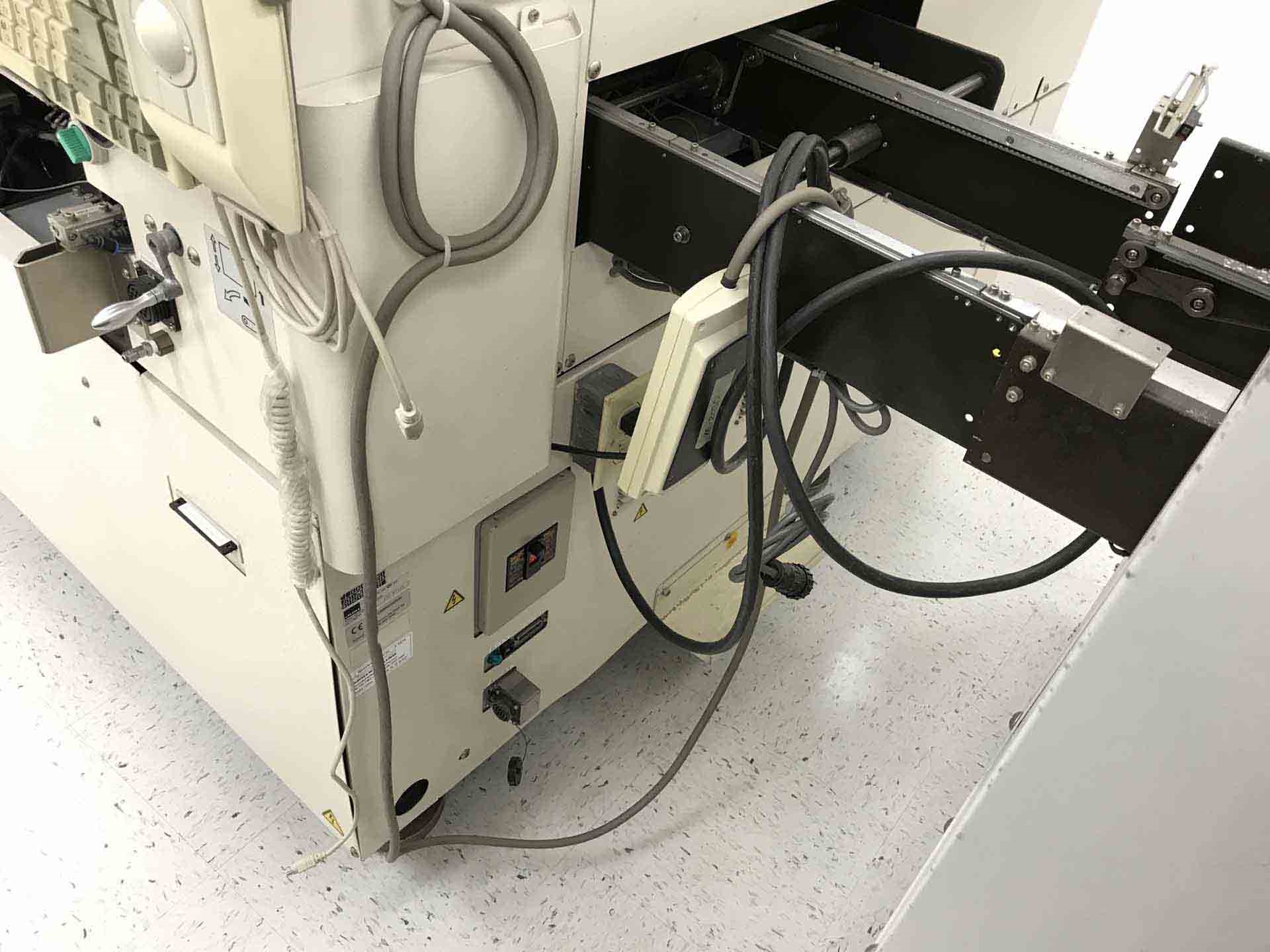

ZEVATECH / JUKI KE 2030 is a computerized printed circuit board assembly and manufacturing equipment. It is designed for high-speed and accurate production of various types of boards. The system comprises three core components: a Machine Control Unit (MCU) responsible for the precise operation of all machines, a relatively high-performance computer with some specialized hardware for board recognition and verification, and x-axis and y-axis manipulators for precise movement of components on the board. It is often used for a variety of production lines, such as automotive electronics, transistors, and semiconductors. The MCU communicates with the computer through a dedicated communication protocol, and its primary tasks include adjusting the spindle speed of the feeder, controlling vacuum and electricity, controlling the over-travel mechanism and the load cell, plus board recognition and verification. The MCU is capable of recognizing up to three double-sided panels at once and can handle boards from 0.5 to 8.8 mm thick. The Computer runs on either x86-based Windows or Linux operating unit and includes a good set of peripherals, most of which are focused on board recognition and verification. It can recognize boards of up to 12 x 12" in area and supports a variety of communication protocols, from raw Ethernet to TCP/IP. The x-axis and y-axis manipulators are designed to handle components of different sizes and shapes, with adjustable travel distances and speeds. The manipulators operate independently, allowing each component to be precisely placed on the board within very tight tolerances. To ensure accuracy, the manipulators are equipped with three vacuum pickups and a small camera to measure component and board dimensions. To further aid in orientation and placement accuracy, JUKI machine comes with a vision tool, which can provide real-time images of components on the board. This allows for more accurate placement of components and reduces the risk of component cross-talk. It also features a number of additional tools, such as a vacuum plate for easy placement of components and a needle detector for safe removal and placement of components. Overall, JUKI KE 2030 provides high- speed and accuracy for assembly and manufacturing of various types of boards. Its integrated vision asset ensures accurate placement of components and its robust MCU and computer make it a reliable, efficient, and cost-effective solution for modern production lines. With its reliable performance and wide range of features, ZEVATECH KE 2030 model is an ideal investment for any manufacturer.

There are no reviews yet