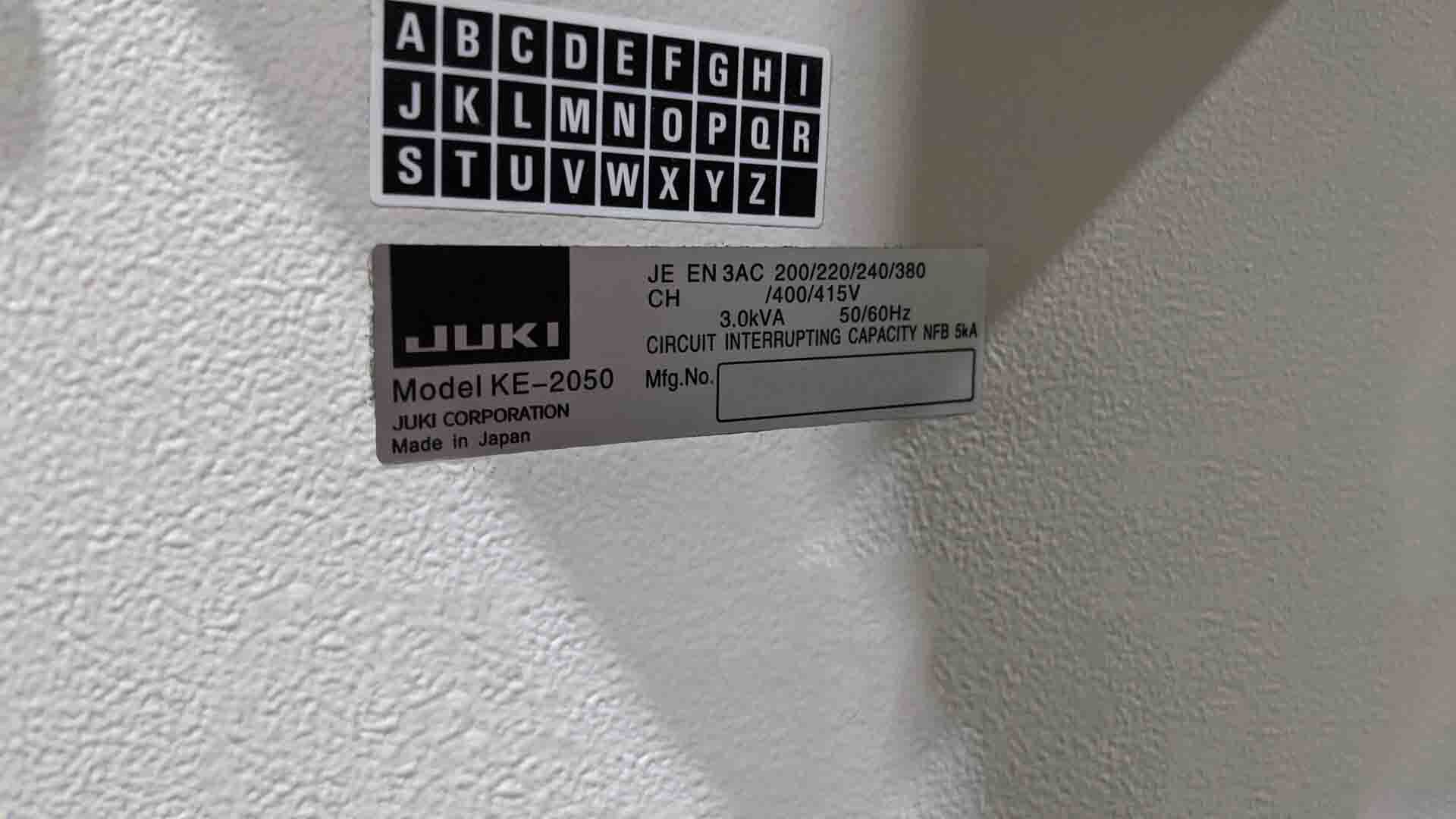

Used ZEVATECH / JUKI KE 2050M #293603847 for sale

URL successfully copied!

Tap to zoom

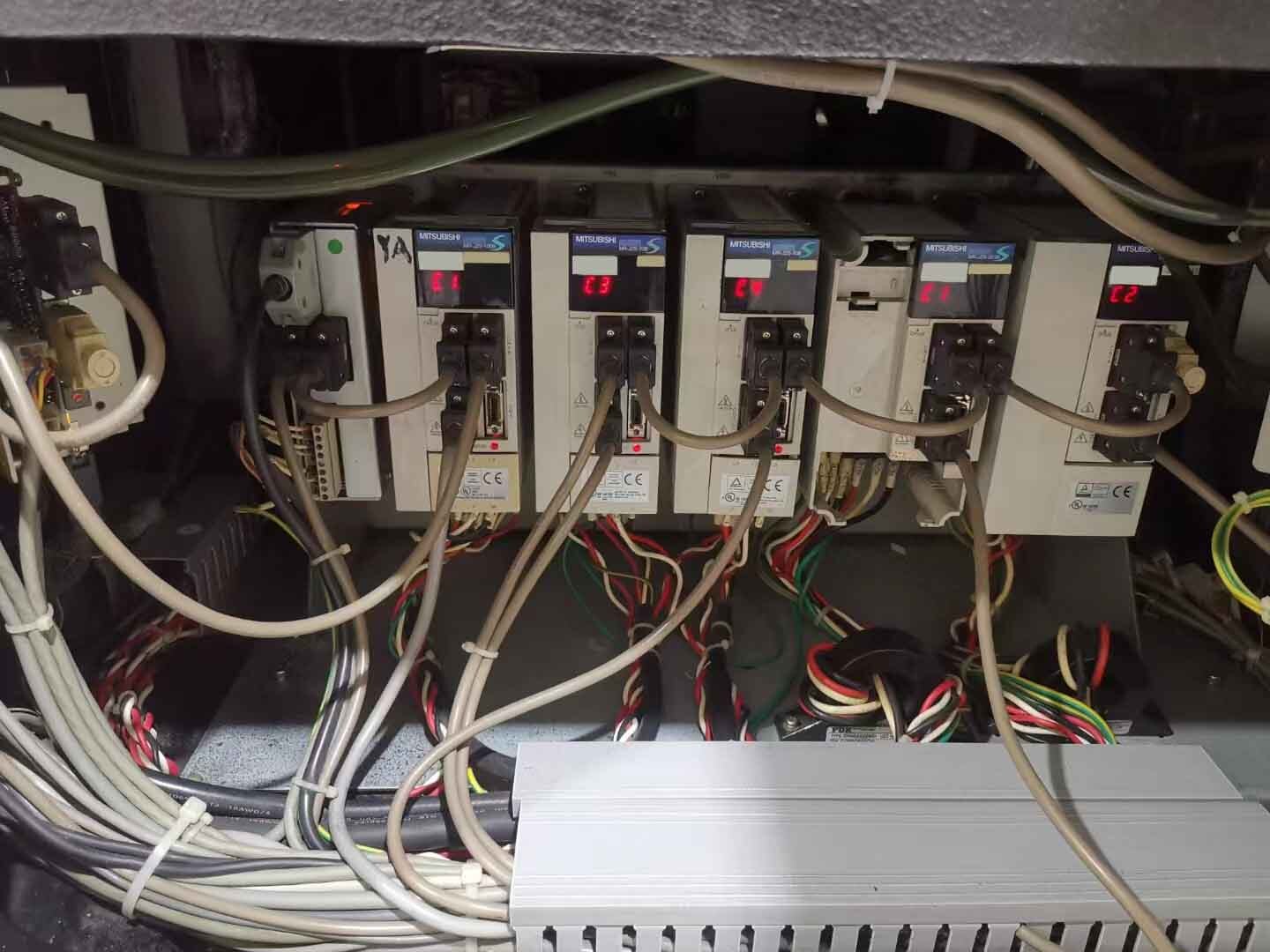

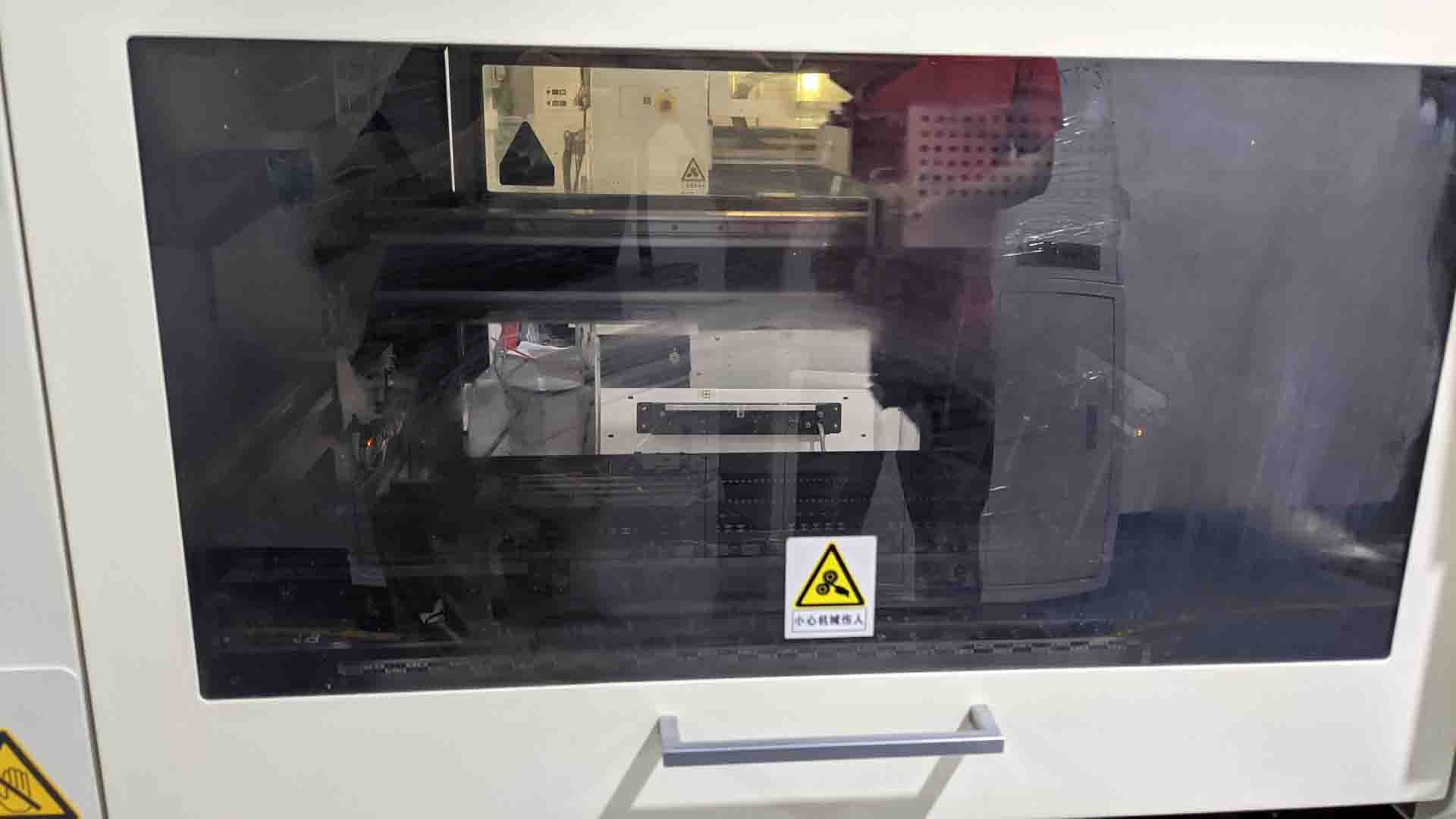

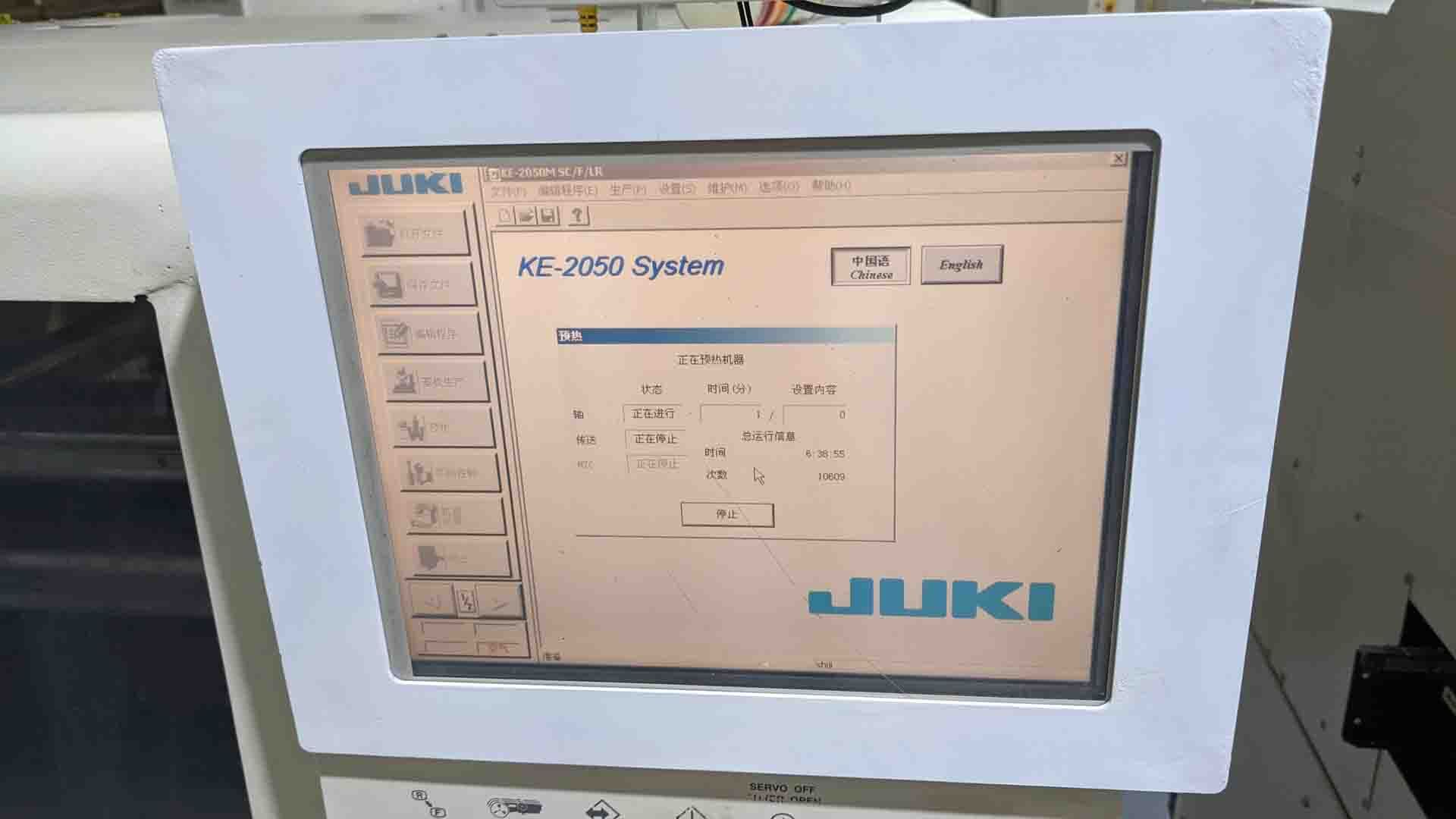

ZEVATECH / JUKI KE 2050M is a pc board assembly and manufacturing equipment that is designed to be a complete solution for the entire process of printed circuit board assembly. It offers multi-zone heating and cooling capabilities, laser direct imaging, robot loading, and a variety of automatic vision inspection systems. It can be used for both high-volume and low-volume production operations. JUKI KE 2050M system is equipped with a powerful conveyor unit. It has a maximum conveyor speed of 4.5 m/s and a maximum pallet size of 76 by 76 centimeters (cm). It also comes with a dyno-matic engine, which allows for precise and rapid control over the operation of the machine. The tool is powered by a powerful PLC that includes powerful digital and analog controls that facilitate the automated control of the entire assembly process. It is also integrated with a variety of interfaces that enable connection to other systems and software. The asset features multi-zone heating and cooling capabilities. A variety of infrared and air-bath-based systems are available for pre-heating, thermal profile inspection and cooling the pc boards. These systems use the latest technology and reliable high-pressure model that can reduce the impacts of changing temperature levels. ZEVATECH KE 2050M equipment also includes laser direct imaging. This is a process of programming of the pc boards, wherein lasers are used to write high-resolution graphics onto the board surface. This allows for accurate placement of components and labels, as well as complex patterns, which enhances accuracy and yields higher-quality pc boards. Additionally, the system comes with robot loading. Robot loading allows for the automation of loading parts onto the pc boards. The robots can be programmed to identify and place parts accurately and quickly. This can reduce the amount of labor time involved in the assembly and manufacturing process. Finally, KE 2050M unit includes a variety of automatic vision inspection systems. This allows for automated checking for errors, defects and damages in pc boards. This will help ensure adherence to standards of quality and also reduce the turnaround times for pc board assembly. All in all, ZEVATECH / JUKI KE 2050M machine is a complete solution for pc board assembly and manufacturing. It is equipped with the latest technology and powerful features, which make it well-suited for both high-volume production and low-volume operations. The features of the tool ensure accurate placement of components and labels, as well as fast turnaround times and high standards of quality in pc board assembly.

There are no reviews yet