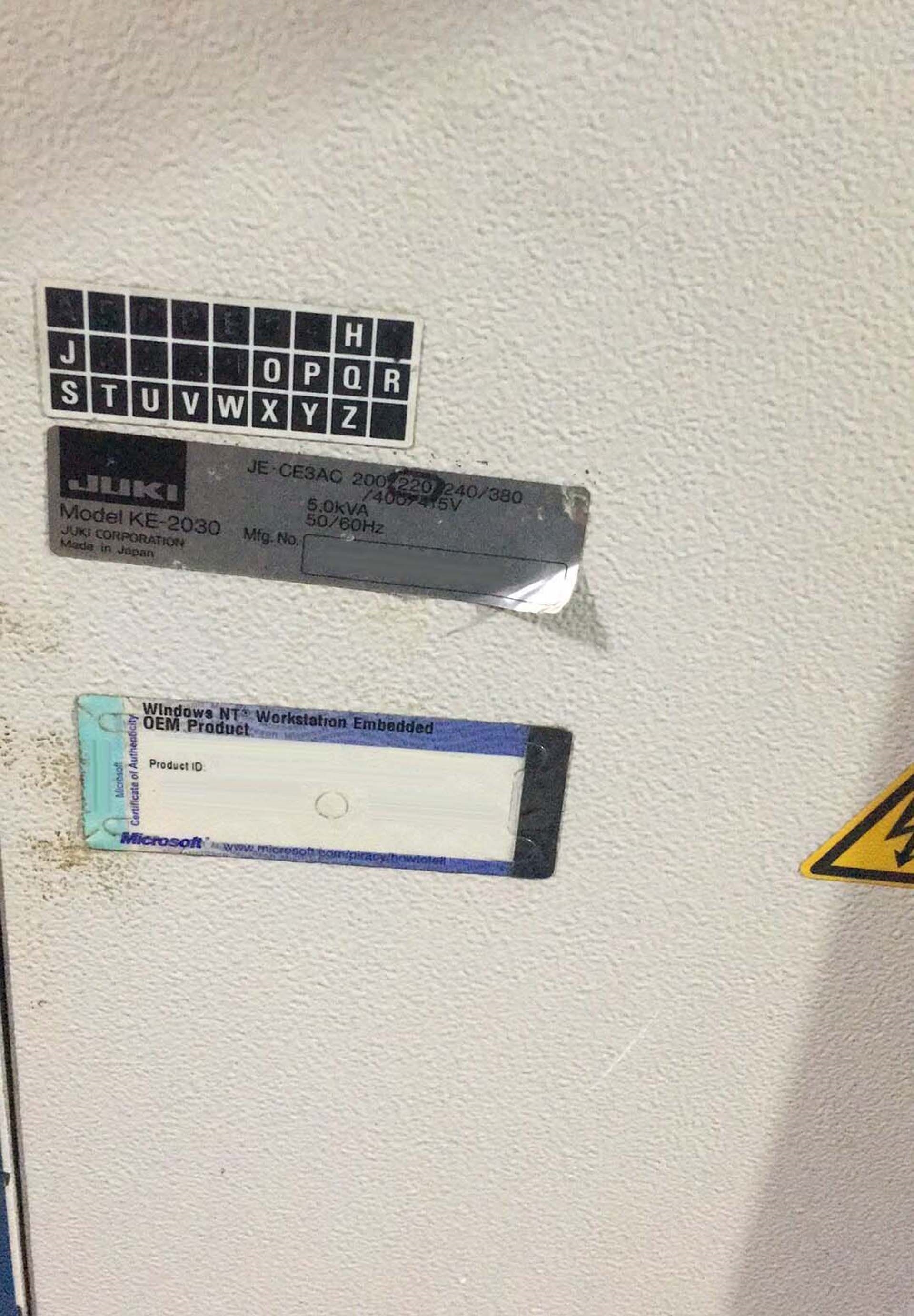

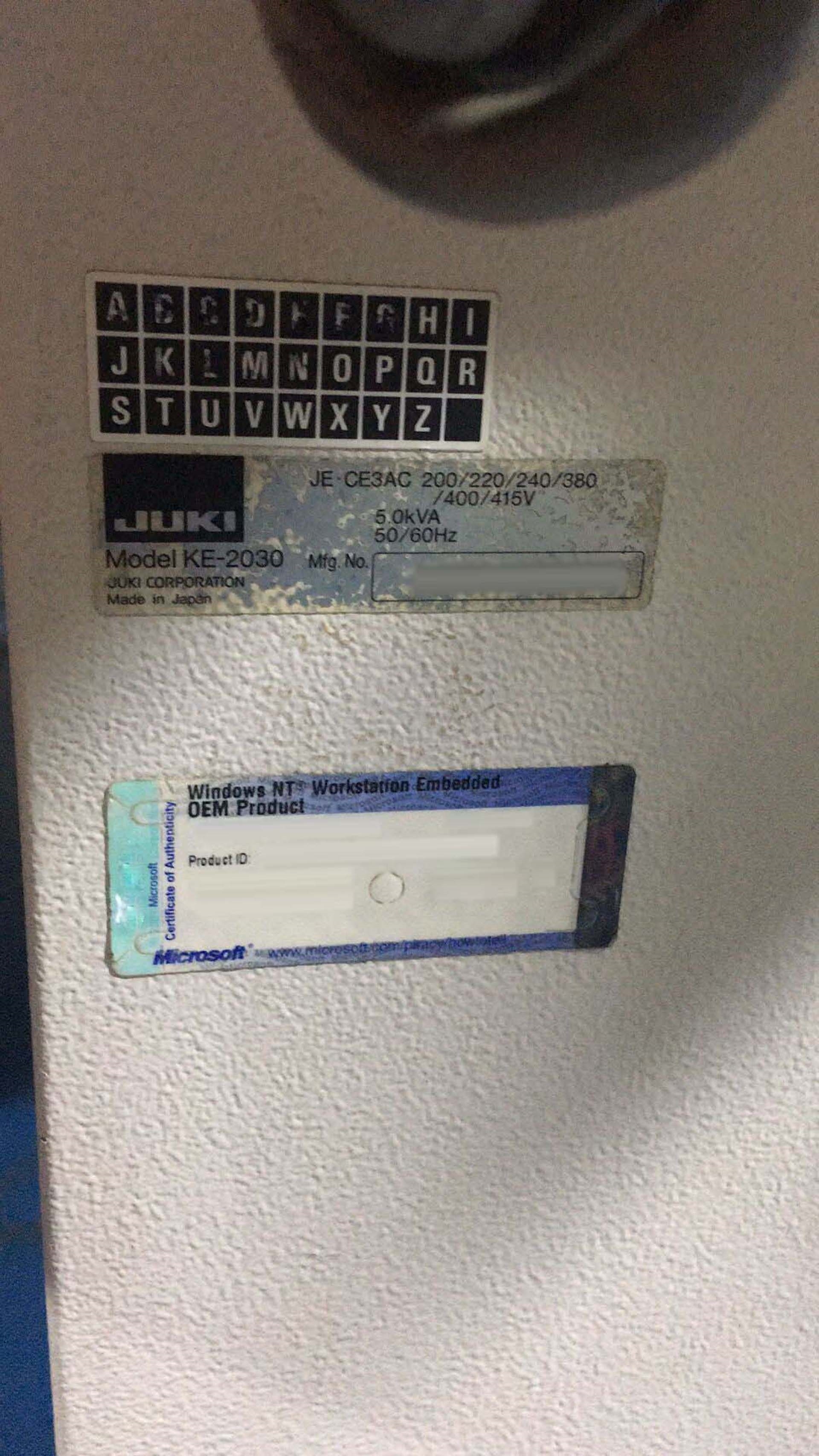

Used ZEVATECH / JUKI KE 2030 #9247416 for sale

URL successfully copied!

Tap to zoom

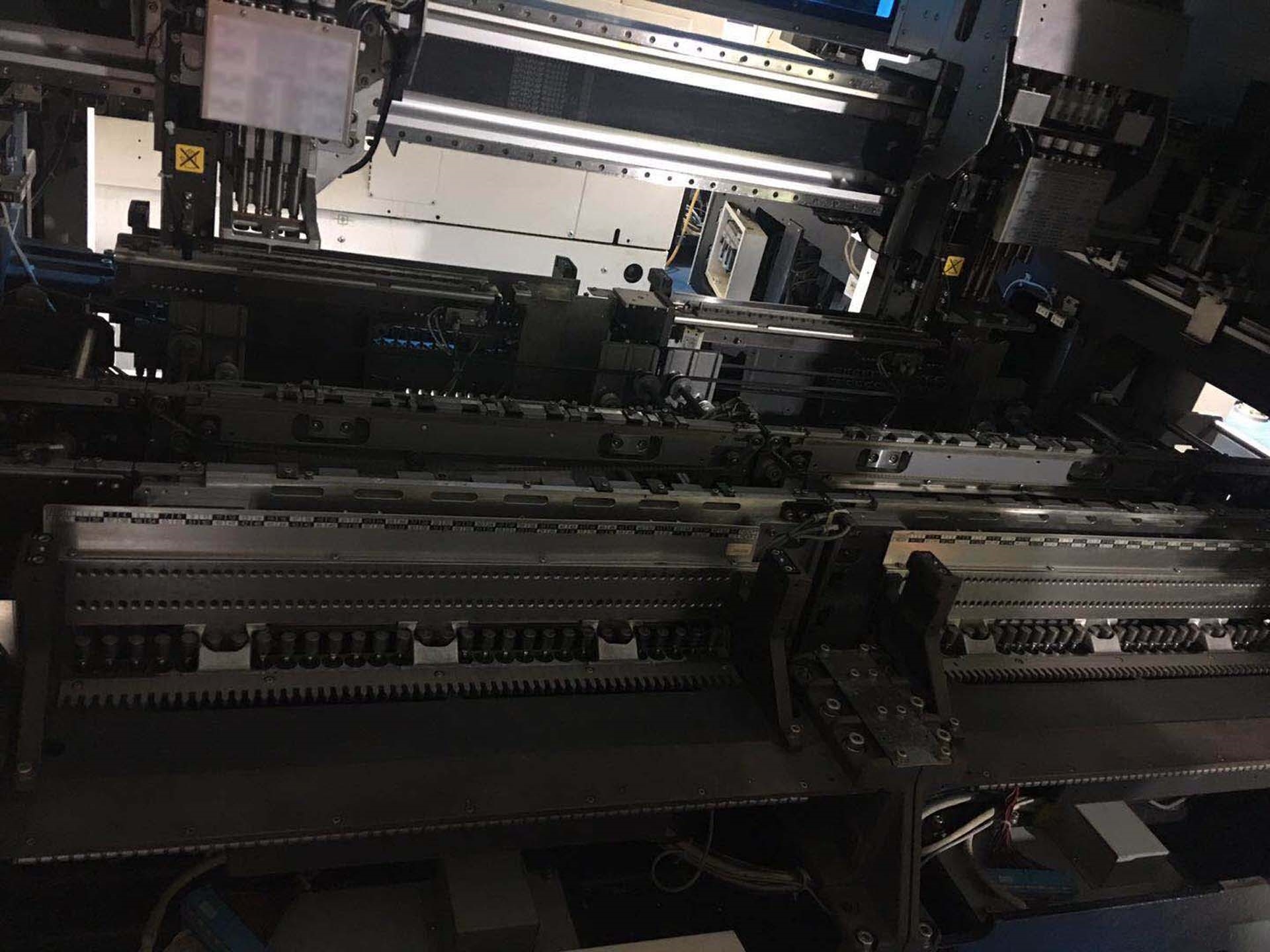

ZEVATECH / JUKI KE 2030 is an advanced and versatile pc board assembly and manufacturing equipment. This system is capable of performing both surface mount technology (SMT) and through-hole technology (THT) operations. It is equipped with a high-performance, 10-spindle mounter, which can be used for the assembly of components on various substrates. The mounter features a double-railed, high-speed and precise, chip mounter design for up to 15,000 components per hour. The double-railed mechanism also allows for accurate mounting of components with a tolerance of ±0.1mm. The unit also includes an advanced JUKI RS-M2 robot that is capable of carrying out vision and pick-and-place operations efficiently and accurately. This robot is specially designed to be used with SMT operations and is capable of mounting components on both sides of the board. It can also accurately position the components in the appropriate position on the board. JUKI KE 2030 also features a state-of-the-art camera machine that can be used to inspect the components during the assembly process. This tool features both an RGB and UV asset that can be used to ensure the quality of the components and their placement on the board. The camera model is also used to precisely place the components on the board. The equipment is designed to offer a great degree of accuracy in the assembly process. It features a high-speed, high-accuracy vibration feeder system that accurately places components onto the board at up to 3,000 cph. The feeders also allow for a wide variety of components to be placed in just a few seconds. In order to ensure maximum performance from the unit, it is equipped with an advanced power management machine. This tool is designed to ensure that all of the electrical components of the asset are supplied with constant voltage and current. This helps prevent any electrical issues during the assembly process. Finally, ZEVATECH KE 2030 is equipped with a user-friendly interface. This makes it easier for users to configure and customize the model according to their needs. The user-friendly interface also allows users to monitor the progress of the assembly process and troubleshoot any errors.

There are no reviews yet