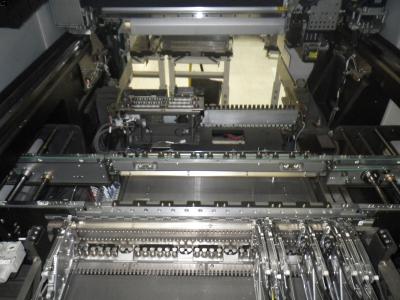

Used ZEVATECH / JUKI KE 2050RL #9129068 for sale

URL successfully copied!

Tap to zoom

ID: 9129068

Vintage: 2007

Pick and place machine,

L size conveyor

Hours: 3000

Software: 1.20B

(4)One multi nozzle laser head

vision centering system

Tri-directional lighting

Board fiducial offset correction

Auto nozzle change station

Board edge clamping system

(2) Micron linear encoders

Bad mark reading via OCC

Touch screen panel

0201 capable to 20mm square chip

2007 vintage.

ZEVATECH / JUKI KE 2050RL is a high-speed, fine-pitch pc board assembly and manufacturing equipment. It features an intuitive, easy-to-use operation interface with software friendly environment and high data handling capacity. The system is ideal for high-volume PCB production runs and its intelligent management unit ensures efficient production flows and enhanced product quality. The machine is equipped with an advanced processing unit that is versatile to various PCB types and specifications. The micro-processing unit provides a high degree of accuracy and precision when implementing the allocated jobs. Its advanced vision tool recognizes component types and adjusts the vision asset parameters accordingly for best performance and yield. The model is equipped with a dual-gantry and dual-nozzle design that eliminates the need for recalibration between different job operations. The gantry design eliminates the need for multiple lines of operation in the same cell, thereby reducing the idle time and improving throughput. The equipment also includes a universal stencil printer with high speed capabilities, used to apply solder paste onto the board exactly where needed. The system includes a variety of feeder options like intelligent JUKI multi-tooled feeder unit, split-feeders, and tray-feeders that allow various reels and tray sizes. The intelligent ZEVATECH multi-tooled feeder machine provides smart feeder technology and assists in speedy changeover between jobs and accuracy over the width of the PCB. The built-in process support tool software integrates the design, manufacture, testing, maintenance and management. It offers full-time assistance and documents production process, process capability, yield, maintenance and troubleshooting. The included Quality Management Asset features powerful traceability model and Quality Plan Database that records the quality of components and manufacturing process. With its robots and pick & place modules connected through Ethernet, the equipment manages flexible job setup, efficient production and better product quality. The built-in SMEMA interface is compatible with various robots. The system also supports multiple languages and new software updates. All in all, JUKI KE 2050RL is an industrial pc board assembly and manufacturing unit designed to provide high performance and maximum efficiency. With its advanced features, it enables quick and precise assembly and offers a streamlined production workflow.

There are no reviews yet