Used ZEVATECH / JUKI KE 3020 VAL #9222702 for sale

URL successfully copied!

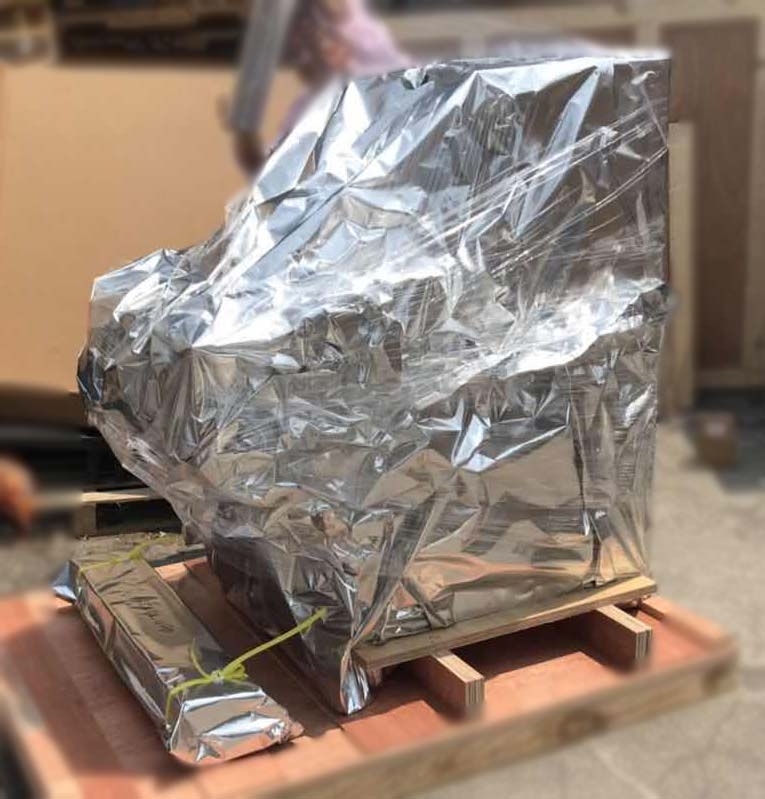

Tap to zoom

ID: 9222702

Chip mounter

With tray TR6SNV

Direction: Front side left to right

(6) Nozzles (502) (1005)

(6) Nozzles (503) (1608/2021/SOT)

Nozzle (505)

Nozzle (506)

Nozzle (507)

Nozzle (508)

Matrix tray changer TR6SNV (Right side setting)

Electronics controller

Color LCD display

Operation panel

PWB Transport system

Placement heads

Laser recognition head (LNC60) L

Offset correction camera (R&L)

MNVC

Component recognition camera (VCS)

Auto tool changer (Type A)

Signal tower

Feeder floating sensor (Front & rear side)

Emergency stop button

Height Measurement System (HMS)

Air pressure device piping system vacuum pump

Safety cover

Backup pin

2 USB Ports

ATX Power supply with UPS function

Power: 220V, 50Hz, 3 Phase.

ZEVATECH / JUKI KE 3020 VAL is a PC Board assembly and manufacturing equipment designed to meet the needs of surface mount and through-hole technology applications. This system utilizes the latest advancements in machine vision to accurately align and place components on the board with remarkable speed and precision. JUKI KE 3020 VAL is capable of handling a diverse range of components up to 0604 pitch sizes. This unit comes with a variety of features to improve production efficiency and accuracy. In addition to a 600 preset placement heads, ZEVATECH KE 3020 VAL is outfitted with 320 nozzle heads that can individually mount any component to ensure quick placement of thousands of components an hour. It also features an intelligent form placement inspection machine that utilizes light curtains to sense the quality of parts placement. Furthermore, this tool supports automatic offline teaching, allowing operators to control the placement process with ease. KE 3020 VAL utilizes a dual conveyor track design. The upper conveyor track moves boards, components, and images while the lower conveyor track transports boards into and out of the placement area. An image capture asset records images of placed components for real-time quality control and certification. Furthermore this model is equipped with an industry-leading scanner that accurately reads bar codes, positional marks, and MIS information. Additionally, ZEVATECH / JUKI KE 3020 VAL can be interfaced with existing equipment to expedite assembly processes. JUKI KE 3020 VAL has a structural frame made from aluminum and steel. This equipment also features advanced vibration control technology, silicone stabilizers, and rotation stoppers, which reduces the amount of vibration and yields more precise component placement. Furthermore, the system has the ability to automatically change its configuration, allowing it to quickly adapt to a variety of assembly jobs. ZEVATECH KE 3020 VAL is intended for use in the highest production environments. Its durable and reliable design allows it to run continuously with minimal maintenance downtime. Additionally, users have access to JUKI full unit maintenance and repair services. This machine is suitable for use in a variety of industries such automotive, medical, industrial and consumer electronics. Overall, KE 3020 VAL is a versatile and high-precision assembly and manufacturing tool optimized for surface mount and through-hole technology applications. This asset is built to minimize vibration, reduce downtime, and increase efficiency and accuracy in component placement.

There are no reviews yet