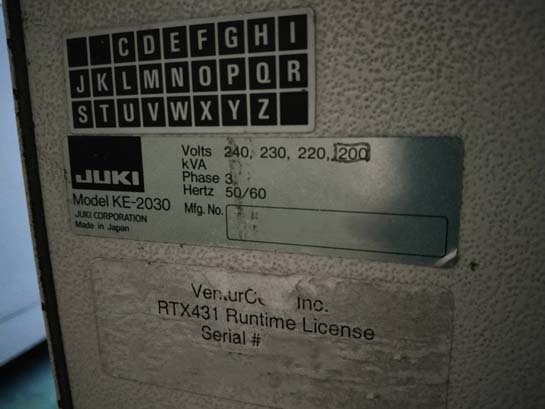

Used ZEVATECH / JUKI KE 2030 #9246570 for sale

URL successfully copied!

Tap to zoom

ID: 9246570

Chip mounter

Dual head

With (4) Nozzles

Does not include feeders

Operating system: Windows NT.

ZEVATECH / JUKI KE 2030 is a PC board assembly and manufacturing equipment combining high performance components, robust design, and user-friendly operation. The system is capable of producing high-quality boards with high yields due to its advanced components such as Surface mount technology (SMT) feeders with automatic component recognition and feed correction, an efficient four-axis transport, a custom-fit walking beam conveyor, and optimized parts presenters. The unit is equipped with a high-speed vision machine for inspection and placement accuracy. This tool supports optical and X-ray inspection functions to check placement positions as well as detection of shorts and opens. Additionally, the edge-straddling (ES) placement technology supports flexible and high-speed placement of part sizes down to 01005. The asset is also designed to simplify operation, reduce setup time, and ensure a low cost of ownership. Real-time support is provided through a built-in Web server interface at the machine, while user-friendly functions like teach mode, auto-detection of tape-type or tray-type components, IC packages and monitors, along with 25 library storage settings for programs, allow users of various skill levels to easily program the model. Aside from the above, the equipment also supports JUKI Lean Flex component rework system, which allows for easy reprogramming and replacement of components at the motion speed of the main unit. This allows for efficient repairs with minimal time and cost. JUKI KE 2030 is an impressive machine for PC board assembly and manufacturing, offering both high performance components and features to make operation simple. Its fast-paced operation, highly accurate placement operations, and effective rework tool make it the ideal choice for a manufacturing line.

There are no reviews yet