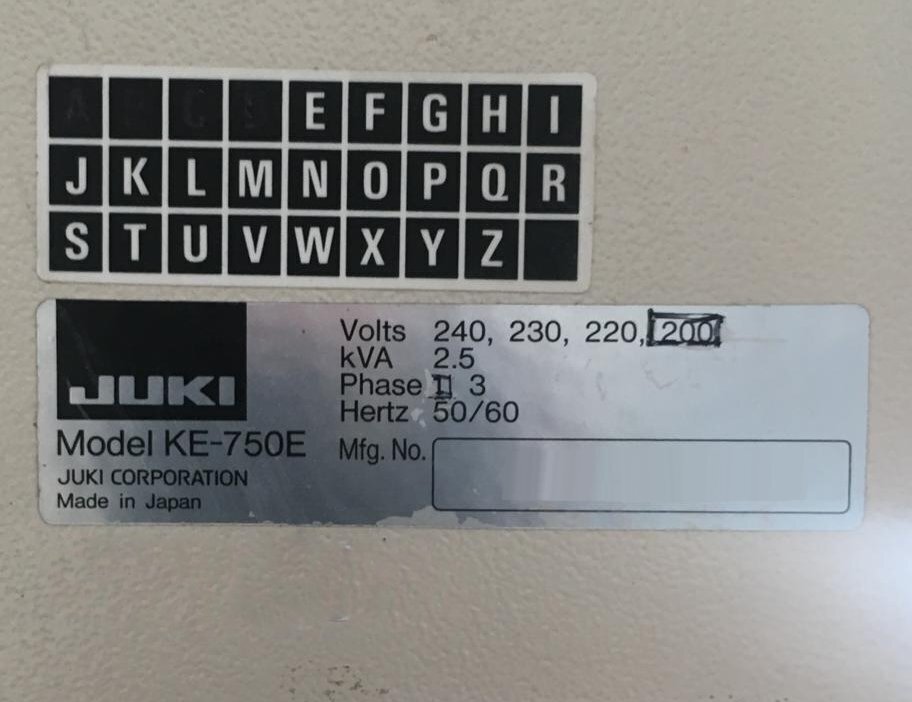

Used ZEVATECH / JUKI KE 750E #9185457 for sale

URL successfully copied!

Tap to zoom

ID: 9185457

Vintage: 2000

Pick and place machine

Speed: 0.25s

(3) Heads

Laser collection

Accuracy: 0.08 mm

Angle accuracy: 0.001 Degree

Thickness of PCB: 0.4 mm ~ 4 mm

Component size:

1.0 x 1.0 x 0.5 mm ~ 32 mm x 11 mm

QFP: 20 mm x 20 mm

Power supply: 220 VAC, 2 kW, 1 Phase

2000 vintage.

ZEVATECH / JUKI KE 750E is a high capacity, high speed intelligent PC Board Assembly and Manufacturing equipment. It features incredibly fast process cycles, high stability and precision, and a number of advanced features to support both manual and automatic operations. JUKI KE 750E is designed to support a wide range of operations, such as soldering, oven reflow, and even equipment maintenance and other parameters necessary to assembly a product. ZEVATECH KE 750E supports multiple machine tools, including up to 12 soldering heads, 15 ovens, multiple peel plate and extractors, and other related work tools. Efficiency is a key feature of the machine, with powerful circuit heater, tight temperature control, and a speedy transport system that leverages multiple magazine loaders and vibratory feed systems. Plus, the machine capacity is easily adjusted depending on the production process, as it features variable speed loading and unloading. For safety and ease of operation, KE 750E has intuitive user interfaces, an automatic self-detection process, advanced parameter settings, and recipe-based parameter settings that facilitate both manual and automatic operations. The machine is equipped with a NAVI (Newly Advanced Vibration Isolation) unit for added process stability, helping to minimize any power interference and other disturbances. Also, a Flexible teaching machine allows production flow settings tailored to the application. To help optimize performance and yield, ZEVATECH / JUKI KE 750E has advanced inspection capabilities. It supports pre-programmed inspection features, including 3D CT scanning, optical inspection, and AOI/AXI inspection for fast, reliable inspection results. Additionally, the tool features sophisticated 3D rotating stage technology that can identify even the slightest differences in parts. Finally, JUKI KE 750E also has remote diagnostics, maintenance, and calibration capabilities, helping to ensure maximum machine uptime. Overall, ZEVATECH KE 750E is an advanced PC Board Assembly and Manufacturing asset that leverages a range of features and technologies to deliver high performance, increased process reliability, and complex product support. With its advanced inspection capabilities, flexible teaching model, and comprehensive remote maintenance offerings, KE 750E provides an all-in-one solution for PC board assembly.

There are no reviews yet