Used ZEVATECH / JUKI KE 3020L #9282983 for sale

URL successfully copied!

Tap to zoom

ID: 9282983

Vintage: 2011

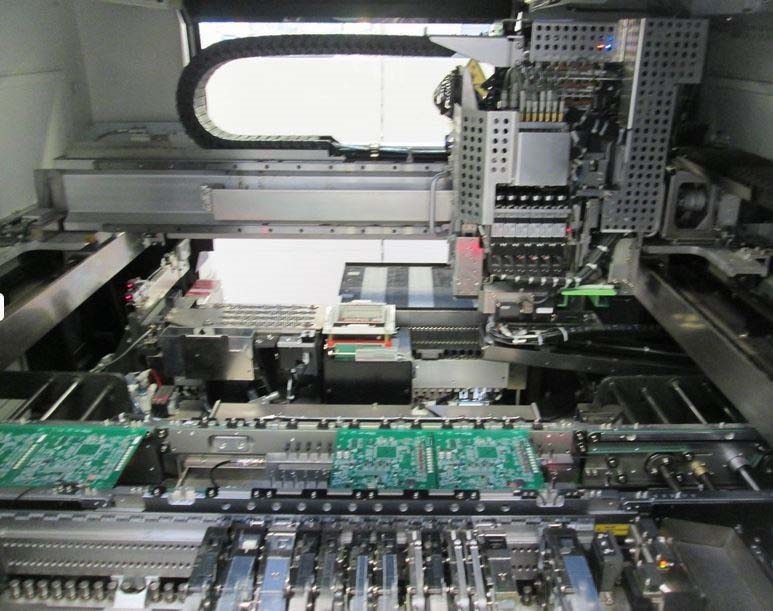

Chip mounter

Laser centering with 6 nozzle heads

Fixed camera

Maximum PCB size: 360 x 410mm

Comp. place: From 01005 to 72mm metric

Max placement speed: 17 Comp/h

MTC Type: TR6

(50) Feeders included

2011 vintage.

ZEVATECH / JUKI KE 3020L is a high-end automated pc board assembly and manufacturing equipment. It is built for maximum efficiency, accuracy and reliability. The system features a component placement unit that utilizes both off-the-shelf and custom components, allowing for greater flexibility. It also features an SMT double-sided component placement machine which facilitates rapid processing of large components. The tool utilizes top-of-the-line component alignment to ensure precise placement and quick turnarounds. JUKI KE 3020L automatically cleans, preheats, and solders components in order to ensure maximum production efficiency. It features a pressure sensitive adhesive (PSA) asset with software that provides a highly accurate and reliable interface between the components and the boards. This precise PSA model ensures repeatable accuracy and reliable connections. The equipment also features a reprogrammable nozzle system, which allows it to be used on a variety of boards. The nozzle unit utilizes variable speed controllers, which allow for both maintenance and multiple board types. ZEVATECH KE 3020L is also able to rotate and shift component placement for up to four assemblies at once, allowing for faster turnarounds. KE 3020L is capable of handling a variety of board sizes and types including but not limited to: FR-4, FR2, FR4/FR2, CEM1, FR4 lamination, and Flexible Circuit boards. The machine also features high-speed visual inspection, eliminating incorrect components. This ensures that any mistakes are detected early and can be corrected quickly. ZEVATECH / JUKI KE 3020L operates on a highly functional operating tool, ensuring the user can easily and quickly navigate the asset. Its user-friendly interface ensures that the model is easy to understand and use, allowing for maximum efficiency and productivity. It also features a statistical process control (SPC) option that gives the user real-time process monitoring and control. JUKI KE 3020L is a top-of-the-line pc board assembly and manufacturing equipment that provides maximum production efficiency, accuracy, and reliability. With its robust software, versatile component placement system, and user-friendly interface, ZEVATECH KE 3020L ensures that any manufacturer can quickly and accurately assemble pc boards quickly and reliably.

There are no reviews yet