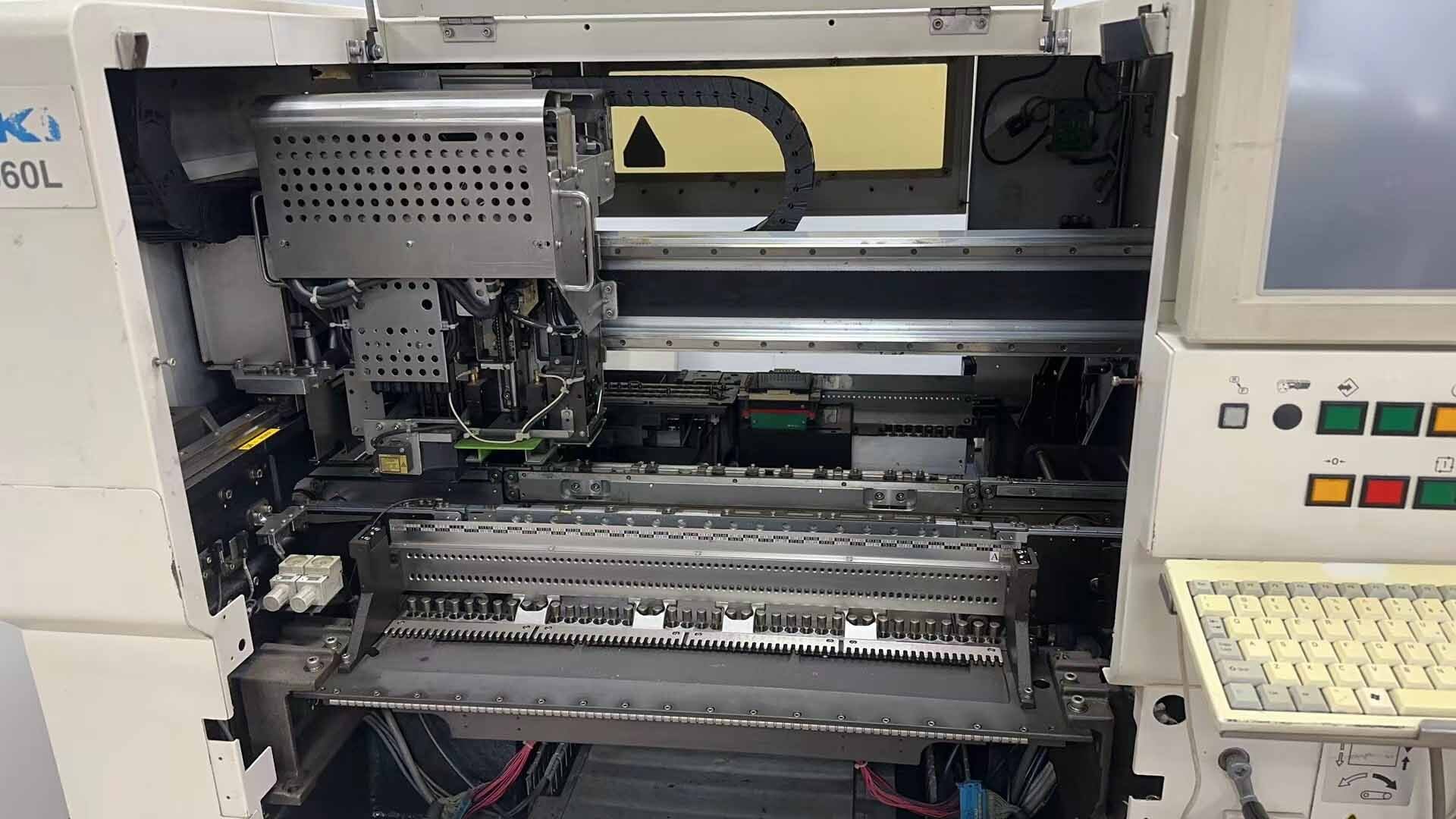

Used ZEVATECH / JUKI KE 2060L #293643475 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2060L is a high-volume, high-precision, automated PC board assembly and manufacturing equipment that offers an optimal solution for any production line or laboratory. This system offers a compact, flexible, and easy-to-use platform that packs a powerful punch when it comes to overall speed, accuracy and performance. JUKI KE 2060L features a modern design with a large workspace, allowing for faster and easier assembly of components effectively and reliably. Additionally, the integrated board clamping unit allows for secure fixing of any board size. ZEVATECH KE 2060L utilizes a powerful dual-head pick-and-place head that enables simultaneous operation of two components and the machine can be mounted with either the end-arm style gripper mechanism or the wing-tip style gripper for versatile grip shapes. This pick-and-place tool allows for a wide variety of parts and components to be efficiently placed and integrated into the board, rapidly and with high accuracy. In addition, KE 2060L operates with a CCD camera asset featuring image processing for reading and scanning bare boards. Reversed parts along with cracks in the solder joints can also be detected by this model, making for an error-free and reliable production process. ZEVATECH / JUKI KE 2060L integrated software offers quick operation and set-up, allowing users to make adjustments and screen settings during the production process. The software also has a simple desktop interfacing, while a full graphic-oriented programming package enables fast programming. The line is modular, providing the operator with flexibility to use the equipment as needed. In addition, the system is compatible with SIPLACE, a Workstation Operating Unit (WOS) that can be used to control several functions such as diagnostics, connection of remotely located machines and software updates. JUKI KE 2060L features 15 nozzles and 4 feeders, automatic tool changing and a 4-stage sorter for feeding boards in order for sequentially assembling them. The top-view camera and the flexible truck machine ensure that there is no need for manual positioning when loading and unloading PCBs. The board movement mechanism comprises a dual-track synchronized conveyor tool, providing for error-free assembly by eliminating errors associated with travel. Furthermore, the asset can effortlessly reach a maximum production rate of 1000 CPH (contacts per hour) and contains a total of 16 motor driven axes to maximize speed and accuracy. All in all, ZEVATECH KE 2060L is an advanced and versatile automation solution capable of working at the highest levels of speed, accuracy and performance. Its features, design and components make it the perfect choice for any PC board assembly or manufacturing process, giving users a highly efficient and reliable production platform that can meet the demands of any industry.

There are no reviews yet