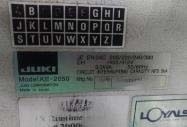

Used ZEVATECH / JUKI KE 2050L #9281448 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2050L is an advanced, state-of-the-art pc board assembly and manufacturing equipment designed to fast track production process. It is a multi-functional platform, offering integration of various automated processes from component placement to dispensing, verification and post-print printing processes. The machine uses a standardized platform, ideal for placement and alignment of surface-mount components on the pc boards. It is equipped with advanced machine frameworks powered by high-tech motors to enhance the process accuracy and efficiency. It offers a simple and intuitive mechanical design with repeatable accuracy, ensuring a reliable delivery of high-quality finished products. To start the pc board assembly process, JUKI KE 2050L pc board is loaded into the machine using its intelligent positioning system. This unit automatically detects the position of the board and provides correct placement of components on the board. The automatic component placement process is powered by innovative motion-based pick-and-place machines. These machines accurately place each component with each layer in their corresponding slots on the board. ZEVATECH KE 2050L is also equipped with an advanced ionizer station that uses ionized air to mitigate Electrostatic Discharge (ESD). This feature prevents any damage to the board due to static build-up. Additionally, the machine also offers mechanical soldering, machine-level control and machine level software monitoring. The machine has a wide range of features that ensure quality control for the assembly process. It has advanced audit/verification systems that help detect faulty components or sub-assemblies. Additionally, it has in-built multiple vision systems that help to check the accuracy and reliability of the assembly process. KE 2050L pc board assembly and manufacturing machine is an all-in-one package for fast, accurate assembly and manufacture of pc boards. It is simple to use, highly efficient and designed to reduce assembly times and enhance production processes. Overall, it provides cost-efficient solutions that improve the overall performance and reliability of the production process.

There are no reviews yet