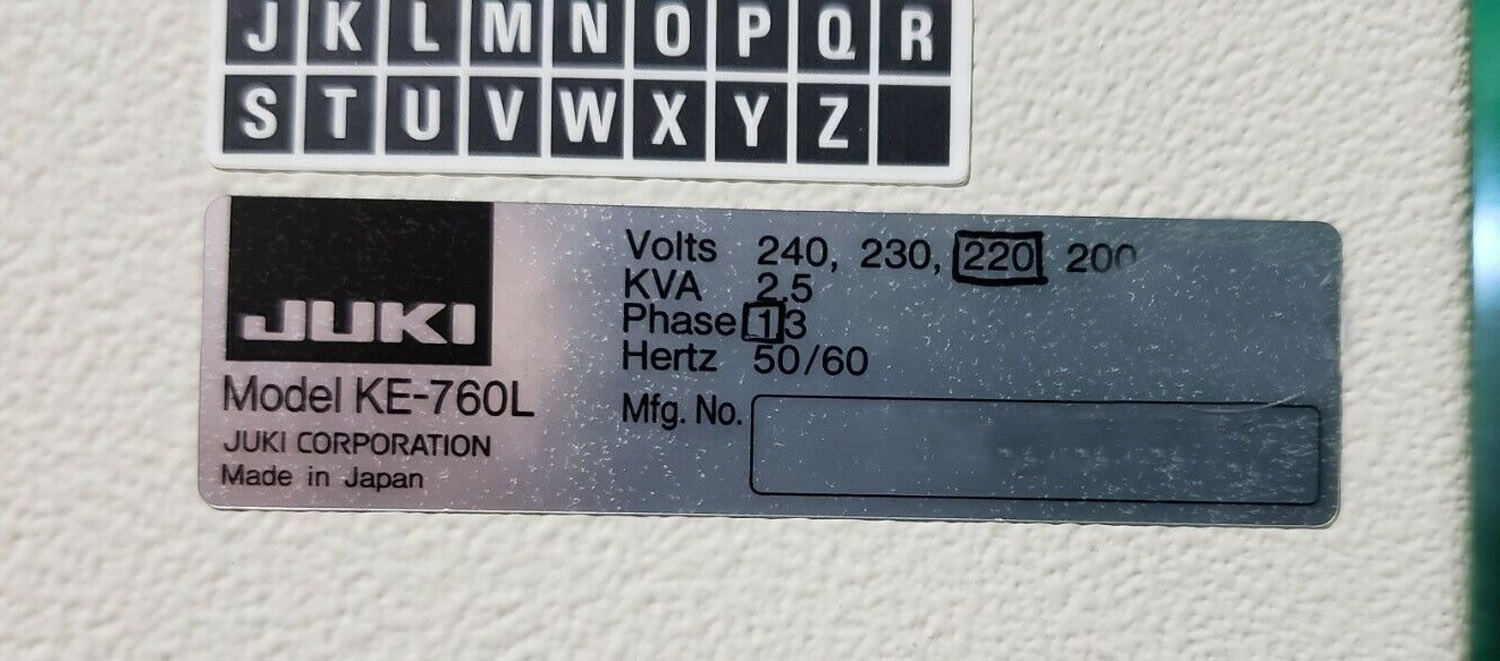

Used ZEVATECH / JUKI KE 760L #9276465 for sale

URL successfully copied!

Tap to zoom

ID: 9276465

Chip mounter

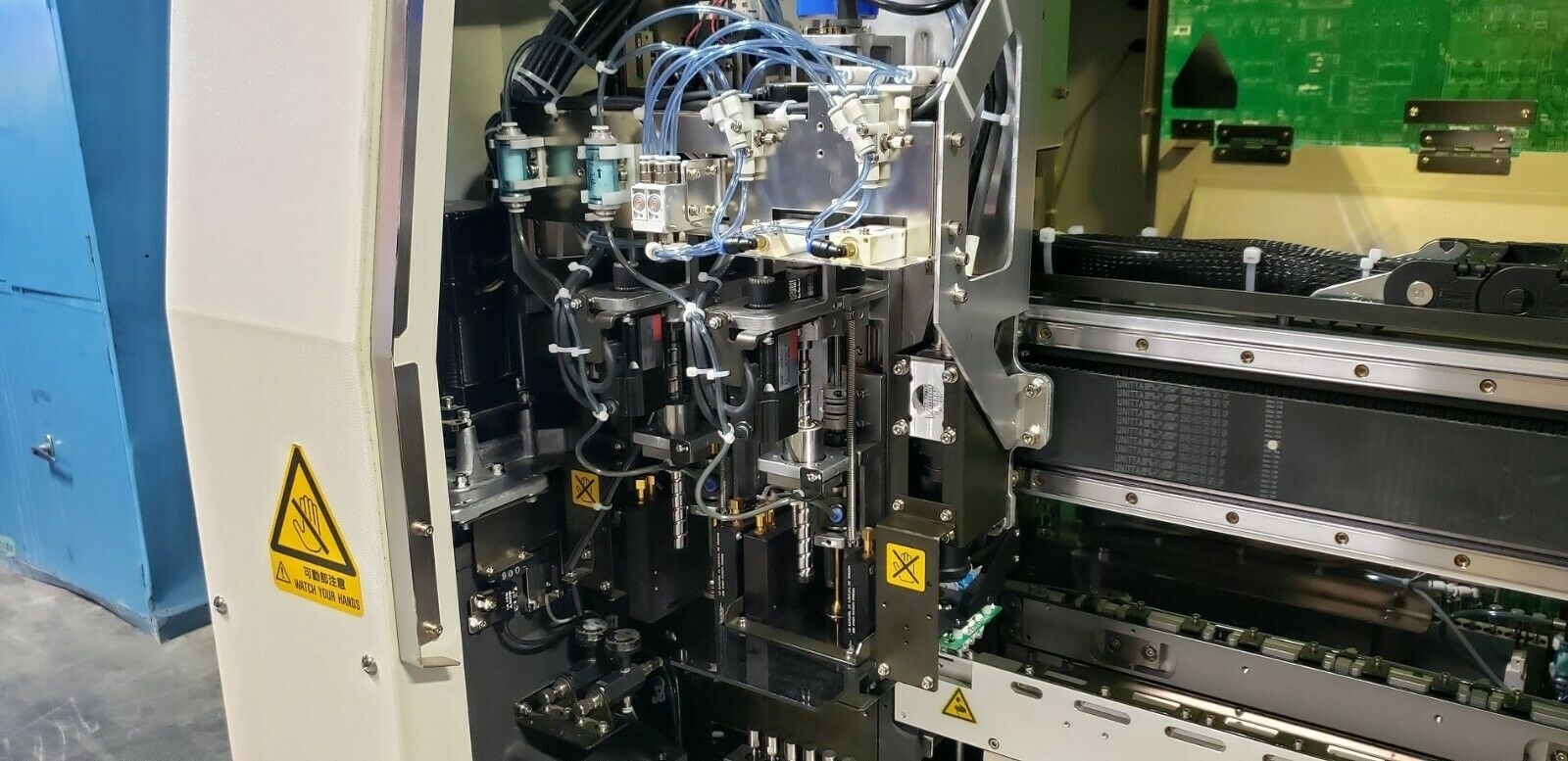

Head: (2) Shafts (JVS2)

Includes:

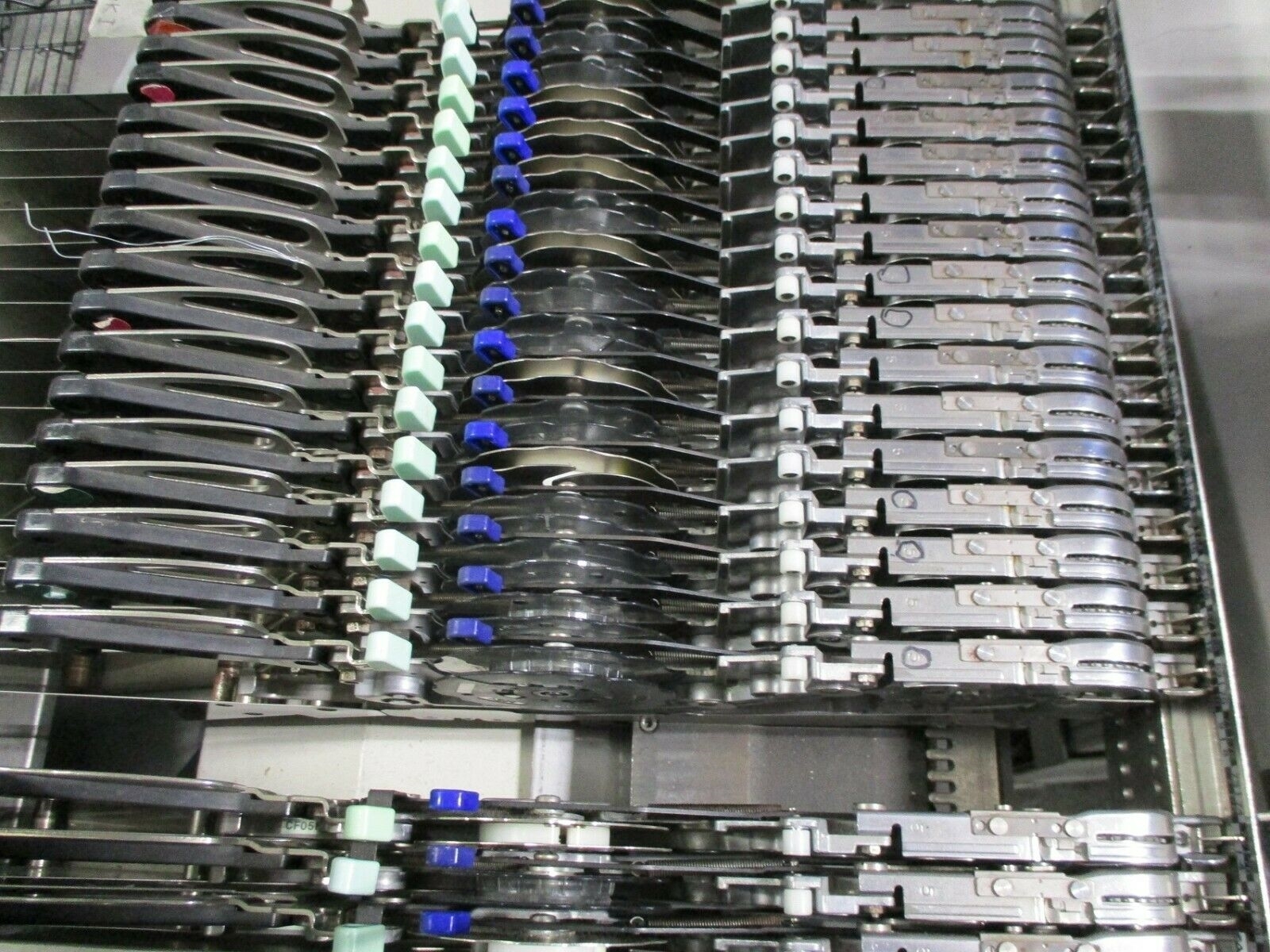

(2) Feeders trolleys

(35) Feeders, 8mm

Feeder capacity: (80) Tape feeders, 8mm

BGA Camera

Feeder float detectors

Bad mark sensor

Front / Rear trolley

PCB Size: 50mm x 30mm - 410mm x 360mm

PCB Thickness: 0.4 - 4.0mm

Component range: 0402 - 50mm² (.3mm pitch).

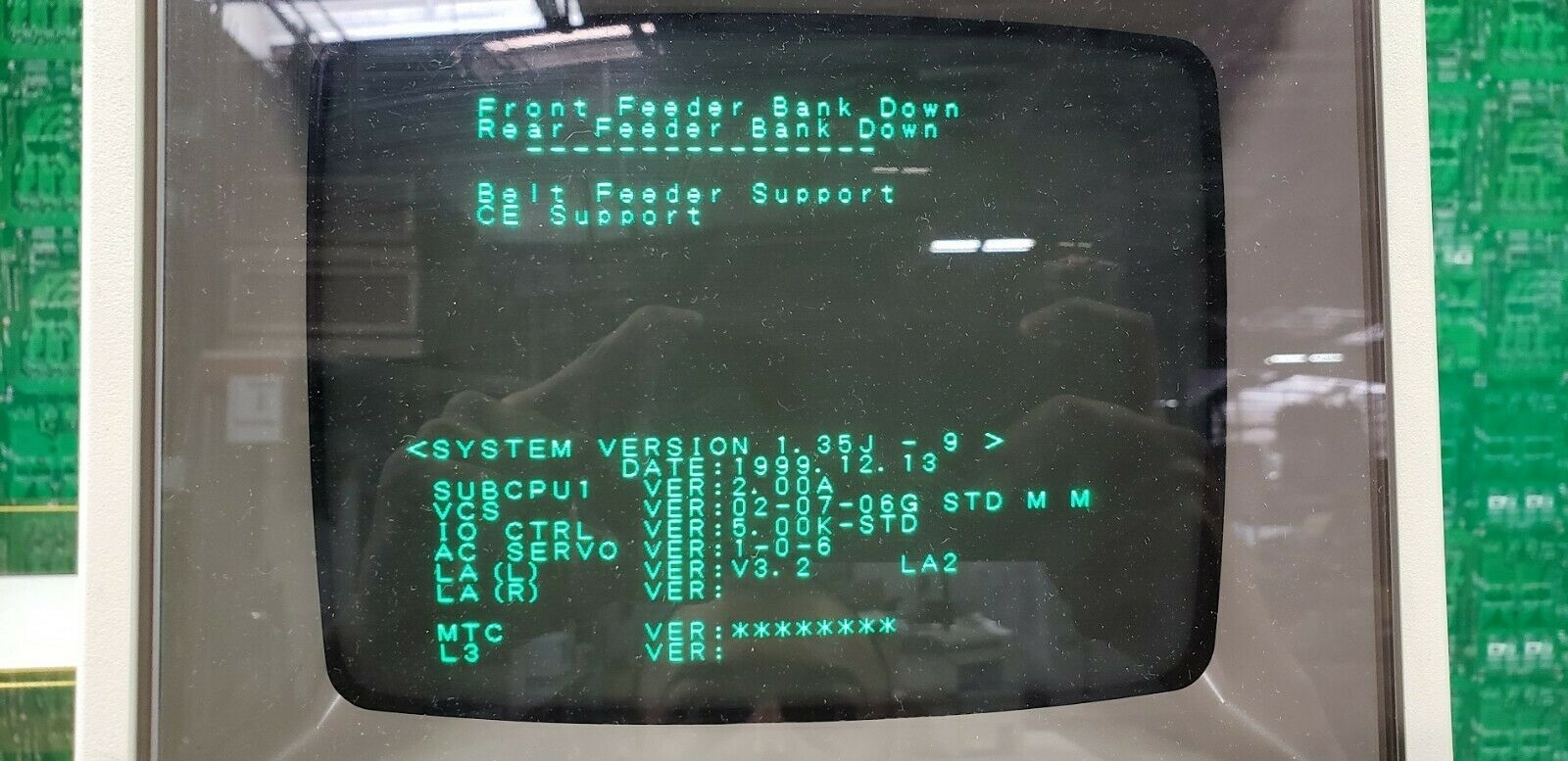

ZEVATECH / JUKI KE 760L is a high-performance, high-reliability, cost-effective PC board assembly and manufacturing equipment. It is designed for automatic assembly and manufacturing of complex surface mount (SMT) components. JUKI KE 760L system features a multi-zone convection heating unit which ensures uniform component reflow, superior surface mount (SMT) placement accuracy, and fast production times. It also features a high-resolution vision machine with advanced post-placement inspection capabilities which performs real-time alignment and quality control of parts. The tool is equipped with a high-speed Euro board transport asset which allows for smooth, accurate, and fast movement from one station to the next. ZEVATECH KE760L also features a patented, customizable, software-controlled component dispensing model which ensures a consistent part accuracy and reliability. In addition, JUKI KE760L equipment boasts up to 16 PC board placement heads and a high-speed board conveyor system with a maximum speed of 1.2 m/sec (4.7 ft/sec). The placement head options include adjustable flying vision inspection, camera triangulation, and laser recognition, which provide accurate inspection of components and prevent mis-placement. The unit also supports a variety of pick-and-place heads such as knurling, needle, and steel ball. It is capable of supporting various types of components such as chips, odd shapes, and complex connectors. KE 760L is equipped with an integrated component library manager which enables quick and easy setup of components for production. It also features an intuitive software-based user interface which allows operators to monitor machine performance, control application settings, and make real-time adjustments. KE760L is an advanced PC board assembly and manufacturing tool that provides high-speed, high-accuracy, and high-efficiency fabrication. Its robust features, combined with its reliable performance and cost-effectiveness, make it an ideal choice for automated assembly and production of SMT components.

There are no reviews yet