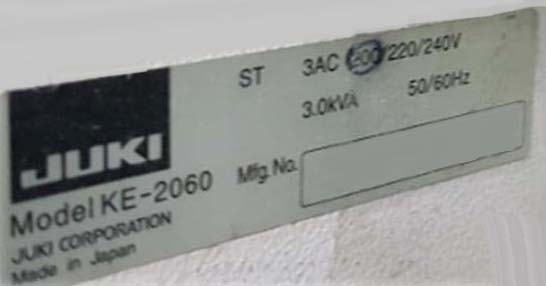

Used ZEVATECH / JUKI KE 2060L #9252893 for sale

URL successfully copied!

Tap to zoom

ID: 9252893

Vintage: 2006

Chip mounters

With tray magazine

(223) Mixed feeders

2006 vintage.

ZEVATECH / JUKI KE 2060L is a high-performance, multi-function PC board assembly and manufacturing equipment designed for medium to high volume component placement operations. It is equipped with an advanced motion control system that helps to improve placement accuracy while reducing cycle times. The unit features a dual gantry design with four high-precision linear stages, providing fast, accurate placement of small and large components over an extended working area. With a working area of 790 x 390 mm and repeatability of ±0.04 mm, JUKI KE 2060L is capable of placing 0402 chip components up to 8 mm² in size with single motion placement accuracy of ±0.08 mm. The machine's advanced vision tool offers true 3D vision recognition combined with advanced algorithms to detect defects and placement accuracy at high speed. The 8-point vision correction tool helps maintain placement accuracy over time. The rigid gantry asset also reduces vibration levels, ensuring minimal nozzle change cycle times. ZEVATECH KE 2060L can also accommodate a large range of feeders, including double-faced, multi-stage, and JEDEC tray, and compatible tray types. KE 2060L also offers an intuitive user interface and multiple programming options for easy setup and operation. The high-resolution, colour LCD touch panel offers easy-to-understand setup screens with helpful indicators. Flexible programming is available via fine pitch JBO Direct with a variety of language choices including English, Japanese, and Chinese. The model also supports panel IDs for flexible operation in various production environments. In conclusion, ZEVATECH / JUKI KE 2060L is an advanced, multi-function PC board assembly and manufacturing equipment designed for medium to high volume component placement operations. It offers an impressive range of features for accurate, efficient placement, including a dual gantry design, 8-point vision correction tool, intuitive user interface and multiple programming options. It is capable of placing 0402 chip components up to 8 mm² in size with single motion placement accuracy of ±0.08 mm, making it an ideal choice for any production environment.

There are no reviews yet