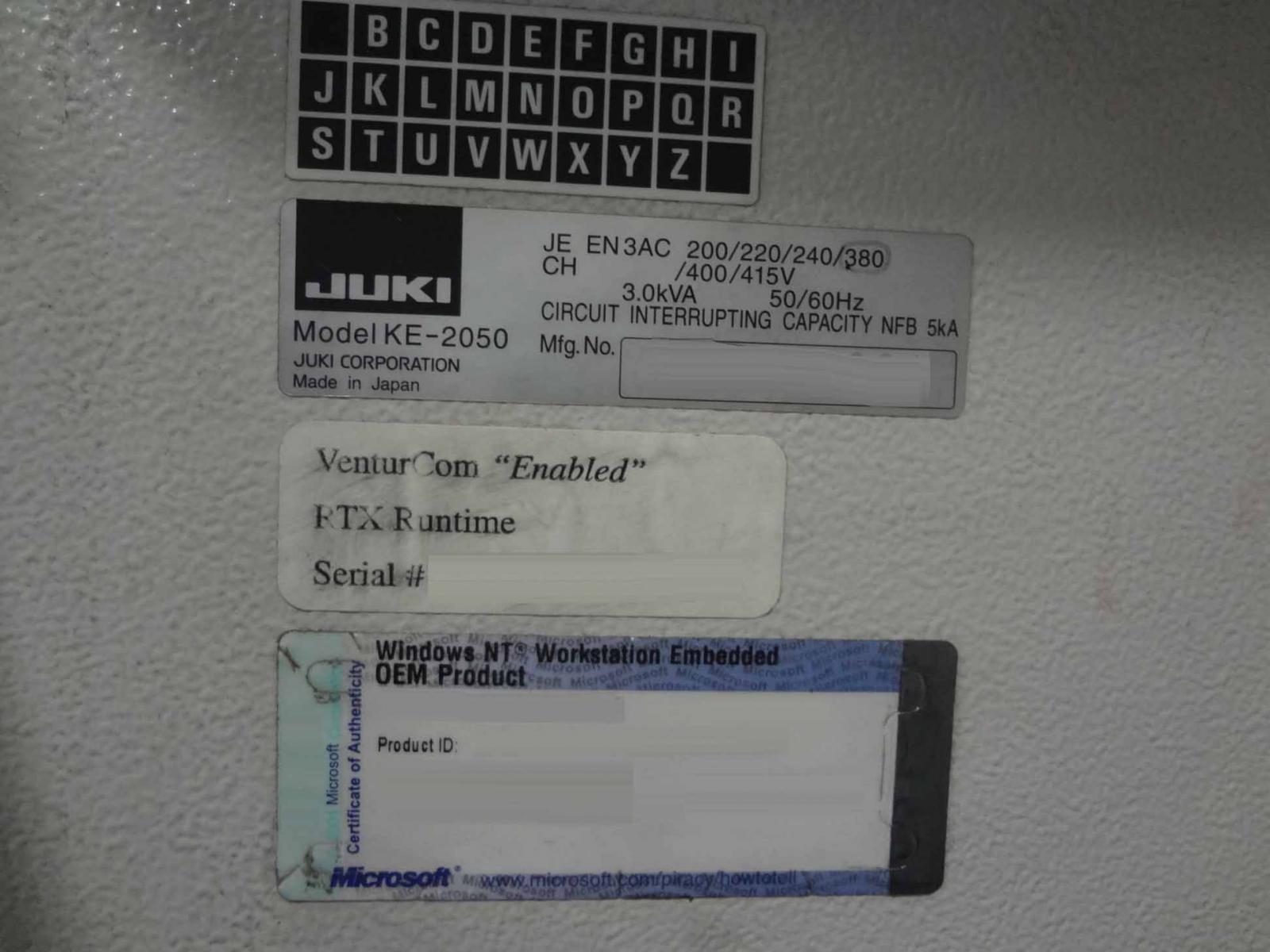

Used ZEVATECH / JUKI KE 2050L #9094178 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2050L is a high-speed, dual-beam, laser-based PC board assembly and manufacturing equipment. This system is designed for maximum efficiency and flexibility in a wide range of circuit board assembly and testing applications. It offers a unique combination of features to meet today's emerging needs for high-volume manufacturing and testing of printed circuit boards. JUKI KE 2050L features a dual-beam laser unit, allowing for maximum flexibility. Laser processing is faster and more accurate than traditional techniques, and it has the ability to cut through even the densest materials with extreme precision. The machine also features a high-powered laser with various focal lengths, allowing for application-specific adjustments to overall accuracy. The tool also features a single-slot, dual-function test module. This module gives engineers the flexibility to test multiple components on a single board, while also taking advantage of the test capabilities of ZEVATECH KE 2050L. It also has a range of user-defined parameters, including product recognition capabilities, pattern recognition measure lengths, error codes, and more. This allows the user to tailor the test parameters and inspections to specific board designs and requirements. KE 2050L also features integrated software for easy setup and programming. The intuitive user interface makes it easy for users to get up and running quickly, and the programming options are extensive, allowing for fast and precise circuit board programming. Additionally, the asset offers industry-leading fault detection, defect recognition, component mapping, and defect analysis capabilities for enhanced defect detection and troubleshooting. In addition, ZEVATECH / JUKI KE 2050L model provides for in-line soldering and automated component placement. This enables engineers to quickly and accurately place a variety of components on the board, in addition to soldering them. This helps ensure zero errors in assembly and can save time and money in the long run when it comes to repeating tasks. JUKI KE 2050L is a high-end PC board assembly and manufacturing equipment that allows for maximum efficiency and flexibility in a variety of board assembly and testing applications. It is capable of performing rapid prototyping, production, and fault diagnosis by combining an array of features, including a dual-beam laser, single-slot dual-function test modules, automated component placement, and advanced software for program setup. Generally, the system has been designed and tested for the highest quality for continuously satisfying the most challenging manufacturing demands.

There are no reviews yet