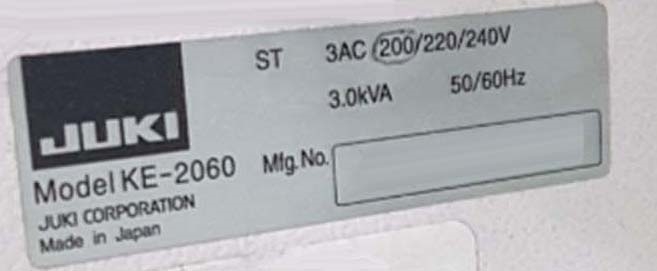

Used ZEVATECH / JUKI KE 2060M #9252890 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2060M is a high-performance PC board assembly and manufacturing equipment designed to meet the needs of high-speed, high-quality, and efficient production. It features an advanced XY-axis placement system with rotational capabilities and high-speed motion capabilities, providing precise placement accuracy, fast product changeover times, and high throughput. To ensure the highest possible quality, JUKI KE 2060M features vision-based solder paste inspection, which provides fast and accurate solder paste detection. The machine also includes a Z-Axis alignment unit which allows precise alignment of the components to the solder paste prior to placement. The machine is also equipped with advanced, high-speed motion control, allowing it to achieve placement frequencies of up to 60,000 CPH. ZEVATECH KE 2060M also includes an Intelligent Mixed Feeder Machine (IMFS) to increase production capacity and reduce setup time. It has 8 nozzles and 16 feeders that can be configured in a variety of ways, allowing for a variety of different component sizes and shapes to be handled. Mixed component feeders, single component feeders, reel feeders, tray feeders, and box feeders can be utilized. To further ensure accuracy and consistency of the components, KE 2060M also features high-resolution, high-speed, 3D imaging fiducial camera and pattern recognition tool. This drastically reduces the setup time, increases reliability, and ensures higher yield rates. The machine has an embedded motion control asset which simplifies the programming process and speeds up production. The model also supports a wide variety of placement accuracy adjustment functions including height and temperature settings to ensure precise component placement during production. Since it is a modular design ZEVATECH / JUKI KE 2060M can easily be upgraded for future requirements. The machine is equipped with multiple options to maximize productivity such as bulk feeders for high throughput production and after-placement verification systems. Optional Conveyors and Palletizers make it even easier to load and unload the product. Finally, JUKI KE 2060M includes a PC board inspection equipment which inspects the completed assembly to ensure production stability. The optional board cleaning module ensures that any contaminants on the board are completely removed before processing. This ensures that the finished product meets the highest levels of quality control standards.

There are no reviews yet