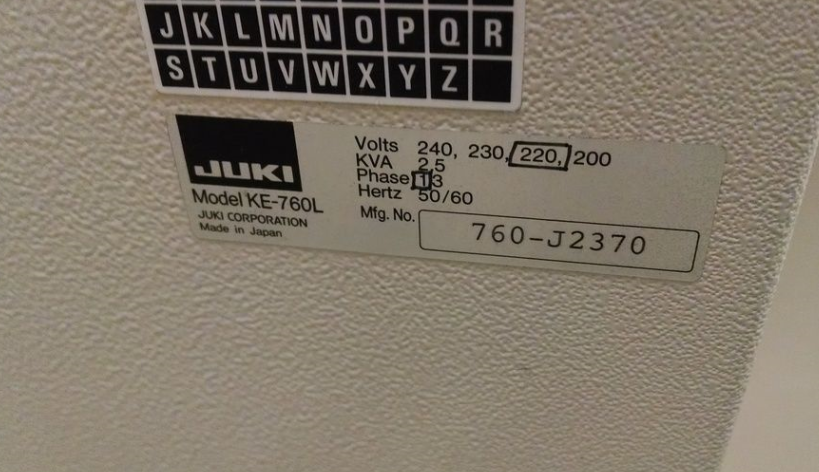

Used ZEVATECH / JUKI KE 760L #9049708 for sale

URL successfully copied!

Tap to zoom

ID: 9049708

Vintage: 2001

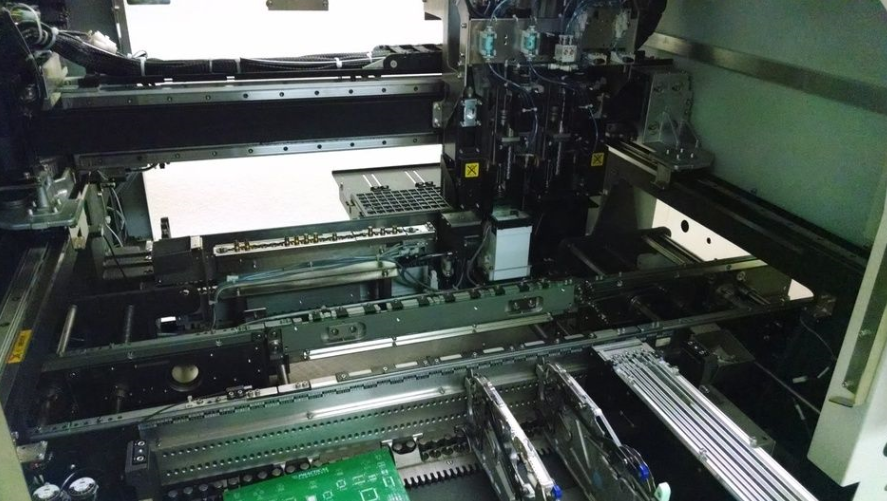

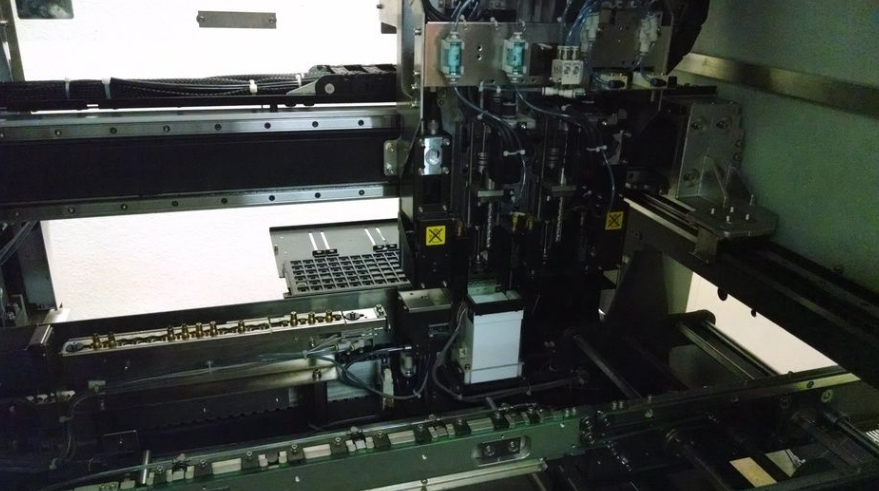

Fine pitch pick and place machine

Automatic high-precision laser placement system for surface mount components

Z height sensor

Feeder float detector

2-Head laser alignment system

Program: maximum 2,000 placements per circuit / maximum 100 non-matrix or 400 matrix circuits per PCB

Self-calibration

Up and down line connection: SMEMA standard

Teach camera

Auto tool changer: the tool changer holds up to (16) vacuum nozzles

Placement heads: (2) high speed assembly heads

Driven by an overhead XY gantry positioning system: closed-loop twin AC servo motors, magnetic linear encoders

Component centering: non-contact centering (TLC) using laser align sensor or upward looking gray scale vision centering

Laser co-planarity inspection option for fine pitch SMDs

Placement accuracy: Laser align: +/-0.0015" on QFPS, +/-0.0039" on chips

Placement rate: 0.32 sec./component

Number of feeder inputs: up to (80) depending on feeder mix

Stack stick feeders:

Hold up to (5) tubes at once.

SOP

PLCC

SOJ

Belt feeder

220 VAC, 1 phase, 50/60 Hz, 3 kVA

2001 vintage.

ZEVATECH / JUKI KE 760L is an advanced PC board assembly and manufacturing equipment designed to automate the assembly process and ensure the highest quality end product. Equipped with an integrated Inertial Motion Control system, it provides precision and accuracy for every stage of the production process. This unit supports the assembly of products with components ranging from 0402 and larger. The machine is comprised of a number of components designed to work in tandem to support the PC board assembly and manufacturing cycle. JUKI KE 760L features an intelligent placement head that offers high speed and repeatable placement accuracy. This placement head is also flexible and can be programmed to accommodate standard and odd-form components. The tool also has a six-axis robot designed to efficiently transfer the PC boards in and out of the machine. Additionally, ZEVATECH KE760L includes a 3D vision asset which is utilized for critical edge and inner layer registration. This model helps to ensure that all components are aligned correctly and any defects are easily identified and corrected. The equipment also features a high speed vision check with a pin-scan function which allows it to detect and mark any incorrect components, as well as verifying the correct functionality of the assembly. KE760L is also equipped with a user-friendly monitor that provides the operator with real-time feedback, making it easy to identify issues with the production cycle. This makes troubleshooting much easier and faster than in manual production. The system also has a convenient remote access port which enables users to monitor and adjust all parameters from anywhere in the world. ZEVATECH / JUKI KE760L has been designed to meet the highest standards of precision and performance. It is ideal for high-mix, low-volume production and can be used to support virtually any assembling process. This flexible and efficient machine is a great choice for any automated assembly production line.

There are no reviews yet