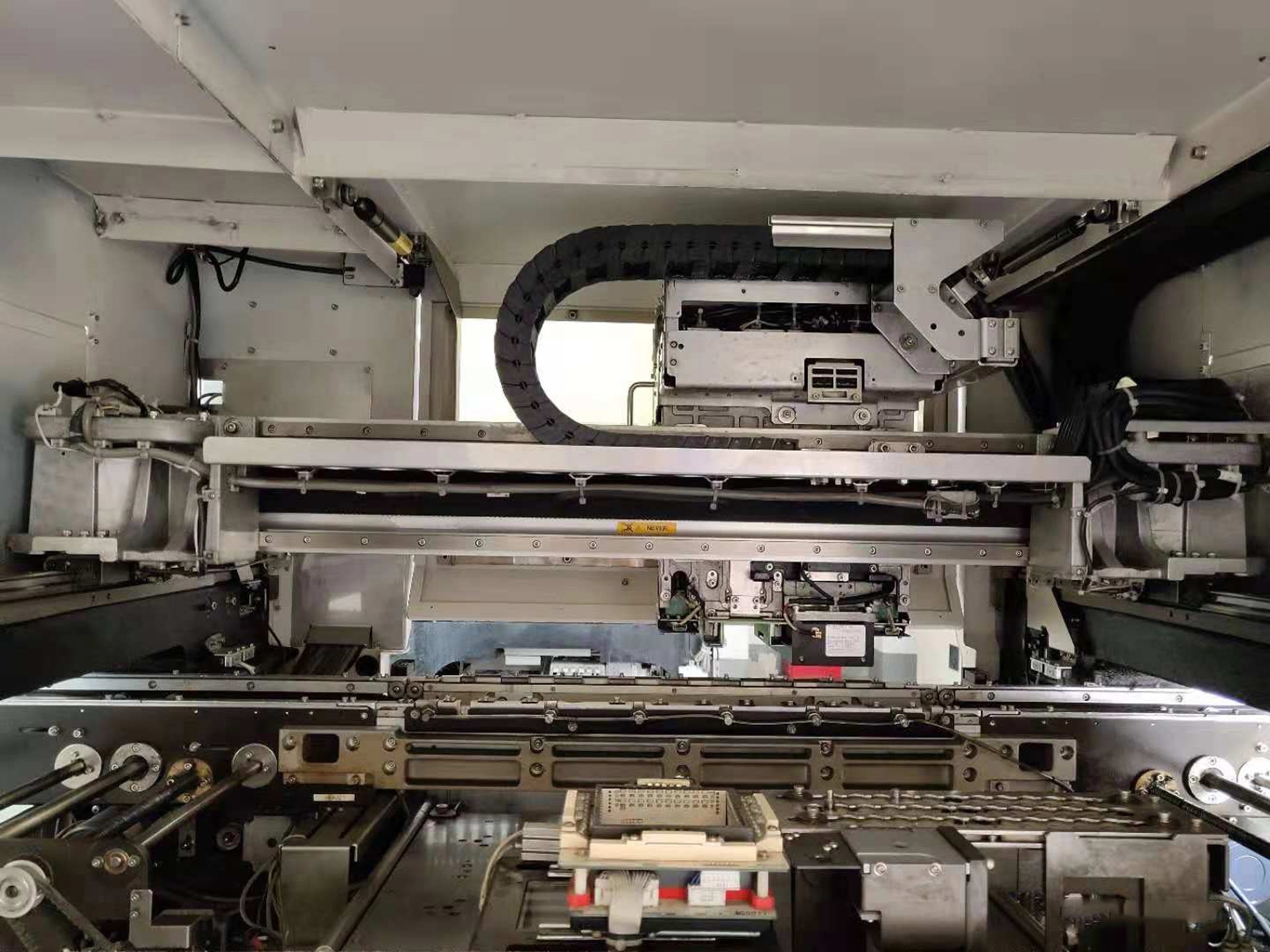

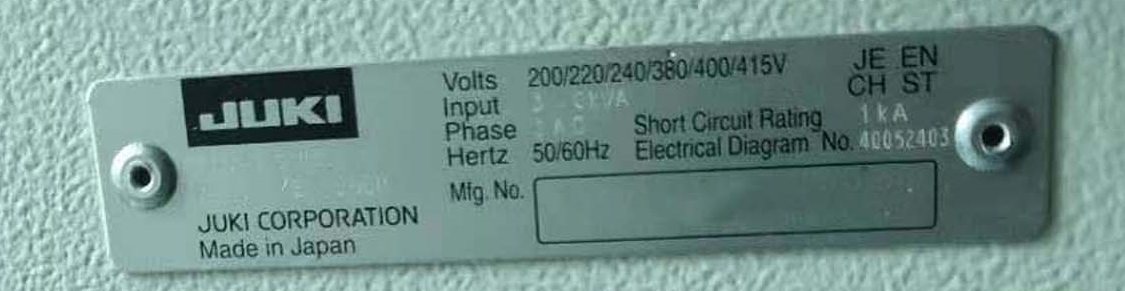

Used ZEVATECH / JUKI KE 2080L #9217849 for sale

URL successfully copied!

Tap to zoom

ID: 9217849

Vintage: 2010

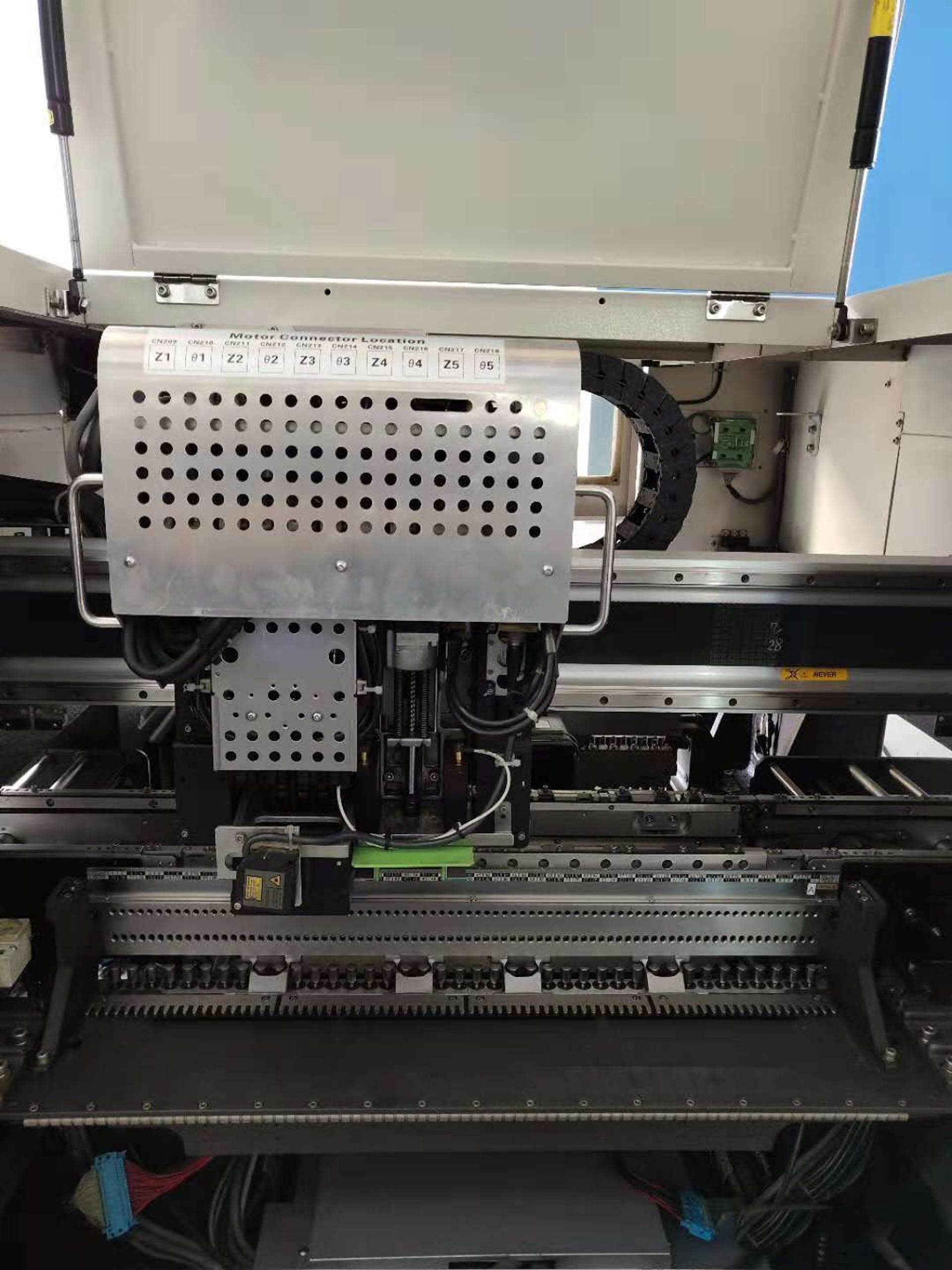

Pick and place machines

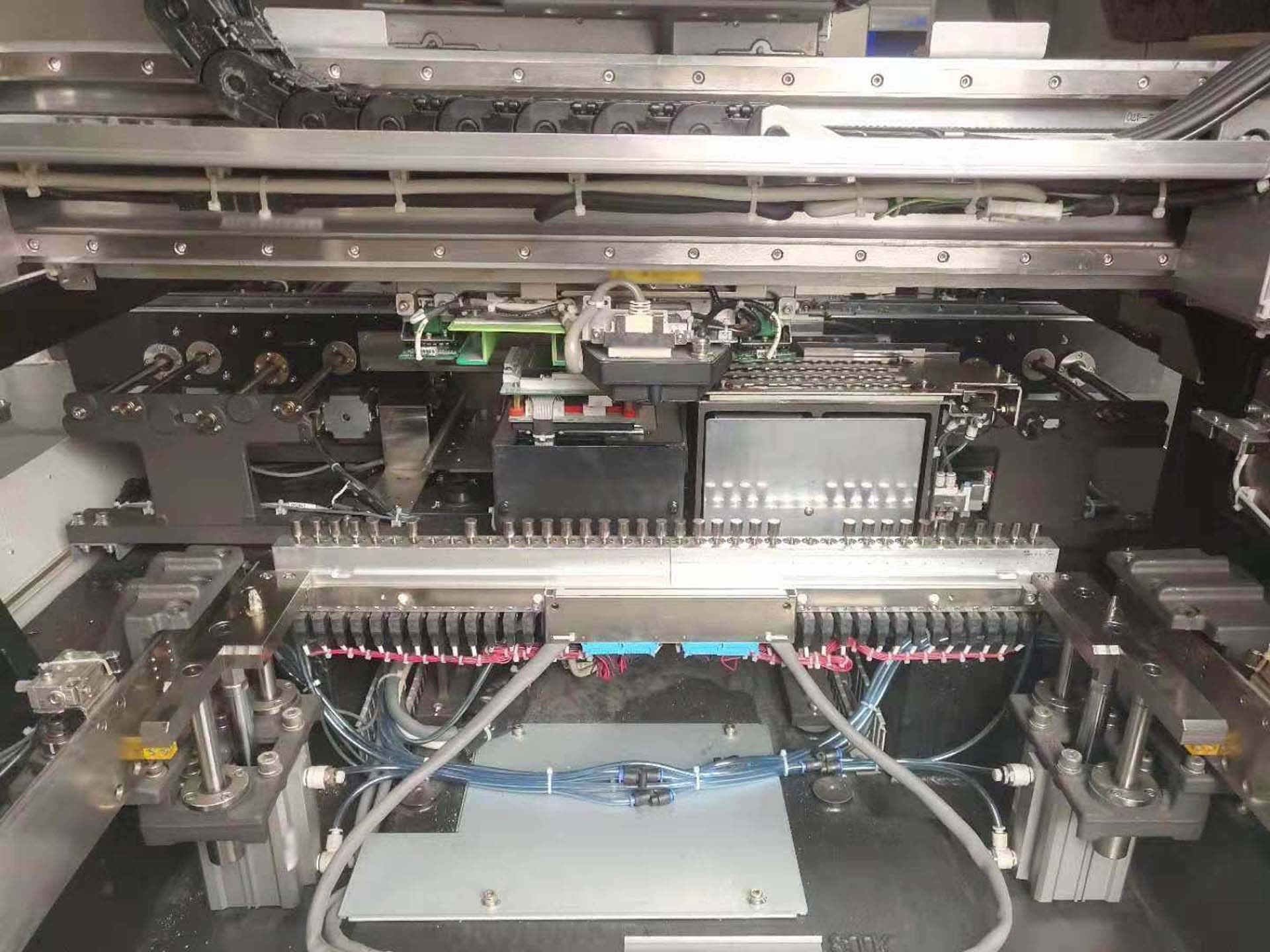

With direct tray

Feeder carts

L to R

Front fixed

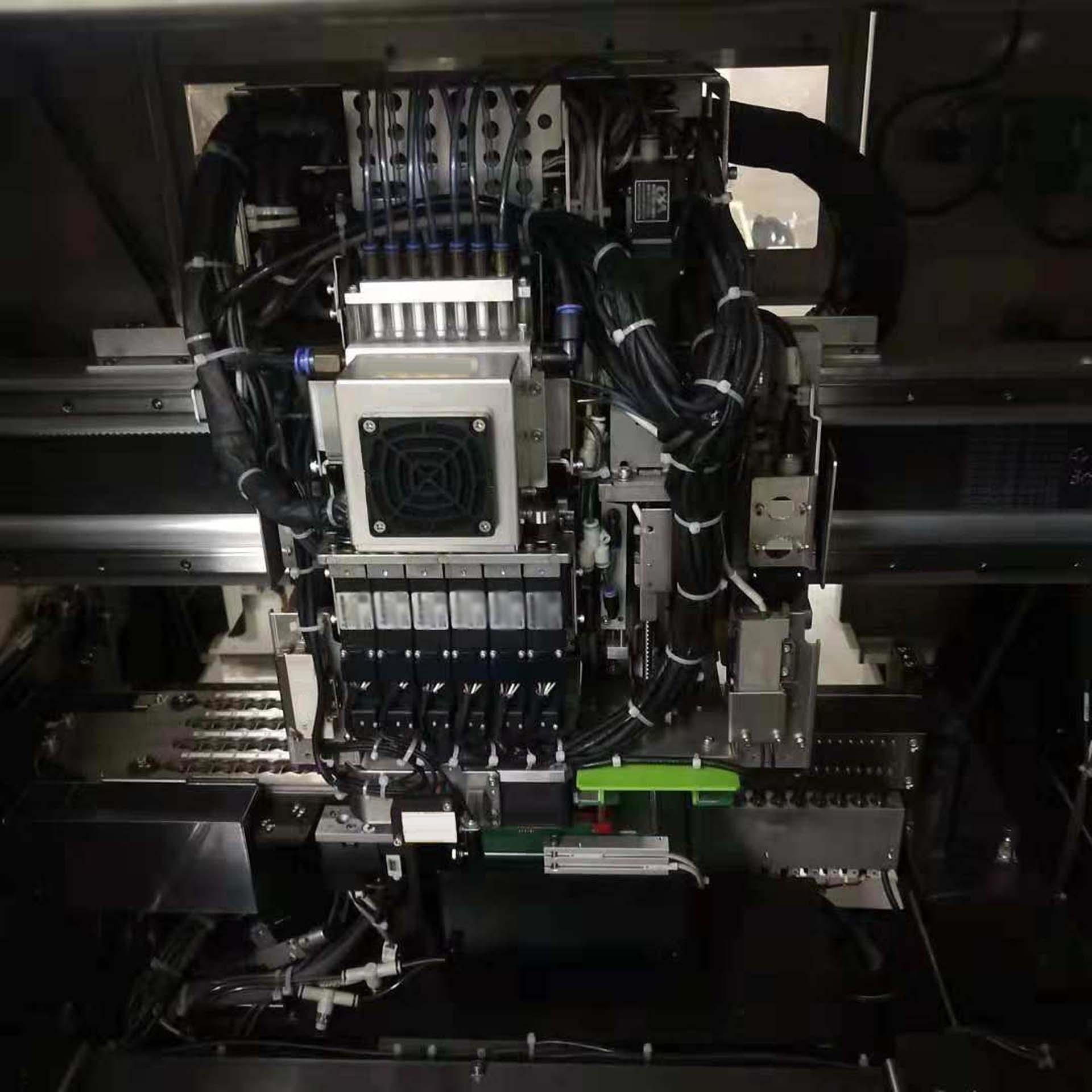

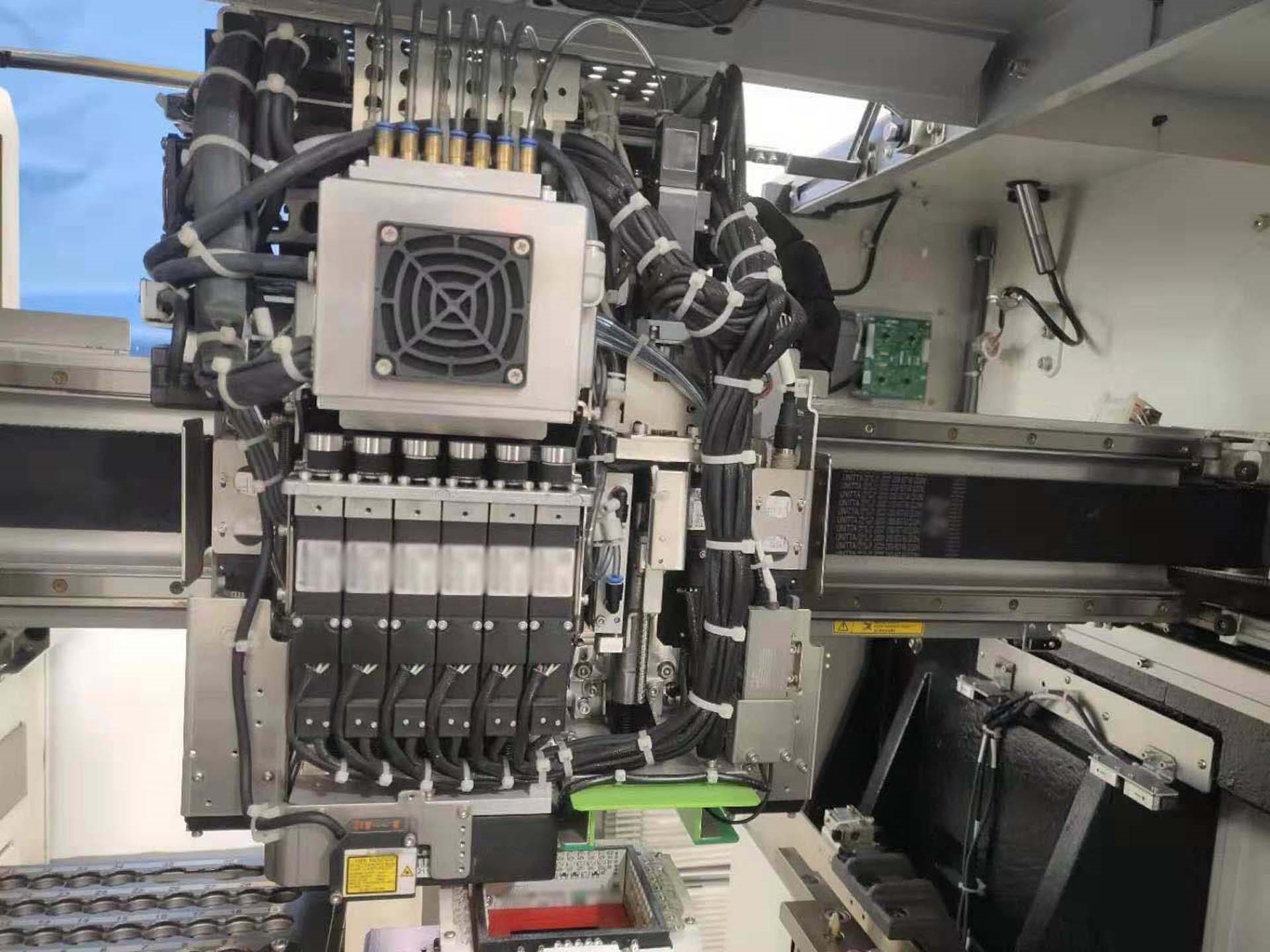

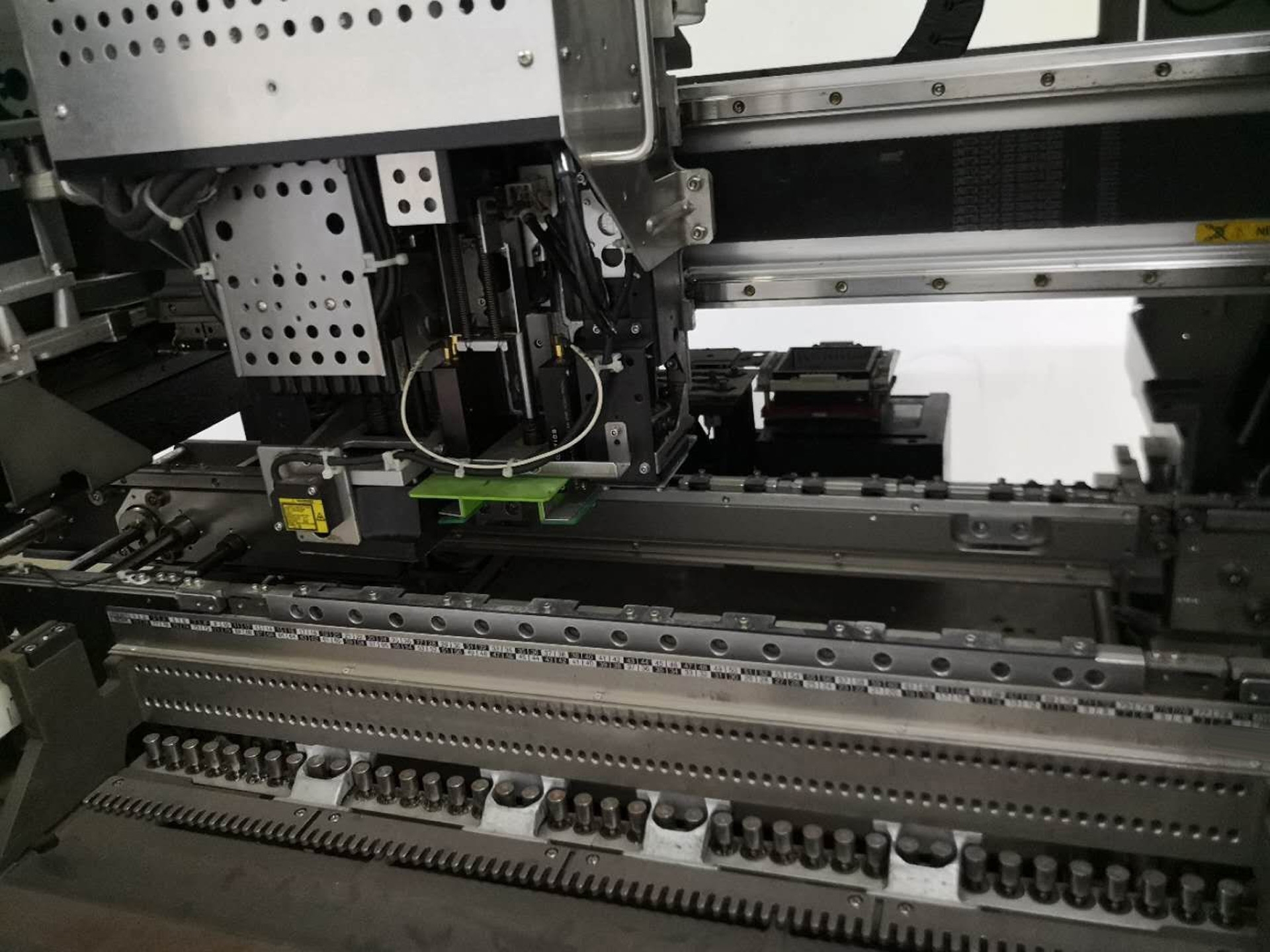

Fine pitch fixed camera

2010 vintage.

ZEVATECH / JUKI KE 2080L is a unique PC board assembly and manufacturing equipment designed to streamline and automate many processes used in the production of printed circuit boards (PCBs). This system brings together a highly accurate pick-and-place head, advanced vision systems, and automated material handling with efficient software to provide a complete automated manufacturing solution. The advanced vision unit uses two sophisticated cameras with integrated lighting to accurately identify components and place them on the board. The placement accuracy is up to 0.04mm, allowing for even the smallest components to be accurately positioned. The parts are further secured using an integrated automated vapour phase reflow soldering process. This ensures that each component is securely soldered, minimizing the risk of failure. The machine also uses a precision motion control tool for easy and accurate part positioning. It is capable of accurately positioning parts with an accuracy of 0.01 mm, allowing for even the most intricate designs to be precisely manufactured. The asset has customizable process settings, allowing for adjustment of speed, acceleration, and accuracy depending on the production need. Additionally, the software incorporated into this model is capable of performing automated part placement as well as optimising output performance. JUKI KE 2080L is also equipped for smart operator guidance and a fully automated material handling equipment. It uses 2D scanners to identify the components, sort them, and move them to the correct location. This process greatly reduces the risk of parts mismatch due to improper visual recognition. The overall result of using ZEVATECH KE 2080L is an optimally streamlined process, resulting in higher production totals of more efficient, higher yields of quality PCBs. This will make any assembly environment more efficient and increases the speed of the production process. It also helps to minimize errors and reduce costs associated with manually assembling components. KE 2080L is the perfect solution for any production environment requiring an automated and efficient PCB assembly system.

There are no reviews yet