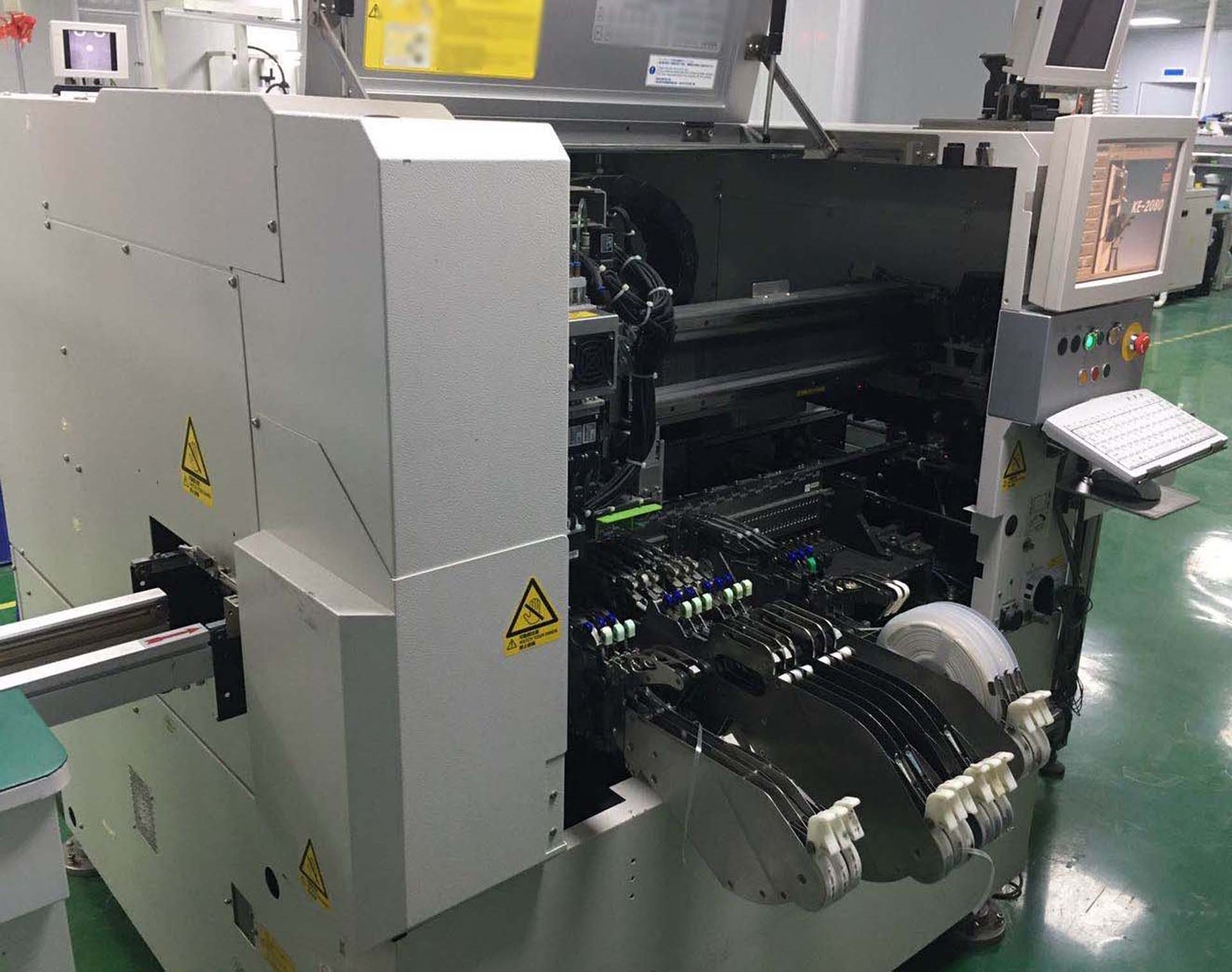

Used ZEVATECH / JUKI KE 2080M #9279444 for sale

URL successfully copied!

Tap to zoom

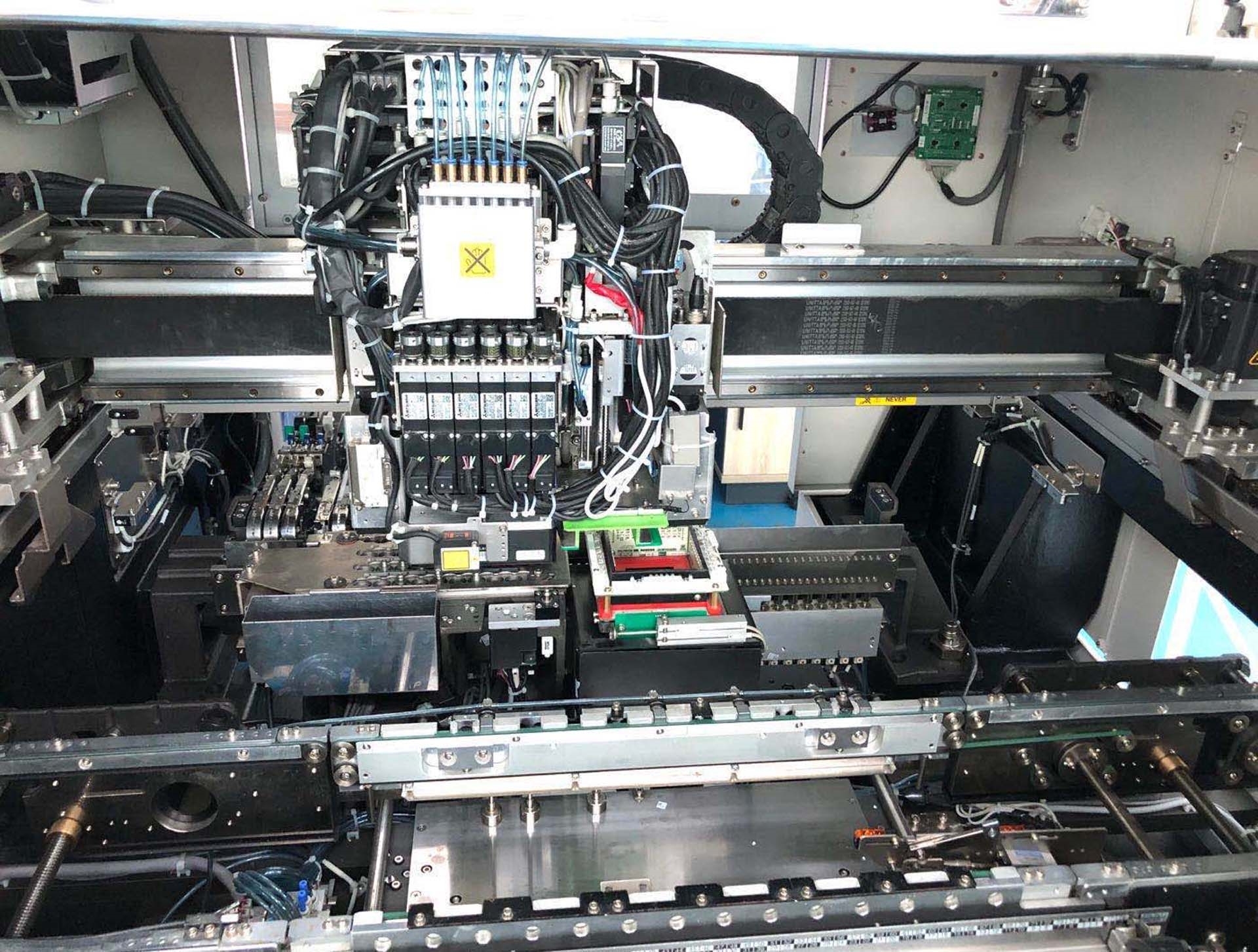

ZEVATECH / JUKI KE 2080M is an automated PC board assembly and manufacturing equipment that offers a wide range of services from prototyping to high-volume production. Designed to meet the needs of electronic manufacturers, JUKI KE 2080M offers the performance and flexibility required for commercial and sophisticated assembly applications. ZEVATECH KE 2080-M is powered by a high-performance CPU with extensive memory and expandable program storage. The powerful main frame ensures precision production, with increased speeds and handling capabilities, and flexibility to incorporate features such as advanced process monitoring and control systems. ZEVATECH / JUKI KE 2080-M's processing and memory are divided into three individual axes, allowing for separate instruction sets and independent processes for each component. KE 2080M is a pneumatically powered automated system. It uses trolley-mounted transport tapes to feed PCBs and component parts to assembly locations. The trolleys, which are capable of extremely precise positioning, run along three guide paths and can store up to 32 PCBs or component parts. The transport tapes are electrically powered and highly accurate, ensuring repeatable movement plus the ability to accurately follow complex assembly paths. The unit's vision sensing capabilities offer comprehensive registration of component bodies, including those with fine lines and intricate patterns. The vision machine can also detect misplaced, broken, or incorrectly oriented parts. As an additional layer of control, the vision tool can be used to detect and reject incorrectly loaded components. KE 2080-M is designed to meet stringent safety requirements. It is equipped with an emergency stop switch that can be triggered at any time, plus extra stop switches on all four axes. It can also be configured with external safety guards and enclosures. All unnecessary movements are shut off while the emergency stop is active. ZEVATECH KE 2080M features a variety of integrated components for further customizing its operation. It is equipped with an automatic laser marking asset for precise labeling of components. It can also be configured with an automatic soldering model for improved PCB assembly. Additionally, JUKI KE 2080-M comes with an integrated traceability software. This software can record detailed information about components, including origin, change history, cycle times, and quality control statistics. This software can also be used to control and monitor parameters such as process speed and pressure. This level of in-depth analysis allows for more efficient and accurate production. In conclusion, ZEVATECH / JUKI KE 2080M is an automated assembly and manufacturing equipment that provides precision production and a wide range of capabilities for commercial and sophisticated electronic applications. Its powerful main frame, pneumatically powered motion system, and advanced vision unit provide great accuracy and flexibility. In conjunction with integrated components for comprehensive traceability, JUKI KE 2080M offers an effective solution for industrial PC board assembly and manufacturing.

There are no reviews yet