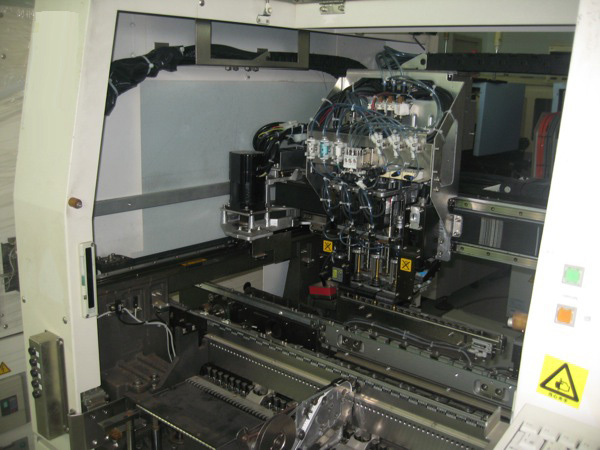

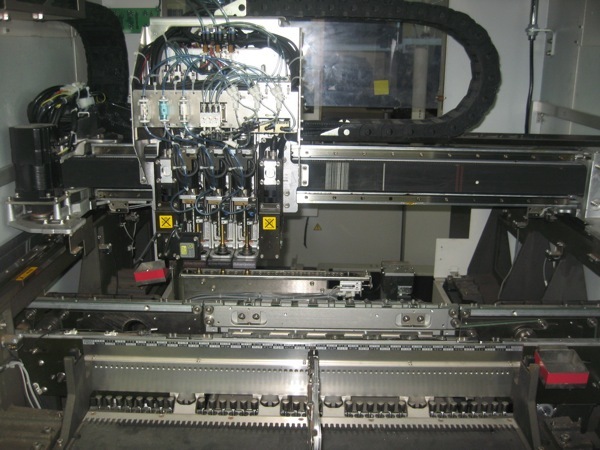

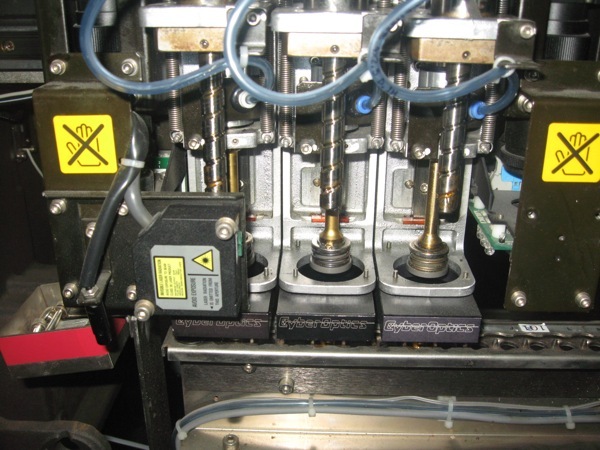

Used ZEVATECH / JUKI KE 750 #154890 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 750 is a high-performance PC board assembly and manufacturing equipment designed to provide manufacturers optimum efficiency, high quality, and cost-effective production. It features a flexible, modular platform that can be configured to meet the specific needs of a production process. Its features and functions include an advanced vision system, a high-speed, precision feeder, intuitive user interface, and a high-precision pick and place unit. JUKI KE 750's vision machine uses JUKI proprietary Z-3D technology to accurately identify and orient components quickly and accurately. An intelligent setup routine processes jobs in real time, automatically verifying the location and orientation of components as it goes. The vision tool's camera can be moved to zoom in on and inspect components prior to placement. The asset's advanced feeder model is ideal for manufacturing high throughput products. It utilizes an advanced pitch sensing algorithm toverify accurate part pick up and placement. The equipment can handle a wide range of components, from 0603/metric size resistors/capacitors to larger odd form components. ZEVATECH KE 750's intuitive user interface allows operators to quickly and easily set up without having to learn a complex program. The color touch screen provides graphic displays of job status and the amount of time left in each process. The user can also create custom profiles, adjust the feeder pitch, and make changes to variables on the fly. The system's high-precision pick and place unit is designed to ensure accuracy and quality. With a +/- 0.0015" (+/-0.0381mm) accuracy, it can place small and large components accurately, without skipping or drifting, even at high speeds. It can also place both SMD and odd form components, and is equipped with a painters board for additional support. The machine's "smooth running" function ensures accuracy at all times. KE 750 is an intelligent, cost-effective tool for PC board assembly and manufacturing. It combines powerful features, advanced vision technology, a high-speed feeder, intuitive user interface, and a precision pick and place asset into one powerful, easy-to-use machine. It is the ideal model for keeping production costs low and quality high.

There are no reviews yet