Used ZEVATECH / JUKI KE 2050L #9156823 for sale

URL successfully copied!

Tap to zoom

ID: 9156823

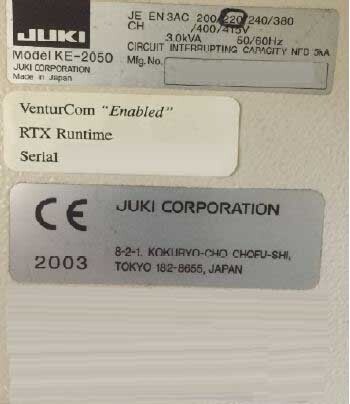

Vintage: 2003

Pick and place machine

(20) Feeders

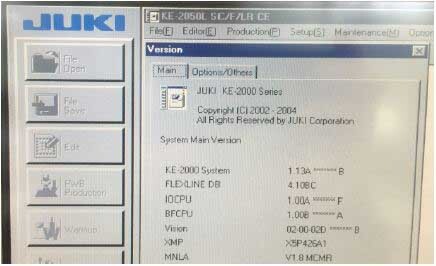

OS: Microsoft Windows NT 4.0

Board Size: L size (410 x 360mm)

Component height: 6mm

Component size: 01005 (0402 metric) ~20x20mm or 26.5x11mm

Placement speed: 13,200 CPH

Placement accuracy: Laser = ± 0.05mm (Cpk 1)

Feeder inputs: Max. 80 on 8mm tape feeder

Power supply: 200 to 415 VAC, 3-phase

Apparent power: 3kVA

Operating air pressure: 0.49 ± 0.05 Mpa

Air consumption: 230L/min

2003 vintage.

ZEVATECH / JUKI KE 2050L is a pc board assembly and manufacturing equipment designed for providing large-scale production of computer boards. It is capable of producing boards containing up to 128 components, and can produce boards at an impressive speed of up to 60,000 modules per hour. Along with its impressive production capacity, the system boasts many features that ensure a high-quality finished product. JUKI KE 2050L utilizes a modular design to ensure composability and flexibility in production. It has a Gantry Cartesian positioning unit which uses X, Y, and Z axis positioning to precisely locate components. The motors in this machine are driven by brushless servo motors, which provide fast stepper control for rapid and accurate positioning. The tool is also equipped with vision control, which is used to perform component alignment and verification. This asset also has an amazing tolerance level of ±50 µm, which allows for precise pick-and-place operations and placement accuracy. In addition to the impressive features of its design, ZEVATECH KE 2050L also has several manufacturing-specific features that make it an ideal choice for pc board assembly. It utilizes a high-powered laser for through-hole application and has the ability to program up to 1 million unique sets of pathways for solder paste printing. There is also an optional conductive adhesive dispenser available, providing a reliable alternative for high-speed adhesive application. The modular design also allows for multiple functions to be combined, leading to increased production abilities. KE 2050L also offers several convenience features to further enhance its level of performance. There is an intuitively designed user interface that allows operators to quickly create and manage programs, as well as a built-in model for tracing components. Additionally, the equipment has the capability to trace defects and diagnose problems, making troubleshooting quick and easy. Moreover, integration with other automated systems is available, allowing for production systems to be linked together for a fully automated production environment. Overall, ZEVATECH / JUKI KE 2050L is an impressive piece of machinery for pc board assembly. With its powerful design and features, it is capable of producing high-quality manufactured products at extremely fast speeds. By providing a variety of convenience features, the system ensures that production operations remain efficient and effective. With its impressive capabilities and features, JUKI KE 2050L is sure to be the perfect choice for any pc assembly operation.

There are no reviews yet