Used ZEVATECH / JUKI KE 2060M #293605483 for sale

URL successfully copied!

Tap to zoom

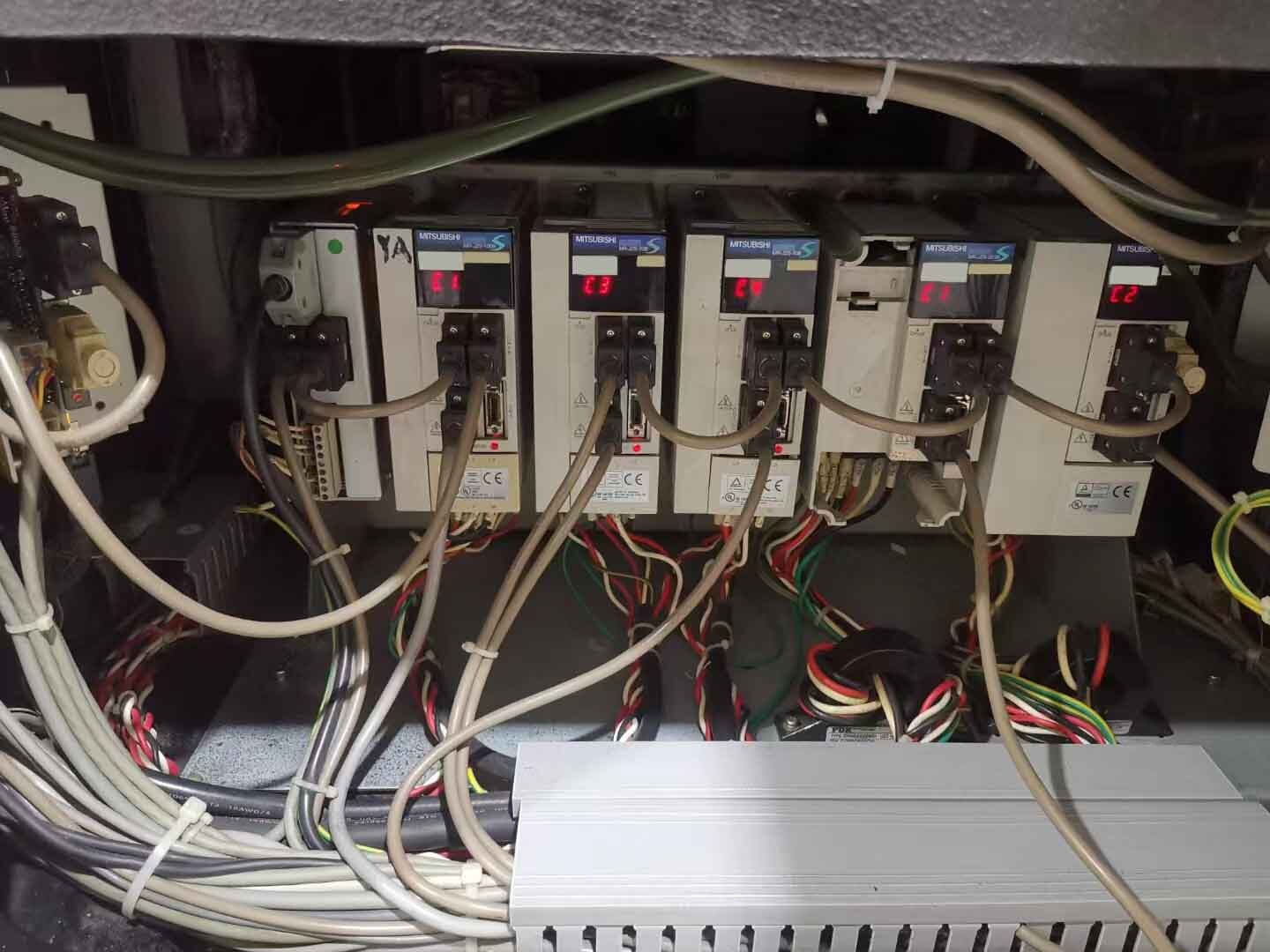

ZEVATECH / JUKI KE 2060M is a fully automated PC Board Assembly and Manufacturing equipment shouldered with a vast array of advanced features. It meets the production requirements for any type of electronics product with reliability, flexibility and high accuracy for the end user. JUKI KE 2060M features a concept of modular design offering maximum configuration & flexibility. This allows for quick and easy customization to fit your changing business needs. The system includes a 200mm x 260mm solder paste printer, fine pitch placement head with 20 microns accuracy, 4 nozzles, a high-speed 80K/hr top/bottom module, and an 8 nozzle HI-SPEED Multipurpose placement head. In addition, an intelligent integrated vision unit provides an automated high-quality inspection machine with noteworthy accuracy and speed. The fabricator on ZEVATECH KE 2060M is equipped with a 0201 schematic library that digitally stores each component's characteristic profile, accounting for its size, shape, height, and electrical characteristics. This enables the tool to execute exceptionally accurate placements and allow for real-time management. The board handling asset extracts boards automatically. Then the feeder life check on the board all within the same cell. The model also features an advanced and integrated conveyor architecture with multiple functions. The conveyor incorporates sophisticated lane control with no setup/switchover at all, allowing for increased efficiency from step to step. KE 2060M is further equipped with a robotic arm that allows easy-of-use and access to the product from multiple angles. This ensures high-sensitivity assembly, quick and convenient loading, and rapid threading. The built-in vacuum station is used for additional adhesive material operations. Other features include a vacuum tape pickup equipment for tapes and a wooden pallet handling conveyor for reel to reel operations. To keep up with production demand, ZEVATECH / JUKI KE 2060M is designed to handle up to 40 feeder stations and up to 160 feeders. This is accompanied with a multi-tune functionality, that is able to optimize production time while ensuring quality in all processes. Furthermore, an optional bar-code reader ensures traceability to create an accurate unit history. The system's user-friendly interface allows automated and manual creation of programs with easy access to parts data and libraries. In summary, JUKI KE 2060M's comprehensive array of features and advanced technology make it an ideal unit for PC board assembly and manufacturing. Its modular design, automatic board handling machine, unlimited feeder life check, robotic arm, vacuum station and wood pallet handling conveyor all work in tandem to offer users maximum flexibility, high accuracy, and efficiency.

There are no reviews yet