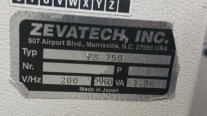

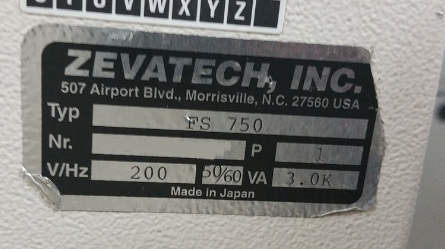

Used ZEVATECH / JUKI KE 750L #9115769 for sale

URL successfully copied!

Tap to zoom

ID: 9115769

Pick and place chip shooter

14" x 16" Board

0201 up to 23.5mm square

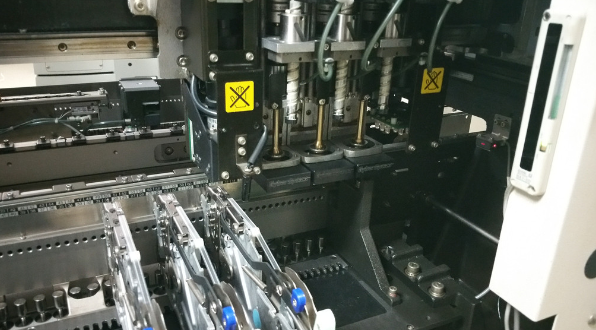

(3) Head

Full compliment of nozzles

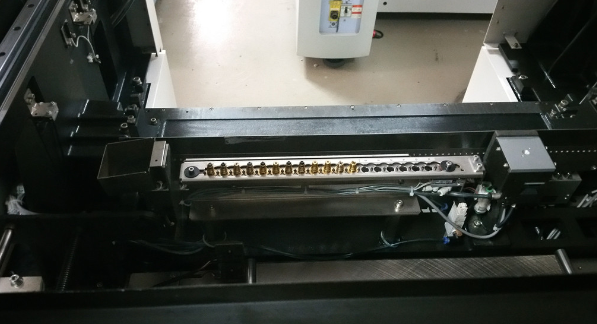

(20) 8mm feeders included.

ZEVATECH / JUKI KE 750L is a pc board assembly and manufacturing equipment designed for automated production. This system can be used to quickly and efficiently produce high volumes of quality printed circuit board (PCB) assemblies. JUKI KE750L utilizes advanced technology to create complex and sophisticated designs. It provides a reliable, efficient, and economical solution for all aspects of PCB manufacturing, from component mounting and soldering to final test and inspection. ZEVATECH KE-750L offers many unique features to make PCB production more efficient. It utilizes a combination of advanced multi-head pick-and-place technology and a variety of vision systems to accurately identify and place components with precision. It employs vision systems for bottom-side component recognition, accounting for varying component footprints, as well as for automated optical inspection (AOI). Its powerful X-Y drive unit accurately moves heavy components on boards, allowing for the creation of complex designs. Additionally, its advanced dispensing technology enables precision placement of components, improving accuracy and quality. ZEVATECH KE750L employs JUKI highly efficient Automated Overlap Soldering (AOS) technology to create reliable solder connections. This advanced process utilizes a combination of hot air and infrared for uniform heating, with a clean and accurate result. Additionally, the machine can be configured with an array of automatic soldering options, such as drag soldering, spiral soldering, and ring segment soldering. KE-750L also includes advanced test and inspection capabilities, with integrated functions such as in-circuit testing (ICT) and functional testing (FCT). It also includes automated optical inspection (AOI) and a laser marking tool for traceability and product identification. ZEVATECH KE 750L is easy to use and maintain, featuring a touchscreen user interface and a modular design. This asset is capable of running with minimal maintenance, utilizing automatic feeders and vision systems to compensate for any defects or wear. It also features a static electricity control model and a fire detection equipment for improved safety. Overall, KE 750L is a powerful, reliable and versatile system for PCB assembly and manufacturing. With its advanced pick-and-place, soldering, inspection and test systems, it can rapidly process even the most complex designs for efficient, accurate and high quality production.

There are no reviews yet