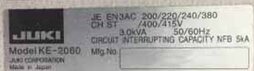

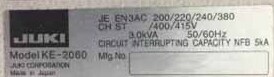

Used ZEVATECH / JUKI KE 2060 #9352396 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2060 from JUKI is an advanced PC Board assembly and manufacturing equipment that combines innovative dual gantry system architecture with extensive automation technology. The advanced dual gantry unit provides efficient and accurate motion of the mounted modular head to different process areas. This machine offers high performance at a competitive price and helps users to continuously improve their manufacturing process by increasing process accuracy and throughput. JUKI KE 2060 is a highly advanced tool with a dual gantry asset with a modular head which increases the overall efficiency of the model while reducing maintenance costs. This advanced design allows for higher accuracy motion of the mounted head and provides accurate placement of the components to the board. It features a large closed loop controlled pick and place head with a repeatability of ±0.003", offering optimal performance with extremely fine pitch components. The automated equipment is capable of providing up to 20,000CPH of placement with extremely fine pitch components, such as BGAs, QFPs, and 01005s. It also incorporates an auto-section teaching system which facilitates easy program editing, including tool-less access to the parts tray unit, to reduce setup times. The PC Board assembly and manufacturing machine of ZEVATECH KE2060 is equipped with advanced vision technologies for inspection and verification which enables the tool to inspect a variety of board and component conditions. These technologies help to ensure a high level of quality control with a high yield rate. It also features dynamic inspection capabilities with surface mount LED inspection, bottom camera inspection and one- and two-dimensional probe assembly inspection to accurately inspect and verify surface-mounting accuracy, mounting conditions, and polarity of components. The asset also offers a range of control features, such as on-board process control, real-time data processing and management, and multiple process control methods. It provides users with access to detailed process data, allowing users to trace errors in the model and to identify areas where improvements can be made. Additionally, the equipment can be integrated with ERP and other third-party applications to enable easy machine monitoring and data tracking. JUKI KE2060 is a cost-effective, reliable, and efficient PC Board assembly and manufacturing system from ZEVATECH. It has a range of advanced features such as dual gantry unit, automated part tray machine, dynamic inspection capabilities, and on-board process control, allowing users to manufacture high-quality boards with maximum efficiency and reliability.

There are no reviews yet