Used ZEVATECH / JUKI KE 2060L #9252892 for sale

URL successfully copied!

Tap to zoom

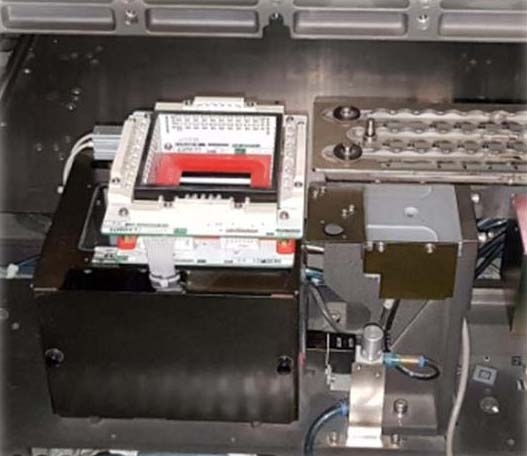

ZEVATECH / JUKI KE 2060L is a programmable, highly versatile and configurable, automated PC Board assembly and manufacturing equipment. It is designed to provide maximum flexibility and throughput in various manufacturing environments from low to medium-volume production of Printed Circuit Boards (PCBs). The system is based on a modular structure consisting of an input, a programming, and a placement unit. The input machine is where the component parts are provided to JUKI KE 2060L tool. It is capable of accepting components delivered in reel tapes, loose parts, trays, or can support automatic pick and place robots. The built-in programming station allows for fast and accurate programming of the component positions directly on the Printed Circuit Board. The programming asset contains an intuitive consumer-friendly touch screen interface and powerful machine software that operationalizes the programming process. This model can be customized to match the customer's needs and offers the capability of programming multiple Printed Circuit Boards simultaneously. The placement equipment is the main feature of ZEVATECH KE 2060L. It operates with precision accuracy in placing components at any measured location on the Printed Circuit Board. Highly integrated tooling systems are included for optimal performance and can reduce setup times compared to other solder-resistant tools. The programming interface makes it easy to place components correctly and accurately with minimal reprogramming required when changing components. Furthermore, the system includes additional features such as integrated climate control, dual vacuum pumps, and a range of optional nozzle styles. KE 2060L unit can be further expanded with the optional placement board feeders and the built-in inspection machine. The combination of these various features ensure accurate, quick and reliable assembly of Printed Circuit Boards. In conclusion, ZEVATECH / JUKI KE 2060L PC Board assembly and manufacturing tool represents the latest technology in automated assembly and placement of Printed Circuit Boards. It is a powerful machine that combines programming, placement and tooling efficiency for maximum flexibility and performance. The asset provides reliable and fast assembly and placement of components at any measured location on the printed circuit board. It offers cost-effective and efficient solutions to expand production levels in a wide range of applications.

There are no reviews yet