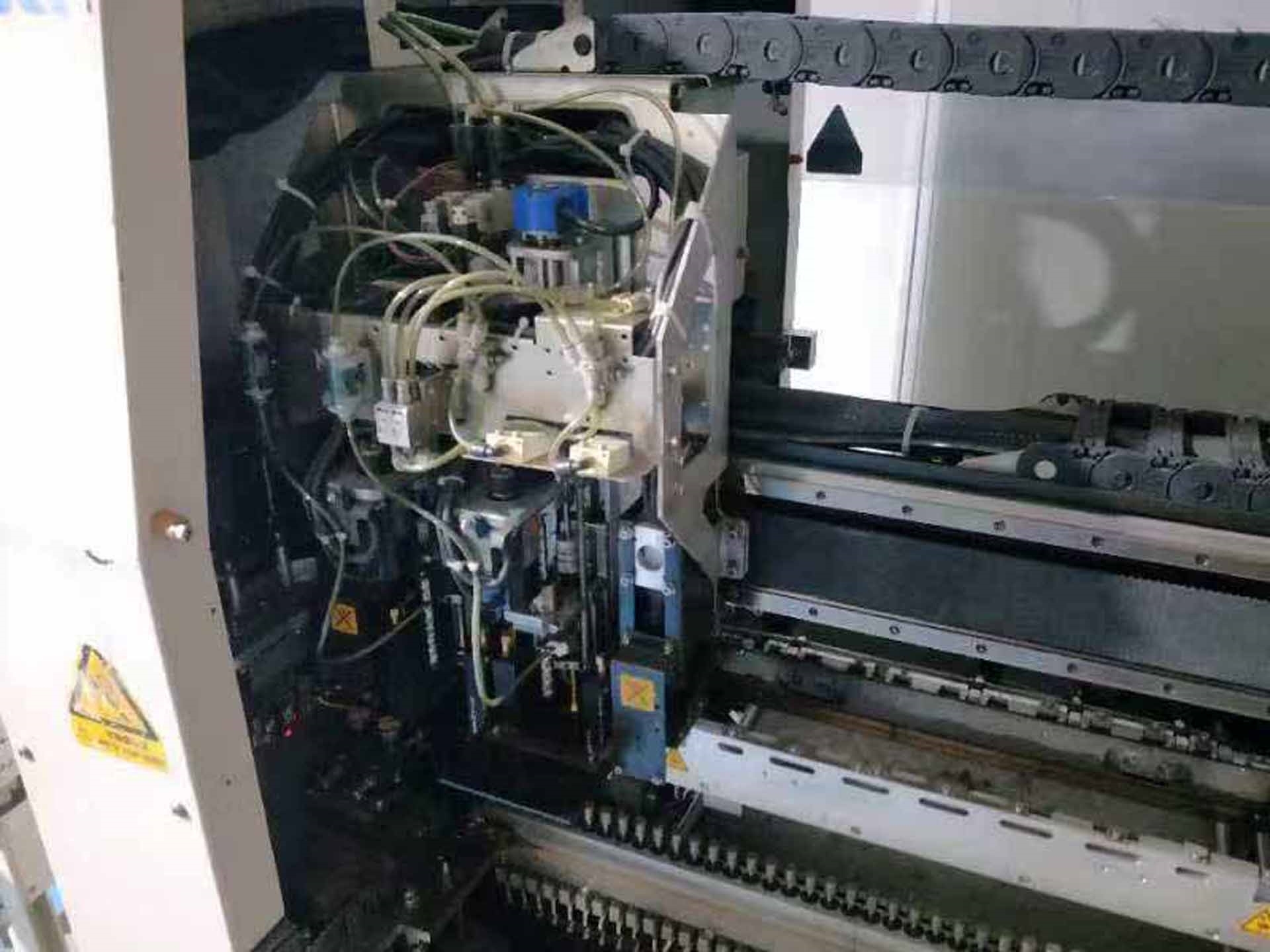

Used ZEVATECH / JUKI KE 760 #9230353 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 760 is an advanced PC board assembly and manufacturing equipment designed to fulfill the ever more exacting requirements of the modern electronics industry. It is the first PC board assembly and manufacturing system to utilize a number of advanced features and technologies to deliver industry-leading performance. At the heart of the unit are two state-of-the-art mainframe units, interconnected via a high-speed communication interface. The mainframes are driven by a powerful single-core processor and have 8 GB of RAM, making them highly capable systems for the most demanding applications. The mainframes are equipped with a full complement of hard drives, as well as a built-in SATA storage interface. The machine is fully compatible with the industry standard Windows operating systems, including Windows XP and 7. Additionally, the tool also supports various Linux operating systems, giving users the flexibility to choose what is best for their individual needs. The asset utilizes a number of advanced manufacturing technology components to increase efficiency and reduce costs. An advanced X-Y pick-and-place machine provides precise component placement. The model also features a selective solder equipment, which can be used for both through-hole and surface mount components. An automated optical inspection system is also offered to ensure quality control. Additionally, an advanced pick-and-place machine is available for the automation of manual operations. The unit also includes a variety of additional tools and features, such as a PC board database that allow users to store their component libraries. It also includes a variety of connectivity options, including EtherCAT and LAN. The machine also includes a number of useful asset management tools, such as a document management tool and an inventory management asset. The model also supports a wide range of automation technologies, including robotic loading and unloading of components, as well as automatic positioning of components. The equipment also offers a variety of traceability options, allowing users to monitor and trace the manufacturing processes. The system also features a variety of quality control options, such as automatic testing systems, vibration monitoring systems, and temperature monitoring systems. The unit is designed to reduce downtime, eliminate manual operations, and improve accuracy and reliability. Additionally, it is designed to enable customers to easily integrate the machine into their existing assembly and manufacturing infrastructure. The tool can be utilized in virtually any manufacturing environment, from small to large-scale configurations. All of these features and technologies make JUKI KE760 a powerful and intuitive PC board assembly and manufacturing asset.

There are no reviews yet