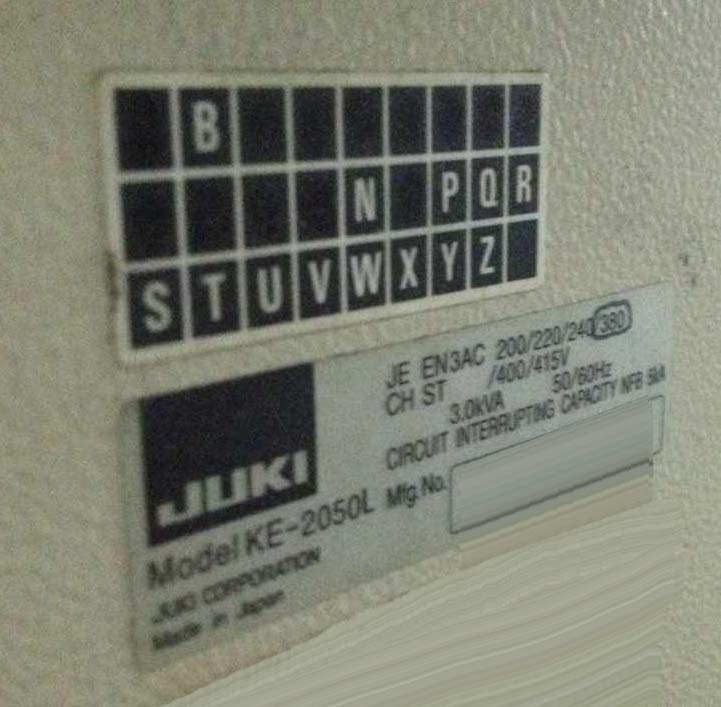

Used ZEVATECH / JUKI KE 2050L #9070425 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2050L is a pc board assembly and manufacturing equipment designed to streamline production and streamline the production of printed circuit boards. This system combines high quality components, advanced vision technology, and user-friendly software to provide fast, accurate, and cost-efficient production. The unit is capable of producing printed circuit boards (PCBs) of various sizes and configurations with the utmost of precision and reliability. It consists of multiple components, including an industrial-grade machine, vision camera, feeders, intelligent pre-programmed computer software, and hardware components. The tool uses a unique asset architecture, consisting of a controller, vision camera, peripheral components, and adapter interfaces. This model architecture is designed to allow high-accuracy control and analysis of PCBs. In addition, the equipment provides full support of the CAD/CAM process, providing full compatibility and integration. JUKI KE 2050L utilizes vision camera technology to detect and identify printed components, as well as the shape, size, and location of the components. The vision camera is linked to the industrial controller, providing improved accuracy and precision for the process. Additionally, the system is capable of recognizing and identifying various feeders, and routing them to the proper receptacles. The unit also uses intelligent pre-programmed computer software to program and control the machine. This software is designed to work seamlessly with the camera and the controller, providing a high level of automation and accuracy. Furthermore, the machine can be programmed to recognize various components, and feed them to the designated locations accurately. Additionally, the tool provides full support of the CAD/CAM process, providing integration with various software applications. The asset also includes multiple hardware components to increase the accuracy and speed of the processes. These components include an automatic component insertion machine, board protection covers, and a testing module. The components are designed to provide a high degree of accuracy and precision, as well as safety features to protect the boards from damage. Overall, ZEVATECH KE 2050L is an advanced model for the production of printed circuit boards. It offers a high degree of automation and accuracy, with dynamic speed and accuracy settings, as well as an intelligent pre-programmed computer software. In addition, the equipment includes several hardware components, designed to increase the accuracy and speed of the overall process.

There are no reviews yet