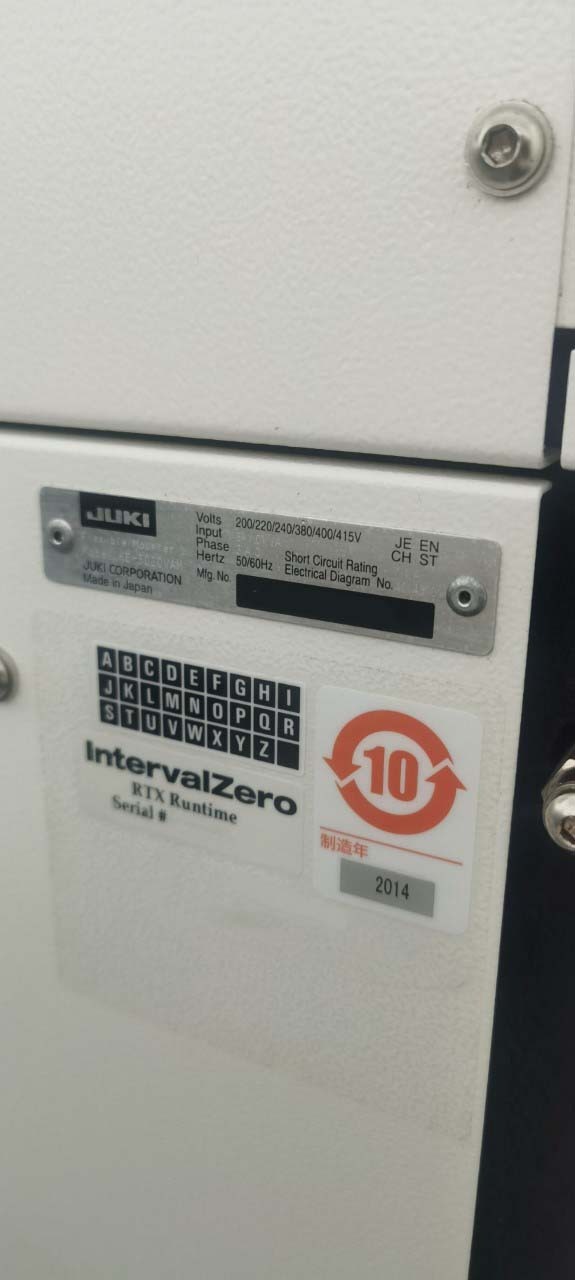

Used ZEVATECH / JUKI KE 3020 #9242654 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 3020 is a PC board assembly and manufacturing equipment designed to be highly productive and easy to use. This system features a high speed vision placement unit that allows for accurate and repeatable placement of components. The high speed motion control machine allows for fast, accurate and reliable placement of components. With a high speed jet nozzle tool, this tool can quickly and accurately apply flux and solder paste onto pads and through-holes. It also features an intelligent Gripper Asset that allows for quick and precise handling of delicate components. The force voltage inspection model is able to detect all types of solder joint defects, such as insufficient solder, cold solder, voids, etc. A scanning laser head is able to identify the type of material being used, as well as the size and placement of the component. The machine is also equipped with an intelligent load-unload monitor which is able to accurately detect the presence or absence of components within a short amount of time. The equipment has a wide range of adaptive programming capabilities. It is able to recognize and respond quickly to different component sizes and shapes. This feature allows for faster and more precise program adjustments according to the components being used. With its high speed motion control system, the unit is also able to accurately recognize sharp turns and small movements which are imperative for assembly and manufacturing. To further enhance productivity, JUKI KE 3020 features a number of automatic functions. By pressing a single button, the user is able to quickly access a number of preset patterns, layers, and soldering parameters. Intelligent error diagnostics are also included to help operators diagnose and rectify any operational errors as quickly as possible. The machine also includes a DoD (deflection of distortion) feature which is able to recognize and respond to any distortions or deflections that might occur during operation. An intelligent tool, it can make sure that any modifications made to a board or component, is carried out in an ideal manner. An automated vision asset is also included, allowing the user to inspect boards quickly and accurately. This vision model can be used when errors are detected or for troubleshooting and repair. The equipment also includes an automated stencil cleaning system, which is able to effectively and cleanly remove any extra solder paste that might be leftover on the stencil after the soldering process. ZEVATECH KE 3020 is a highly productive and efficient unit offering a wide range of features and options. With its high speed motion control, component recognition machine, and intelligent error diagnostics, operators are able to efficiently and accurately assemble and manufacture PC boards with a minimum of manual input.

There are no reviews yet