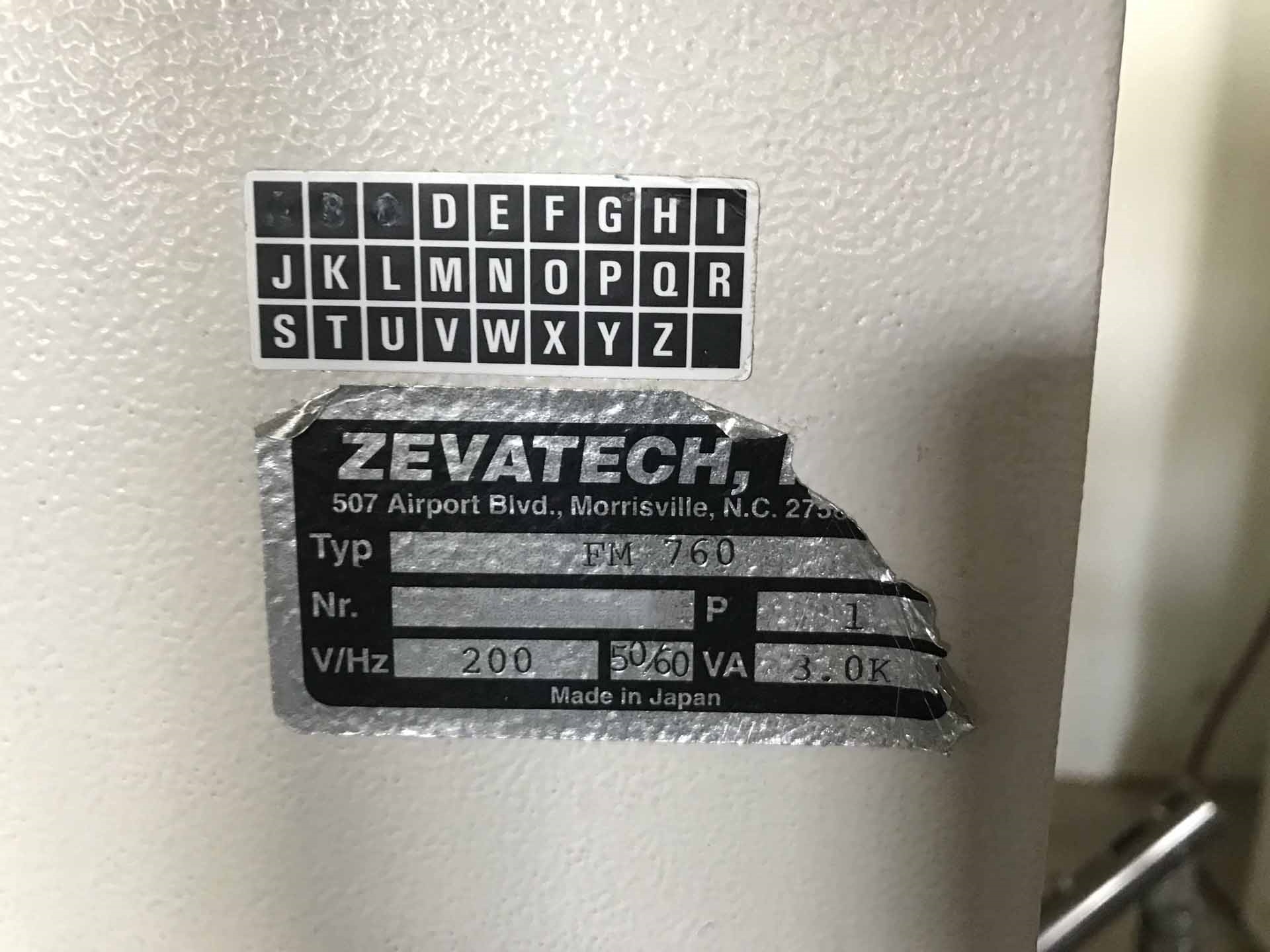

Used ZEVATECH / JUKI KE 760 #9221497 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 760 is a powerful and versatile pick-and-place and printed circuit board (PCB) assembly and manufacturing machine. It can be employed for both surface-mount (SMT) and through-hole (THT) technologies, making it ideally suited for a wide range of production requirements. JUKI KE760 boasts a fast cycle time of 0.6 seconds per component mounting. It is capable of SMT placement speeds of up to 15,000 components per hour and a V-cut scoring speed of 150mm per second. It can handle PCBs up to 510 × 510mm in size and components as small as 0201s, 01005s and CSPs. The machine is poised to take on the most challenging of production requirements. The machine is also flexible when it comes to multi-mounting options. It supports simultaneous placement of up to four components per head, multi-mount capability and a range of mounting materials. It can also support a variety of tasks, including back-filling, mounting of feeder-mounted components, mini-panel assembling and multi-lane component placement. ZEVATECH KE-760 also offers a comprehensive range of software and visual aids to help users monitor assembly progress. The advanced Software Adjustment of Process Setup System (SAPSS) also allows users to easily optimise the production process. Safety is also considered - the machine is enclosed, providing heightened environmental protection, and a number of optional safety functions have been employed to reduce the risk of operator errors. Overall, JUKI KE 760 is an efficient, capable and cost-effective solution for PCB assembly and manufacturing, and is suitable for a wide range of market segments, from consumer electronics to automotive and industrial sectors. It is ideally equipped to meet the most demanding of production needs.

There are no reviews yet