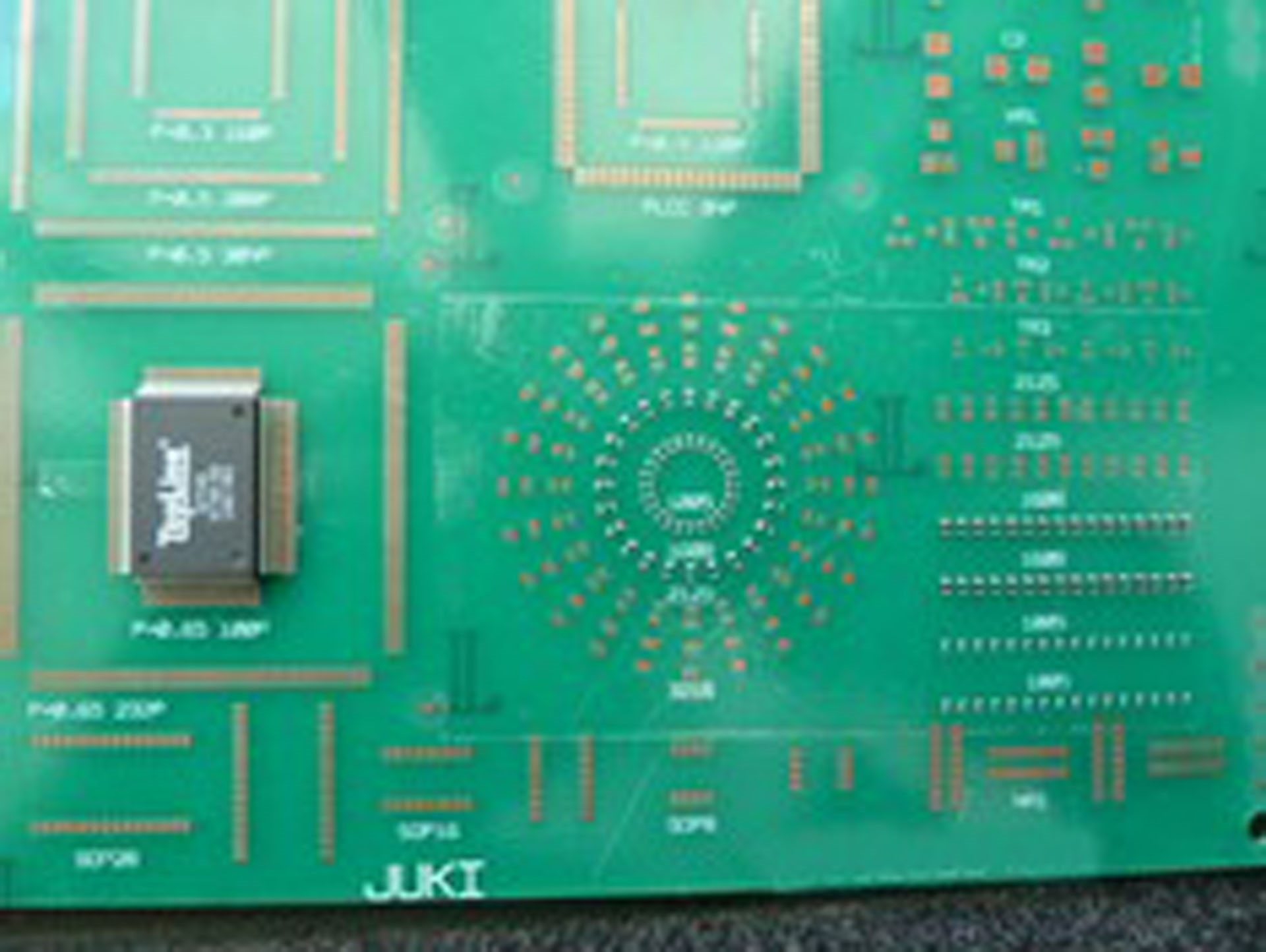

Used ZEVATECH / JUKI KE 2055RM #9258936 for sale

URL successfully copied!

Tap to zoom

ID: 9258936

Vintage: 2007

Chip mounter

Flow direction: Left to right (Front fixed)

PCB Size: 330 mm × 250 mm

Tact:

12,500 CPH for chip

3,290 CPH for IC

(40) Carriable parts in 8 mm

QFP Tray

Multi laser head with (4) nozzles

High resolution vision head with nozzle

Feeder changing cart type: Front side

Fixed feeder bank type: Rear side

MNVC (Multi Nozzle Vision Centering)

HMS (Height Measurement System)

Feeder changing cart per unit for front side

(20) Feeders

Manual tray

2007 vintage.

ZEVATECH / JUKI KE 2055RM is a PC board assembly and manufacturing equipment purpose-built to meet the high-volume production requirements of demanding electronic product manufacturers. This system offers superior speed and accuracy, allowing manufacturers to produce more high-quality products quicker than ever before. JUKI KE 2055RM is based on a modular design concept that allows for quick and easy unit configuration. The machine comprises several key components, including a controller, a feeder, multiple placement heads, and a conveyor. The tool's controller is designed to be highly intuitive and user-friendly. It offers a variety of features such as a graphical program builder and built-in diagnostic tools to make setup of the asset easier and faster. The controller runs on Windows operating model, providing users with a familiar working environment. The equipment's feeder is designed to meet the requirements of high-speed production. This feeder provides a stable, secure platform for the components to be placed properly. It can handle a wide range of components, such as ICs, resistors, capacitors, and transistors. The feeder also has an adjustable auto-feed speed to manage component flow during high-speed operation. The system's multiple placement heads offer both speed and precision. These precision heads are designed to provide consistently precise results, even during periods of high-speed operation. The placement heads can handle a wide range of components, from small 0402 components to large 0.75" parts. They also provide off-the-shelf vision alignment capabilities for precise identification and placement of components on the PC board. The unit's conveyor is designed for maximum efficiency and reliability. It features high-speed motion control, as well as adjustable speeds and timing for precise manufacturing processes. The conveyor is capable of handling several constraint PC boards simultaneously, allowing for the fast and accurate production of large volumes of PC boards. Overall, ZEVATECH KE 2055RM is a high-tech PC board assembly and manufacturing machine that offers superior performance, speed, and accuracy. It is designed to meet the rigorous requirements of electronic product manufacturing operations, allowing the high-volume production of quality PC boards.

There are no reviews yet