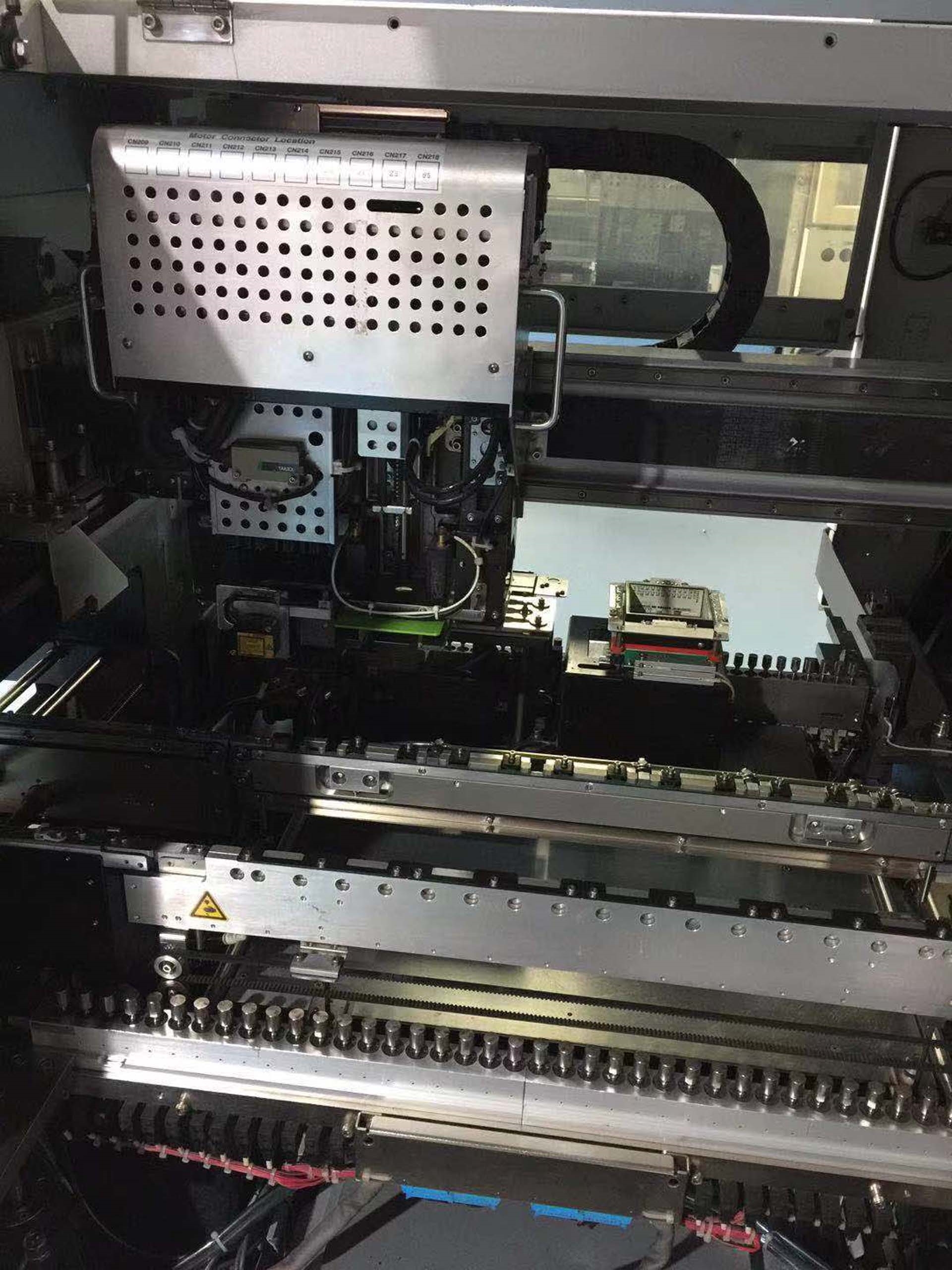

Used ZEVATECH / JUKI KE 2060RL #9234409 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 2060RL is a state-of-the-art pc board assembly and manufacturing equipment designed to produce electronic products with maximum efficiency, accuracy and speed. The system is designed with a productivity of up to 12,000 cph, which allows manufacturers to rapidly produce high-quality products with minimal-cost. It is built with a vision control unit that integrates board placement and inspection in one process, making it extremely reliable. It also offers a wide range of product placement and changeover capabilities, as well as a range of feeder formats and accessories, making it highly versatile and compatible to most applications. JUKI KE 2060RL is powered by its advanced control machine, designed to provide accurate and repeatable production operations. The key components of the tool are its servo motors, servo drives, and control asset with a GUI interface, all of which are designed for repeatable electronic product movements and placement, allowing for ease of changeover and automation. Moreover, it also includes user-friendly automatic feeder calibration and height adjuster. Additionally, a variety of I/O interfaces are provided for fieldbus communication, such as Ethernet, Profibus, and DeviceNet, allowing for integration with different industrial networks. The model includes an onboard ESD protection, which is designed to protect components against electrostatic discharge. It also includes an onboard solder paste printer, which is used for the demountable printing of SMT components onto PC boards. The equipment has an onboard optical inspection system as well, that is capable of recognizing even the tiniest defects on components and boards, allowing for maximum yield. Furthermore, it also has integrated components and board monitoring, enabling quality control and management. ZEVATECH KE 2060 RL also has an onboard conveyor unit that can transport PCBs from the input to the output section of the machine. This allows for improved efficiency, as components and boards can be placed while the board is in motion. The integrated conveyor also allows for various rework operations along the way, as it is equipped with a stop and go mode. Moreover, various substitution and vision centering accessories are included for precise component placement requirements. KE 2060 RL is built to provide stable and repeatable production operations with maximum efficiency, accuracy and speed. With its integrated vision tool, automatic feeder calibration, ESD protection, solder paste printer, optical inspection asset, integrated board monitoring, and conveyor model, it provides manufactures with a complete package while also being user friendly in terms of operation and maintenance. Additionally, it is backed by a reliable customer support services that ensures uninterrupted production operations.

There are no reviews yet