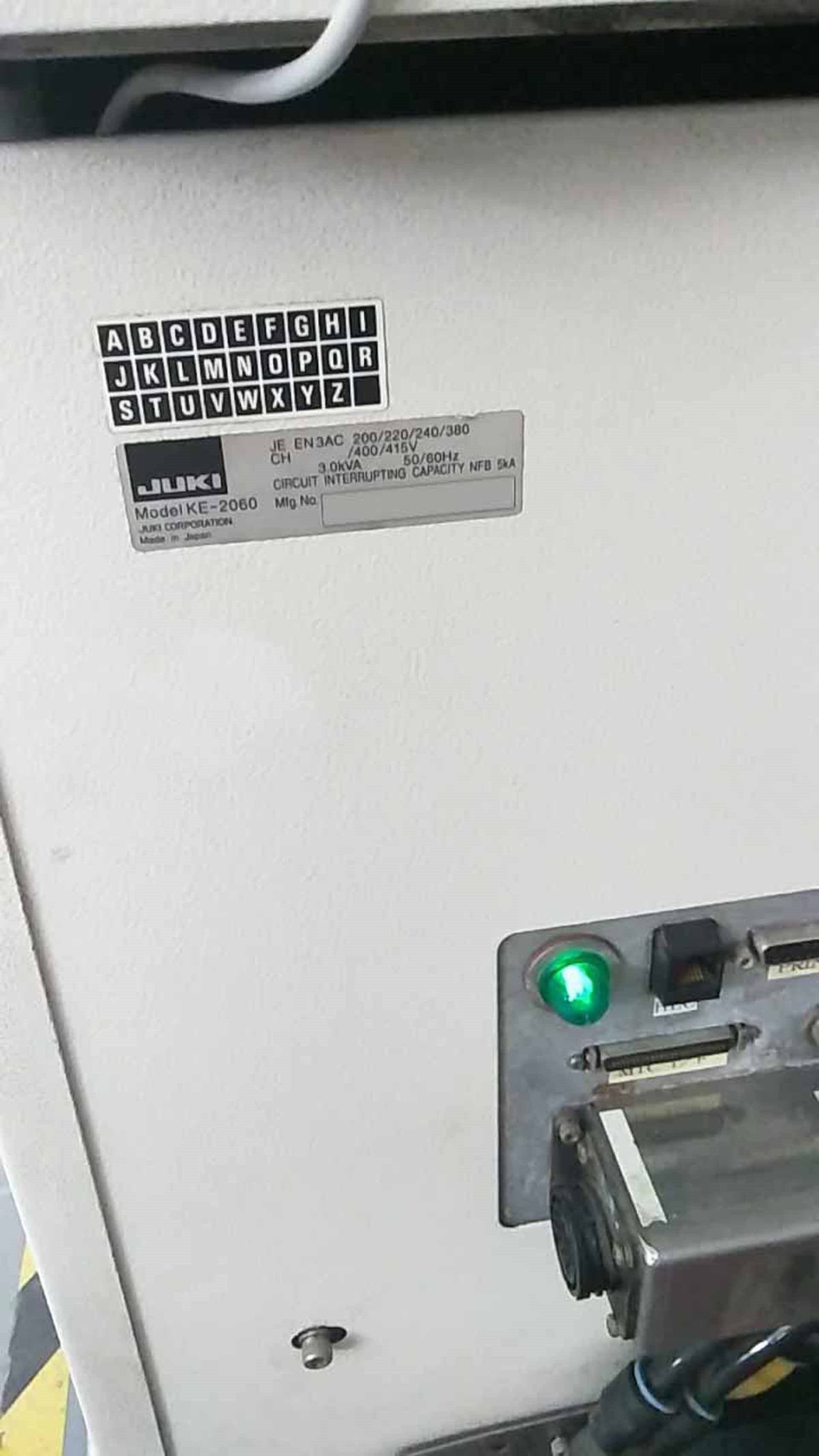

Used ZEVATECH / JUKI KE 2060L #9230262 for sale

URL successfully copied!

Tap to zoom

ID: 9230262

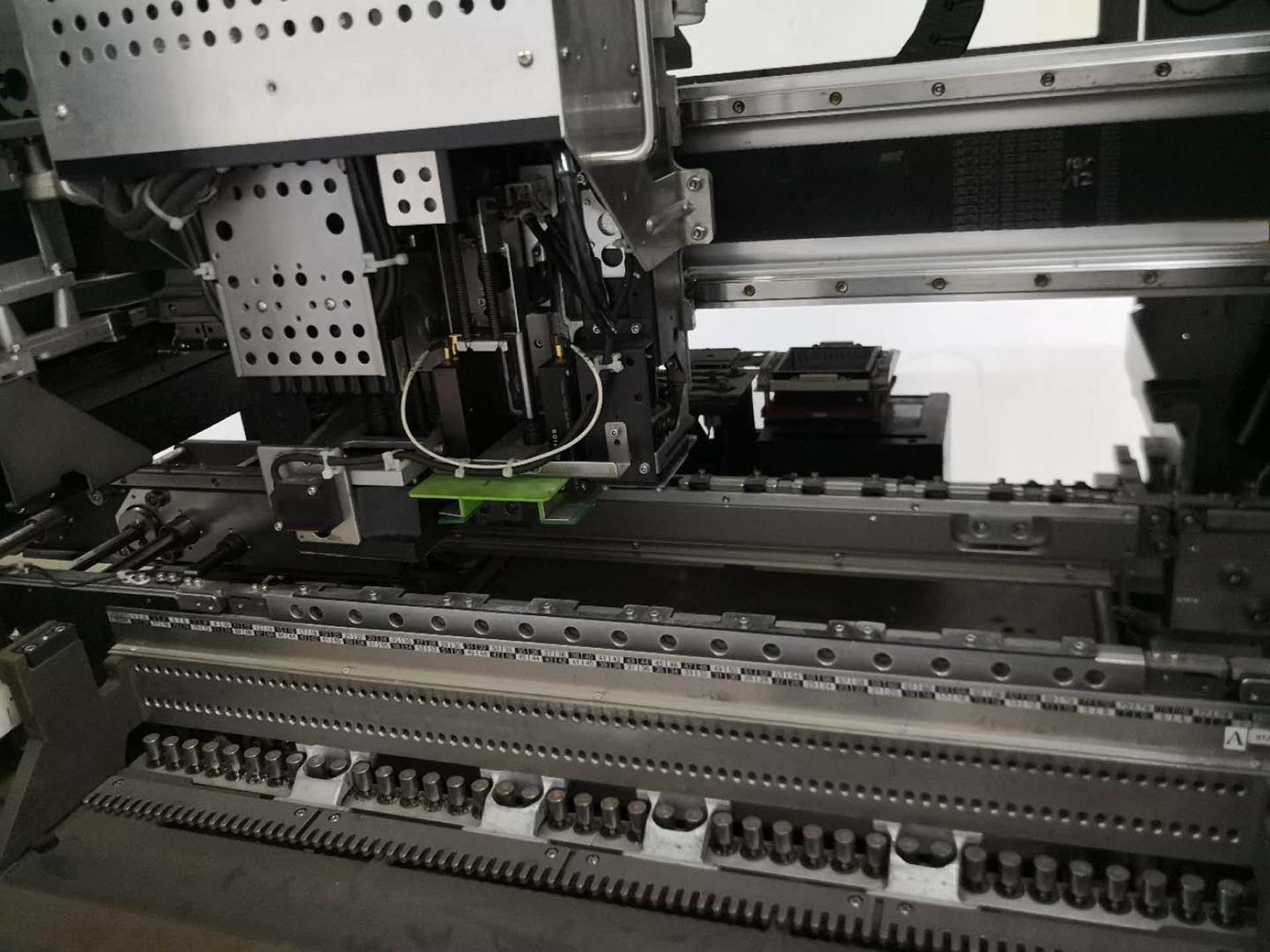

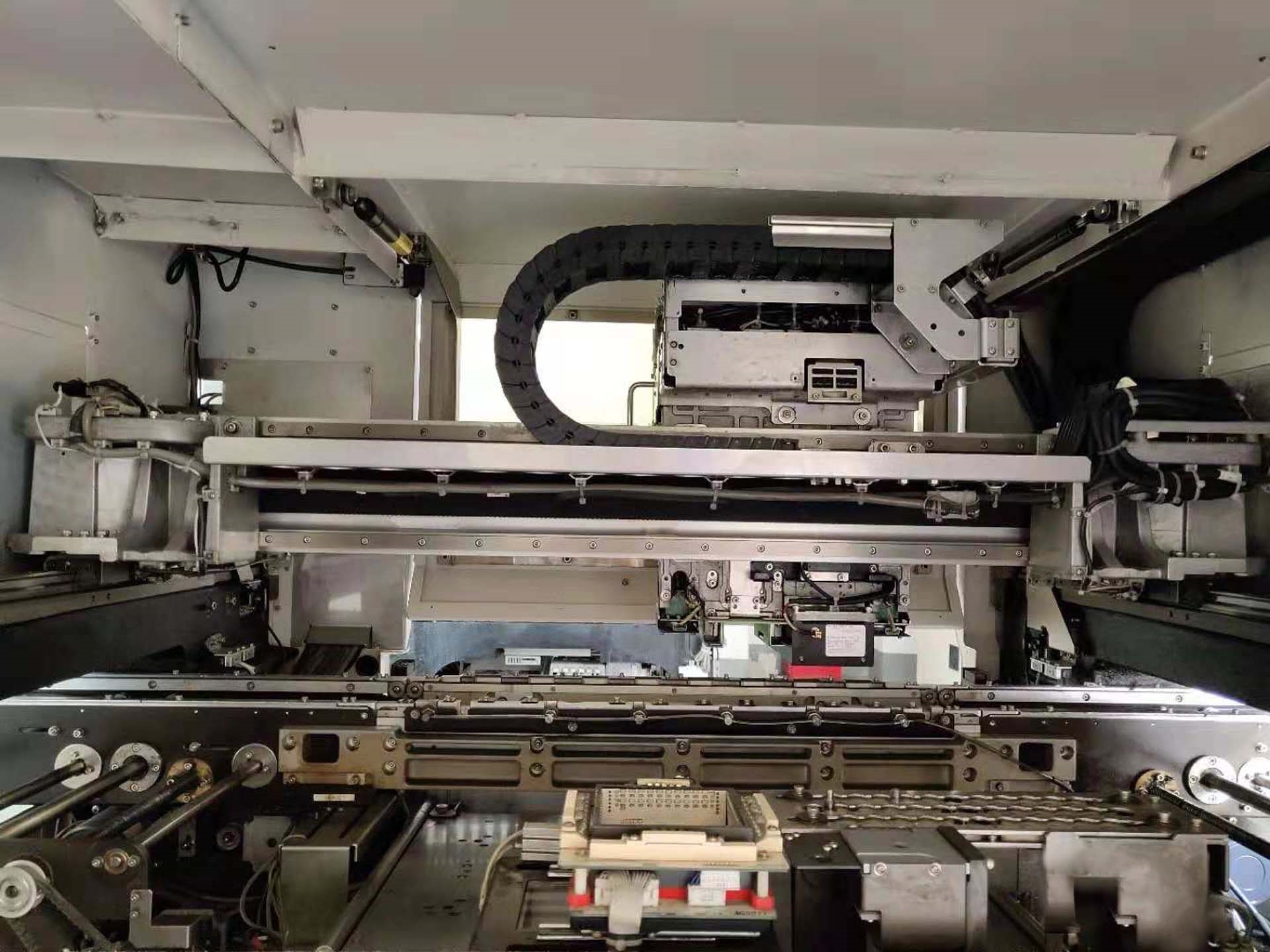

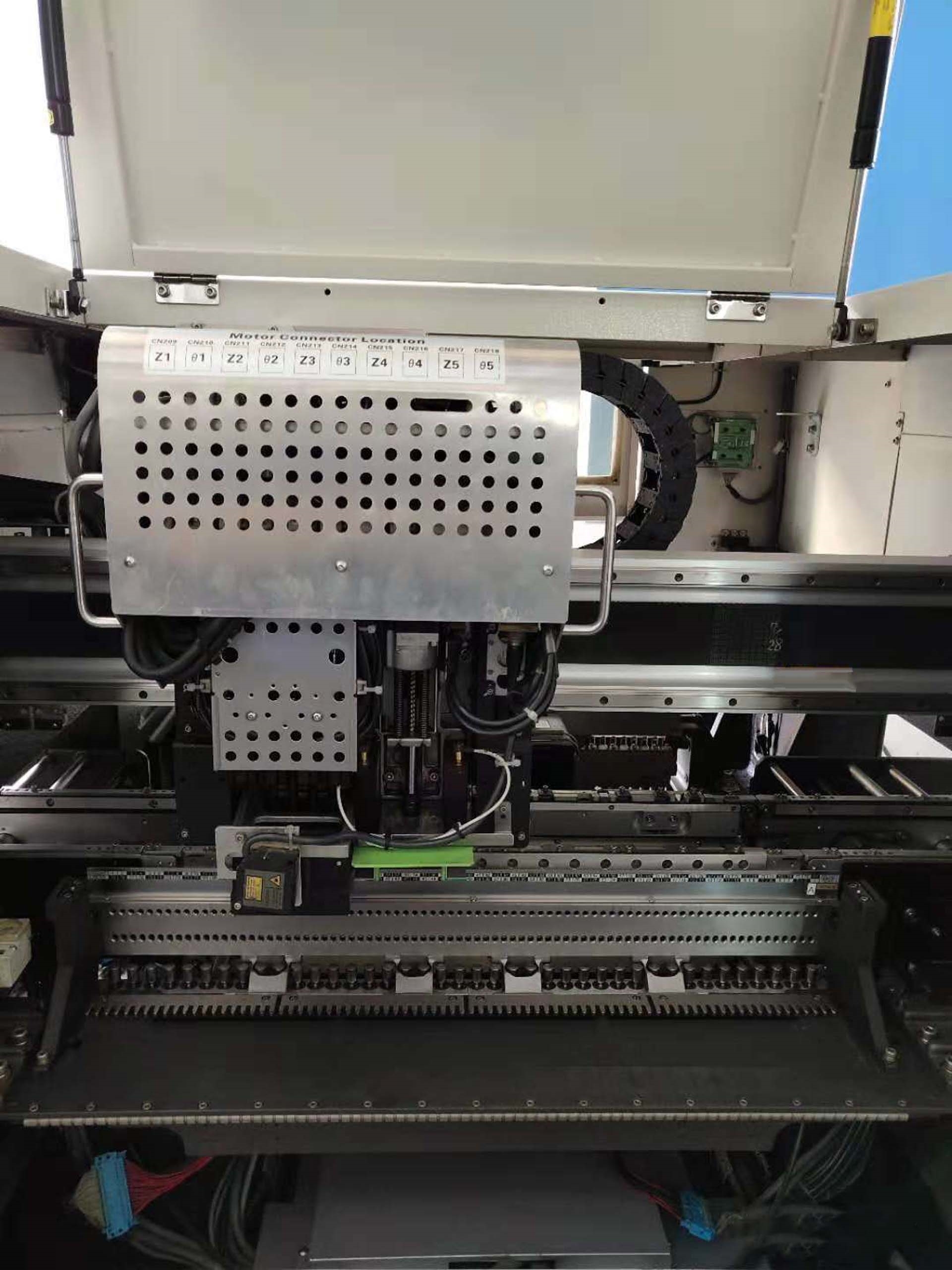

Chip mounter

Matrix tray changer

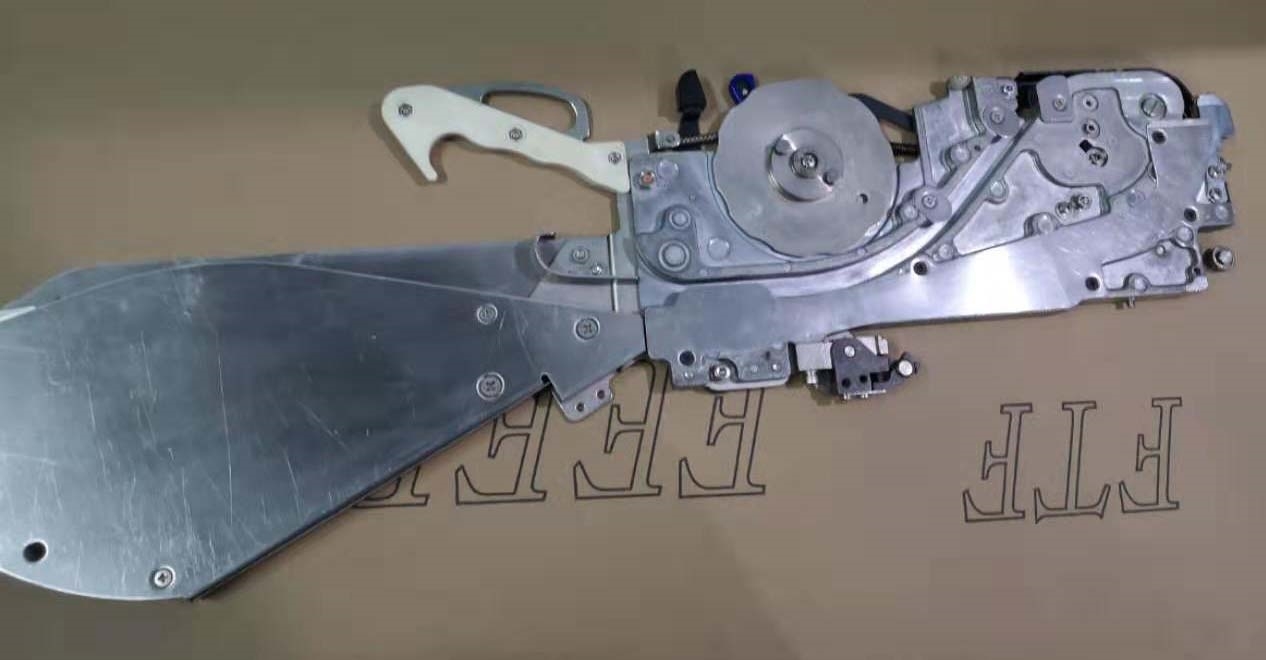

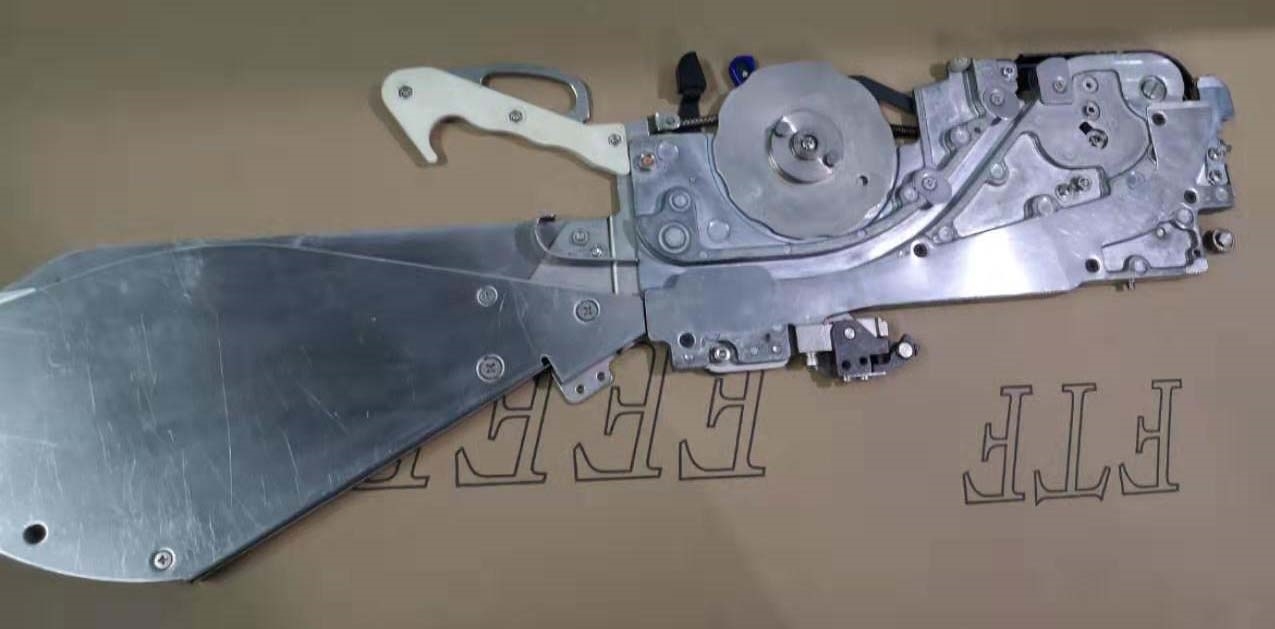

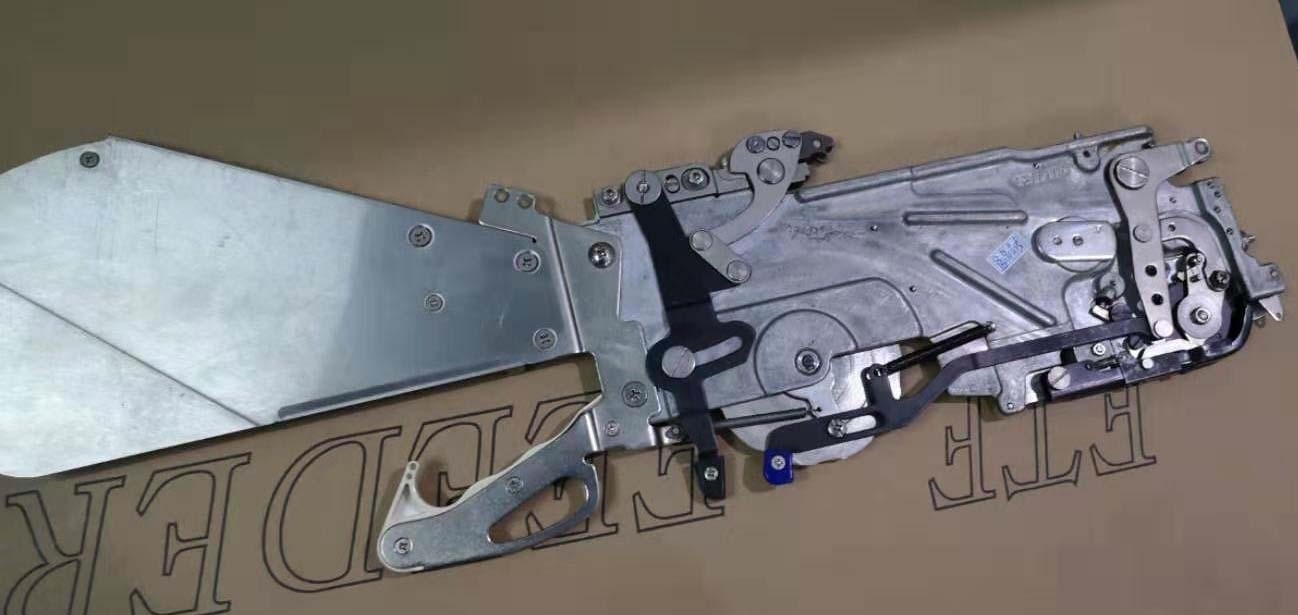

Feeders:

Qty / Type / Size

(60) / CF / 8 mm

(21) / NF / 12 mm

(9) / NF / 16 mm

(5) / NF / 24 mm

(2) / NF / 32 mm

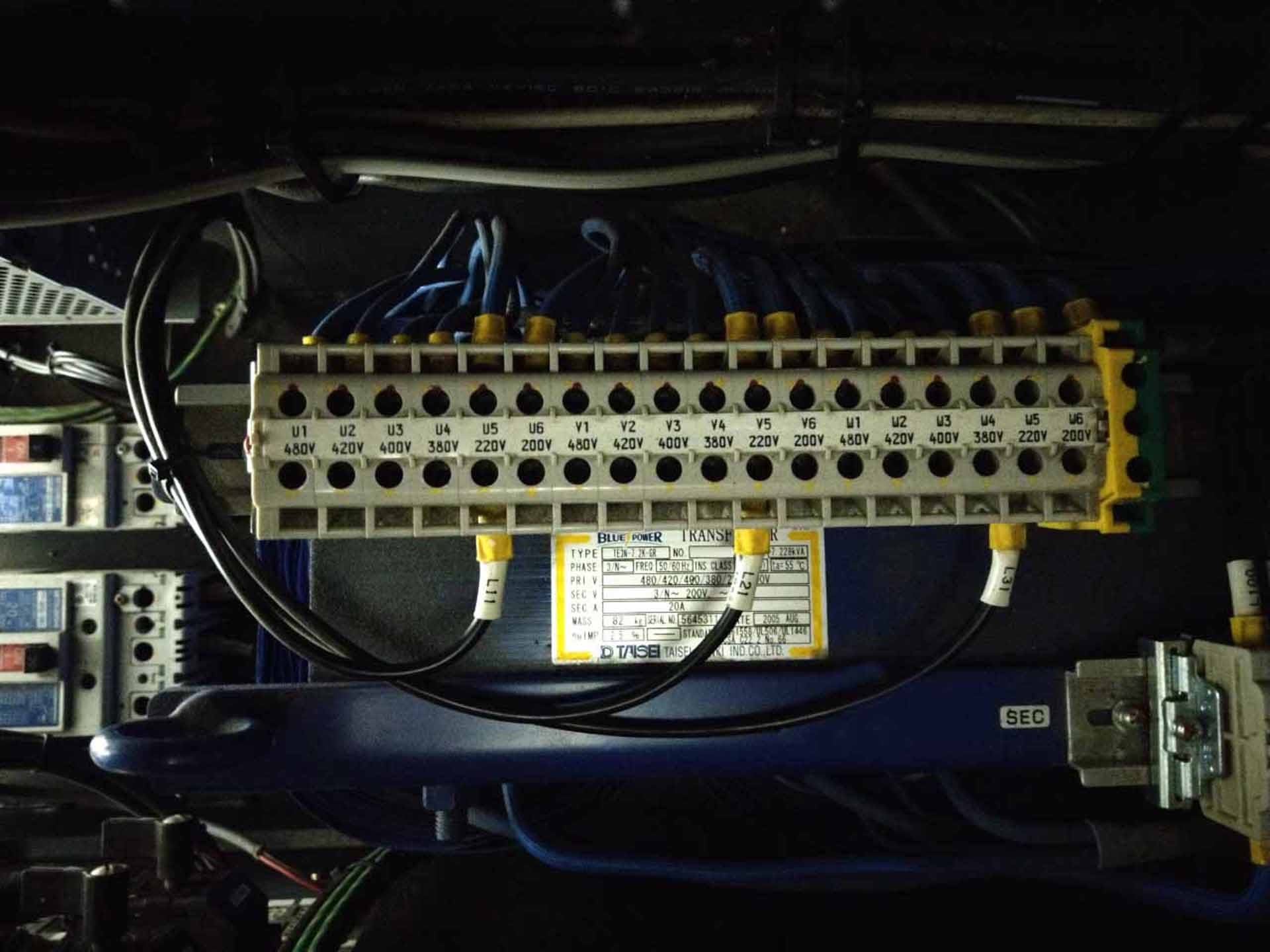

Power: 200 V / 220 V / 240 V / 380 V / 400 V / 415 V

Does not include nozzles

2005-2006 vintage.

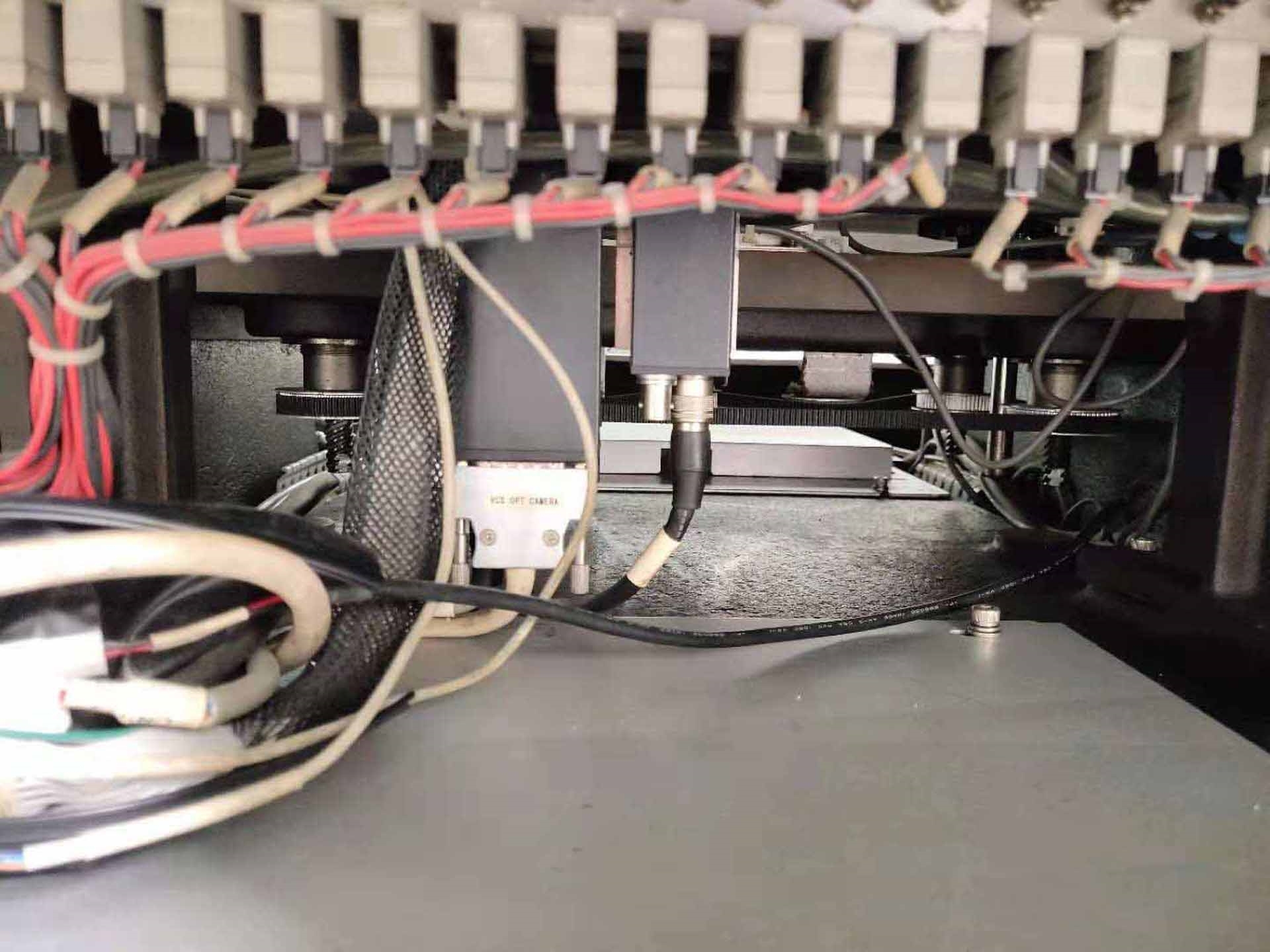

ZEVATECH / JUKI KE 2060L is a PC board assembly and manufacturing equipment designed to meet a wide range of production needs. This system features an intuitive user interface, advanced process control, and straightforward process engineering. JUKI KE 2060L offers superior equipment performance, allowing for high volume production with maximum efficiency and quality assurance. The unit is outfitted with a range of components designed to streamline the PCB assembly process. The machine features a placement head, a vacuum table for holding the PCB, an X/Y table to position the components to be placed, and a vision tool with CCD cameras to check placement accuracy. Additionally, the asset is equipped with a solder pot, a fluxer, a cleaning station, and a board-to-board transfer model. ZEVATECH KE 2060L's placement head utilizes a vision-guided, multi-function mechanical alignment equipment which ensures accurate component placement and repeatable results. This system also incorporates a high speed "shuffle" technology, which helps to minimize cycle times and ensure a high-quality end product. Further, the unit's X/Y table includes an integrated vacuum transport machine, allowing for flexible component placement. The vision tool plays an important role in KE 2060L's process control, providing intelligent feedback that helps ensure high levels of accuracy and consistency. By using image guidance, the vision asset can detect incorrect component placement and generate an alarm for correction. The vision model can also be used to check that all solder joints are correctly formed and free of defects. Other important features of ZEVATECH / JUKI KE 2060L include its integrated cleaning equipment, which can remove flux residues and other contaminants from the resultant PCBs. The cleaning system utilizes an advanced fluid grouping technology, which allows it to be used in a variety of processes, including stencil cleaning, fluxless and fluxed soldering, and after-solder cleaning. Additionally, JUKI KE 2060L is equipped with a fluxer and a solder pot, allowing operators to quickly complete soldering tasks with precision and accuracy. ZEVATECH KE 2060L PC board assembly and manufacturing unit is an excellent choice for a wide range of production needs. Its intuitive user interface, advanced process control, and straightforward process engineering make it an ideal choice for anyone looking to achieve high quality results with maximum efficiency.

There are no reviews yet