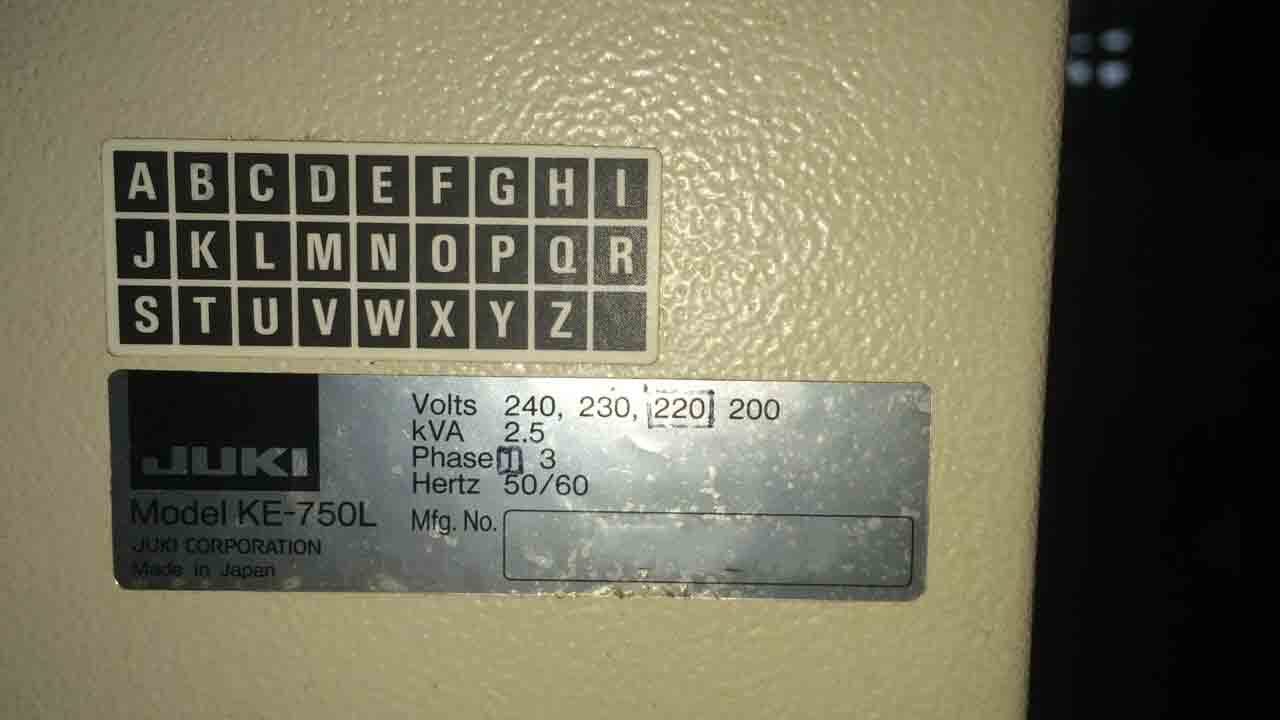

Used ZEVATECH / JUKI KE 750L #9399520 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 750L is a printed circuit board (PCB) assembly and manufacturing equipment that is designed to provide efficient and meticulous production. The system is equipped with a high-speed, high-precision vision unit as well as a multi-functional carrier transport machine. This allows for superior product quality and process control. Furthermore, the performance of the automated processes is optimized for large-scale production of electronic assemblies. JUKI KE750L provides efficient and precise assembly of the components on the PCB. With its high-precision vision tool, it quickly identifies components and precisely aligns them onto the board. To ensure accuracy, the placement head compensates for variations due to component size, shape, and condition. Additionally, the carriers are controlled by the asset to ensure product quality and minimized damage to components. The machine has a built-in multiple function transportation model that is designed to provide maximum flexibility and productivity. This equipment accurately transports boards between multiple processes, quickly and accurately verifying connection points at each new process. This system is also equipped with a flexible conveyor unit that uses two-stage conveyor chains to reduce vibration throughout production cycles. ZEVATECH KE-750L also provides superior engineering support. This support is supplied through an advanced data management machine that simplifies programming and provides fast and accurate data transfer between production and engineering teams. The tool also offers innovative materials storage solutions such as component handling, component storage, and component loading/unloading. In order to ensure optimal production output, KE 750L features advanced vision calibration, component recognition,as well as component placing accuracy. The asset is also equipped with a graphical diagnostics interface that provides graphical overview of complete processes and actual condition of the line. Furthermore, the model can detect component shortages, component quality deficiencies, line process abnormalities, defective boards and detect any other issues that could be affecting the overall production line. KE-750L provides advanced performance in automated production and is a valuable tool for manufacturing PCB. With its precision and advanced features, it is a reliable and effective way to produce high-quality electronic products for a wide range of applications.

There are no reviews yet