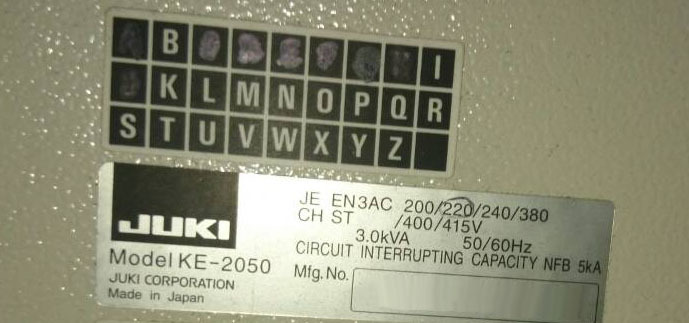

Used ZEVATECH / JUKI KE 2050L #9072123 for sale

URL successfully copied!

Tap to zoom

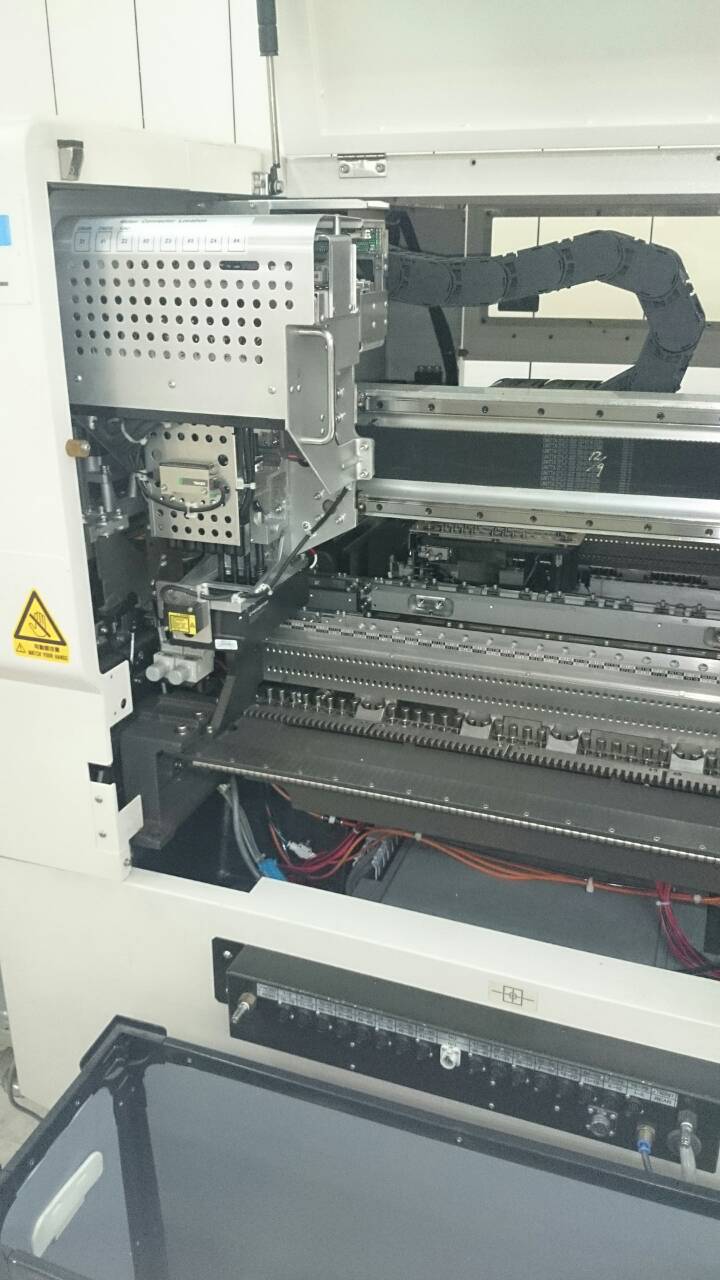

ZEVATECH / JUKI KE 2050L is a high-speed, high-precision PCB assembly and manufacturing equipment. It is equipped with several advanced features that enable maximum cycle times and board handling capabilities. The system is capable of processing boards up to 600mm in length and up to 0.2mm in thickness. The unit offers users a top-of-the-line vision recognition machine that can quickly detect components and their orientations. The vision tool accurately measures components and generates precise placement data to ensure that all parts are placed with precise accuracy. The vision asset also has multiple layer inspection model to detect and reject defective boards. The equipment offers five axis motion control in order to reduce the time and cost of assembly. The dual motor driven X, Y and Z axes allow for high-speed, high-precision component placement. The system also uses high-sensitivity force feedback sensors and force control to pick up and place components as small as 0201 with repeatable accuracy and low cycle times. The unit is equipped with a high-capacity flying nozzle that can pick and place up to 4,800 components per hour. The placement head is capable of working at the highest speeds without compromising accuracy for parts of all sizes. The machine also has two 8-component chip shooters that can feed and place components directly on the board quickly and accurately, allowing for even further cost and time savings. The tool also features a high-speed, double-row DC power pin feeder that can place up to 24 pins per second with perfect accuracy. This ensures that power pins are placed accurately without having to manually place them onto the board. JUKI KE 2050L PCB assembly and manufacturing asset is a top-of-the-line model that can quickly produce high-precision boards with minimal costs and time. It offers maximum cycle times and board handling capabilities, while the fly-nozzle and chip shooters can facilitate cost savings and time-savings. It also offers a reliable vision equipment and force feedback sensors for precise component placement.

There are no reviews yet