Used ZEVATECH / JUKI KE 750L #9308698 for sale

URL successfully copied!

Tap to zoom

ID: 9308698

Vintage: 2004

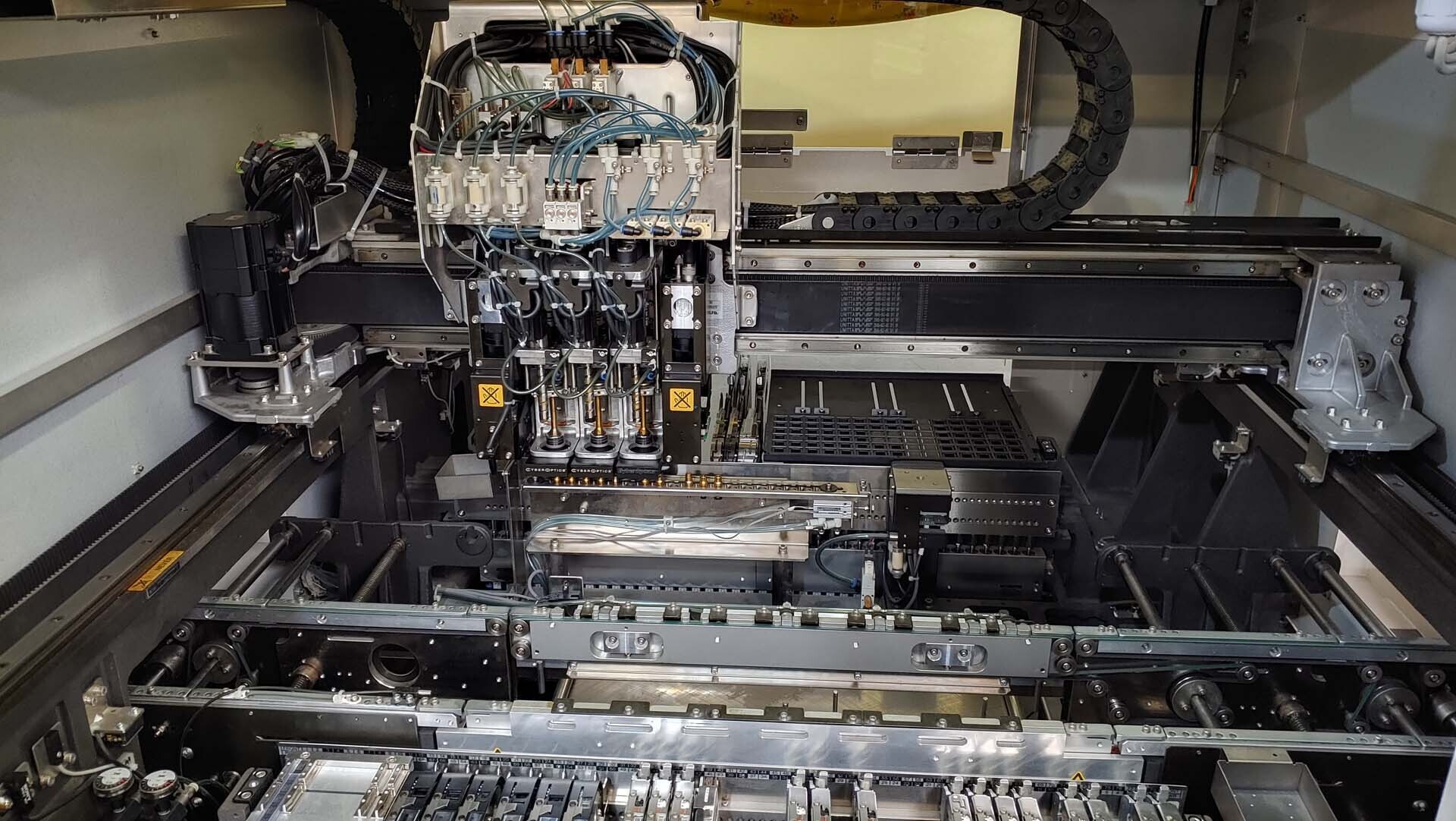

Pick and place machine

(3) Heads

Trolley

(50) Feeders

2004 vintage.

ZEVATECH / JUKI KE 750L is a fully-automated pc board assembly and production equipment designed to facilitate rapid and efficient pc board fabrication and assembly. This versatile system is designed to achieve high quality and low costs. Using advanced control systems to execute multi-stage operations, the unit provides automated board loading, chip insertion, wave soldering, and post-assembly inspection. JUKI KE750L machine is composed of several components, all of which are controlled and monitored by an industrial computer. Its main module consists of a pcb movement station, a board positioner, a teaching box, controllers and a Human Machine Interface (HMI). The pcb movement station includes a conveyor belt, a feeder tool, a pickup table and a reject bin. The board positioner is used for precise alignment of the pc board during processing. The controller unit is a multi-functional device that governs the entire asset's operations. It is responsible for controlling the speed and direction of the conveyor at the pcb movement station and sending instructions to the board positioner. The controller is also capable of reading instructions from the teaching box and controlling the chip insertion head, the wave soldering station and the inspection unit. The Human Machine Interface (HMI) provides the operator with a centralized display and controls the entire workflow of the model. It contains a touch screen with a graphical user interface that helps the operator to program, calibrate and monitor the equipment's operations. ZEVATECH KE-750L is capable of handling up to 100 boards/hour, with a maximum board size of 18" x 24". The system is also highly flexible and can be configured to handle multiple configurations from simple to complex pc board assemblies. In addition to its ease of use, it has high-reliability, resulting in high-yield operations. The unit is designed to meet IPC-A-610 and J-STD-001 standards and provides inspection and reliability assurance to ensure the highest quality of assembly. It also has a variety of safety features and includes a backup machine for fault-tolerant operations. In conclusion, KE750L is a versatile and high-performance pc board assembly and production tool used for rapid and efficient fabrication and assembly. It features advanced control systems, precise board positioning, and comprehensive inspections and reliability assurance. This asset is capable of delivering high-quality results in a cost-effective manner.

There are no reviews yet