Used ZEVATECH / JUKI KE 2080L #9071127 for sale

URL successfully copied!

Tap to zoom

ID: 9071127

Vintage: 2009

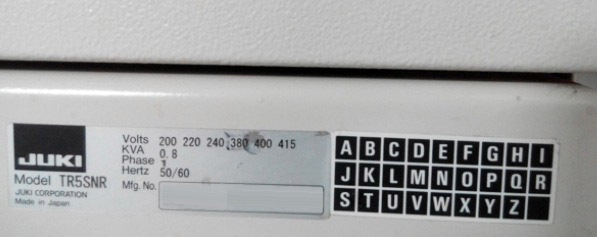

Chip mounter

Feeders not included

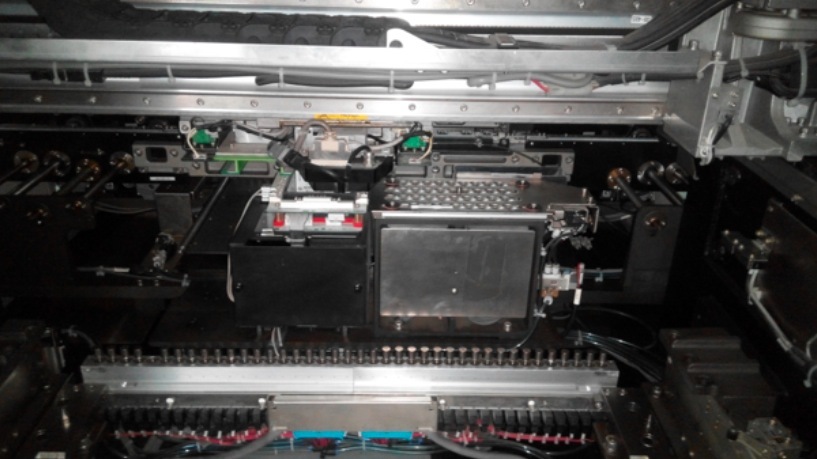

Tray unit

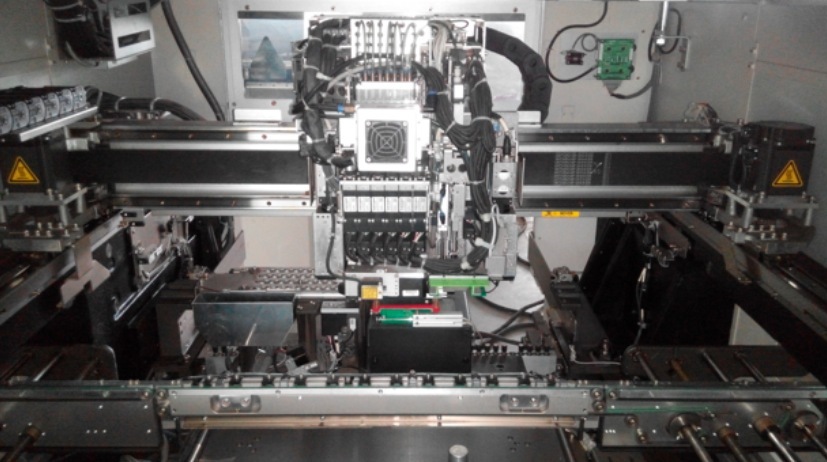

Flow configuration: front fixed, left to right or right to left

Side mount MTC (matrix tray changer)

Camera configuration: fine pitch

Nozzles included: 7 Pcs

2009 vintage.

ZEVATECH / JUKI KE 2080L is a PCB Assembly and Manufacturing equipment designed for high-volume production. The unit utilizes high-precision and high-stability components, along with custom designed and manufactured feeding mechanisms that are designed from the ground up for JUKI KE 2080L. The result is an optimized placement process that enables repeatable, high yield placements. ZEVATECH KE 2080L utilizes multiple Pick and Place nozzles and placement heads to build PCBs faster than ever before. Pick and Place heads mount onto an XY stage and can rapidly move between feeds and placement locations. The Optional 2-Head multi-nozzle Pick and Place system offers a unique solution for quickly assembling PWBs. With up to 180,000 cph cycle speed, KE 2080L offers industry-leading assembly speed performance. ZEVATECH / JUKI KE 2080L has a range of available feeders to accommodate a variety of components, including SMT and BGA devices. Feeders automatically supply components to the Pick and Place heads efficiently, with minimal waste and downtime. The Feeder Heads can be optionally equipped with JUKI advanced Feeder Management Unit, providing an extended life and consistent feed performance. Using a tower-type reflow oven, JUKI KE 2080L is designed to overcome many of the typical limitations of low throughput, high costs and frequent downtime associated with manual solder paste printing and reflow oven processes. The highly efficient design of the unit controls thermal profiles for optimal results, and allows for a variety of complicated profile requirements. Additionally, the unit features high-temperature heating zones for each of the intensive profiles, as well as a Nitrogen Purge control mechanism for oxidation prevention. ZEVATECH KE 2080L also features a PCB Unloader and Handler machine that allows for the safe, efficient and effective handling of Built and Unbuilt PCBs. The unloader is designed to be integrated into an automated line, providing a low-profile, low-space solution to assembly line operations while its integrated stack sensing tool ensures that components are placed with exact precision. KE 2080L provides the speed, flexibility and accuracy required for fast-paced production of intricately designed PCBs, making it a great choice for high-volume production environments. The intelligent design and high-end components ensure long-term reliability and cost-effective operation.

There are no reviews yet